Namhlanje, ndiza kwabelana ngendlela yokukhetha i-drill bit ngokusebenzisa iimeko ezintathu ezisisiseko zei-drill bit, ezizi: izinto eziphathekayo, iingubo kunye neempawu zejometri.

1

Indlela yokukhetha izinto eziphathekayo ze-drill

Izinto eziphathekayo zinokwahlulwa ngokufanelekileyo zibe ziindidi ezintathu: isinyithi esinesantya esiphezulu, i-cobalt equkethe i-high-speed steel kunye ne-carbide eqinile.

Isantya esiphezulu sentsimbi (HSS):

Intsimbi enesantya esiphezulu okwangoku sesona sixhobo sisetyenziswa kakhulu kwaye sesona sixhobo sokusika.I-drill bit of high-speed steel ingasetyenziswa kuphela kwi-drill drill ngesandla, kodwa nakwiindawo ezinozinzo olungcono njengoomatshini bokugaya.Esinye isizathu sobomi obude bentsimbi ye-high-speed inokuba isixhobo esenziwe nge-speed-speed steel singenziwa ngokuphindaphindiweyo phantsi.Ngenxa yexabiso layo eliphantsi, ayisetyenziselwanga kuphela ukugaya kwi-drill bits, kodwa isetyenziswe ngokubanzi ekuguquleni izixhobo.

I-Cobalt High Speed Steel (HSSCO):

I-Cobalt-equkethe i-high-speed steel inobunzima obungcono kunye nobunzima obomvu kune-high-speed steel, kunye nokunyuka kobunzima kubuye kuphucule ukuxhathisa kwayo, kodwa ngexesha elifanayo libingelela inxalenye yobunzima bayo.Ngokufanayo nentsimbi yesantya esiphezulu: zingasetyenziselwa ukuphucula inani lamaxesha ngokugaya.

ICarbide (CARBIDE):

I-carbide ene-cemented yi-metal-based composite material.Phakathi kwazo, i-tungsten carbide isetyenziswa njenge-matrix, kwaye ezinye izinto zezinye izinto zisetyenziswa njenge-binder ukuba ifakwe uthotho lweenkqubo ezintsonkothileyo ezinje ngokucinezela kwe-isostatic eshushu.Xa kuthelekiswa nesinyithi esinesantya esiphezulu ngokubhekiselele kobunzima, ubunzima obomvu, ukuxhathisa ukugqoka, njl., kukho ukuphuculwa okukhulu, kodwa iindleko zezixhobo ze-carbide ezifakwe ngesamente nazo zibiza kakhulu kunentsimbi ephezulu.I-Carbide ineenzuzo ezininzi kunezixhobo zangaphambili zesixhobo ngokubhekiselele kubomi besixhobo kunye nesantya sokucubungula.Ekusileni ngokuphindaphindiweyo izixhobo, izixhobo zokugaya iingcali zifunekayo.

2

Indlela yokukhetha i-drill coating

Iingubo zokwaleka zingahlelwa ngokwezi ntlobo zintlanu zilandelayo ngokobubanzi bokusetyenziswa.

Ingagqunywanga:

Iimela ezingagqunywanga zezona zinexabiso eliphantsi kwaye zihlala zisetyenziselwa umatshini wezinto ezithambileyo ezifana neealloyi zealuminiyam kunye nentsimbi ethambileyo.

Ukwaleka kweoksidi emnyama:

Iingubo ezixutywe nge-oxidized ziyakwazi ukubonelela nge-lubricity engcono kunezixhobo ezingagqunywanga, kwaye zingcono ngokubhekiselele kwi-oxidation kunye nokumelana nobushushu, kwaye kunokunyusa ubomi benkonzo ngaphezu kwe-50%.

Ukugquma kwe-Titanium nitride:

I-Titanium nitride yeyona nto ixhaphakileyo yokugquma kwaye ayifanelekanga ukusetyenzwa kwezixhobo ezinobunzima obuphezulu kunye nobushushu obuphezulu bokusebenza.

Ukugquma kwe-Titanium carbonitride:

I-Titanium carbonitride iphuhliswa kwi-titanium nitride kwaye inobushushu obuphezulu kunye nokumelana nokunxiba, ngokuqhelekileyo imfusa okanye eluhlaza okwesibhakabhaka.Isetyenziselwa ukwenza izixhobo zokusebenza zentsimbi kwindawo yokusebenzela ye-Haas.

IAluminiyam yeNitride yeTitanium yoMgqumo:

I-Aluminium titanium nitride ixhathisa kakhulu kumaqondo okushisa aphezulu kunazo zonke iingubo ezingentla, ngoko ingasetyenziselwa kwiindawo eziphezulu zokusika.Umzekelo, ukusetyenzwa kwe-superalloys.Ikwafanelekile ukucutshungulwa kwentsimbi kunye nensimbi engenasici, kodwa ngenxa yezinto eziqukethe i-aluminium, ukuphendulwa kweekhemikhali kuya kwenzeka xa kusetyenzwa i-aluminium, ngoko ugweme ukusetyenzwa kwezixhobo eziqukethe i-aluminium.

3

Drill bit geometry

Iimpawu zejometri zinokwahlulwa zibe ngamacandelo amathathu alandelayo:

Ubude

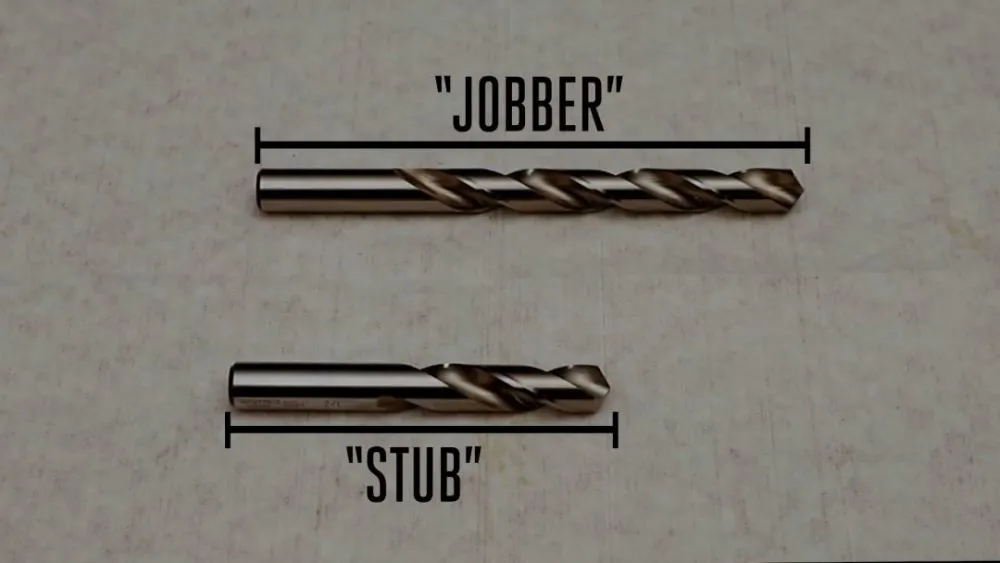

Umlinganiselo wobude ukuya kwi-diameter ubizwa ngokuba yi-diameter ephindwe kabini, kwaye encinci i-diameter ephindwe kabini, ngcono ukuqina.Ukukhetha i-drill kunye nobude bomphetho ukwenzela nje ukususwa kwe-chip kunye nobude obufutshane obugqithisiweyo kunokuphucula ukuqina ngexesha lomatshini, ngaloo ndlela ukwandisa ubomi benkonzo yesixhobo.Ubude be-blade obungonelanga bunokonakalisa i-drill.

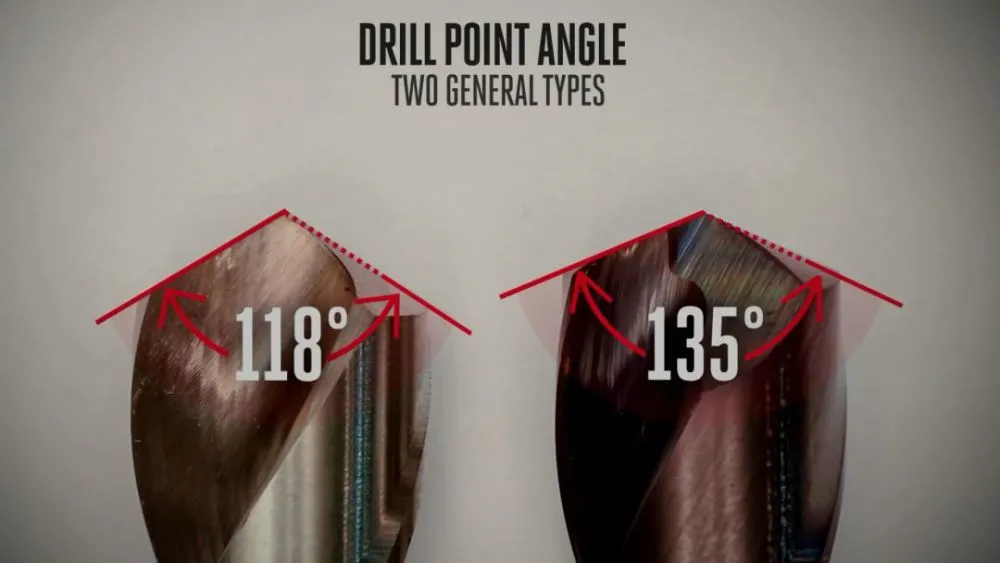

I-angle yencam yokubhola

I-angle yencam ye-drill ye-118° yeyona nto ixhaphakileyo kumatshini kwaye isoloko isetyenziselwa iintsimbi ezithambileyo njengentsimbi ethambileyo kunye ne-aluminiyam.Uyilo lwale engile ngokuqhelekileyo aluzicingeli, nto leyo ethetha ukuba akunakuphepheka ukutshiza umngxuma ophakathi kuqala.I-engile yencam ye-135 ° idla ngokuba nomsebenzi wokuzimela.Ekubeni akukho mfuneko yokutshiza umngxuma wokubeka iziko, oku kuya kwenza ukuba kungadingeki ukuba ubhobhoze umngxuma ophakathi ngokwahlukileyo, ngaloo ndlela ulondoloze ixesha elininzi.

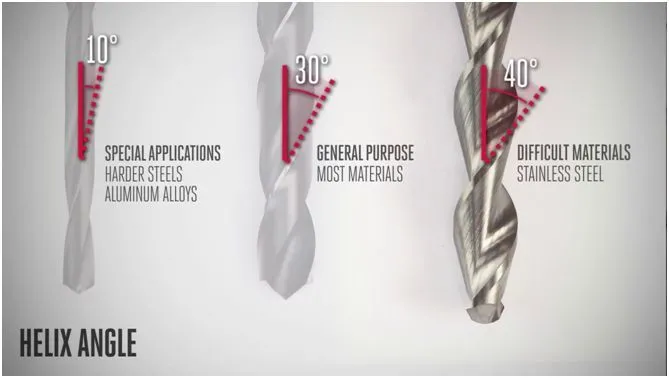

I-engile ye-Helix

I-angle ye-helix ye-30 ° yinto efanelekileyo yokukhetha izinto ezininzi.Kodwa kwiindawo ezifuna ukukhutshwa okungcono kwe-chip kunye nomphetho oqinileyo wokusika, i-drill ene-angle encinci ye-helix inokukhethwa.Kwizinto ezinzima kumatshini ezifana nentsimbi engenasici, uyilo olune-angle enkulu ye-helix inokukhethwa ukuhambisa i-torque.

Ixesha lokuposa: Jun-02-2022