Niaj hnub no, kuv yuav qhia yuav ua li cas xaiv ib tug xyaum me ntsis los ntawm peb lub hauv paus tej yam kev mob ntawm lubxyaum me ntsis, uas yog: khoom, txheej thiab geometric yam ntxwv.

1

Yuav ua li cas xaiv cov khoom ntawm lub laum

Cov ntaub ntawv tuaj yeem muab faib ua peb hom: high-speed steel, cobalt-muaj cov hlau ceev ceev thiab cov khoom carbide.

High-speed steel yog tam sim no feem ntau siv dav thiab pheej yig tshaj cov cuab yeej txiav.Lub laum me ntsis ntawm high-speed steel yuav siv tau tsis tsuas yog ntawm tes hluav taws xob xyaum, tab sis kuj nyob rau hauv ib puag ncig nrog zoo stability xws li drilling tshuab.Lwm qhov laj thawj rau lub neej ntev ntawm kev kub ceev steel tej zaum yuav yog lub cuab yeej ua los ntawm cov hlau kub ceev tuaj yeem rov ua dua hauv av.Vim nws tus nqi qis, nws tsis yog tsuas yog siv rau kev sib tsoo rau hauv cov khoom laum, tab sis kuj siv dav hauv cov cuab yeej tig.

Cobalt High Speed Steel (HSSCO):

Cobalt-muaj cov high-speed steel muaj zoo hardness thiab liab hardness tshaj high-ceev steel, thiab qhov nce nyob rau hauv hardness kuj txhim kho nws cov hnav tsis kam, tab sis tib lub sij hawm txi ib feem ntawm nws toughness.Ib yam li cov hlau kub ceev: lawv tuaj yeem siv los txhim kho cov sij hawm los ntawm kev sib tsoo.

Carbide (CARBIDE):

Cemented carbide yog cov khoom siv hlau ua cov khoom sib xyaw.Ntawm lawv, tungsten carbide yog siv los ua cov matrix, thiab qee cov ntaub ntawv ntawm lwm cov ntaub ntawv siv los ua cov ntawv khi kom tau sintered los ntawm cov txheej txheem nyuaj xws li kub isostatic nias.Piv nrog rau high-ceev steel nyob rau hauv cov nqe lus ntawm hardness, liab hardness, hnav tsis kam, thiab lwm yam, muaj ib tug loj kev txhim kho, tab sis tus nqi ntawm cov cemented carbide cov cuab yeej kuj kim kim tshaj li high-speed steel.Carbide muaj qhov zoo dua li cov khoom siv yav dhau los ntawm cov cuab yeej siv lub neej thiab kev ua haujlwm ceev.Hauv kev sib tsoo cov cuab yeej rov ua dua, cov cuab yeej sib tsoo yuav tsum tau ua.

2

Yuav ua li cas xaiv lub laum txheej

Cov txheej txheem tuaj yeem raug faib ua tsib hom hauv qab no raws li qhov kev siv.

Uncoated:

Cov riam uas tsis muaj coated yog cov pheej yig tshaj plaws thiab feem ntau yog siv los ua cov ntaub ntawv softer xws li txhuas alloys thiab cov hlau me me.

Dub oxide txheej:

Oxidized coatings tuaj yeem muab lubricity zoo dua li cov cuab yeej tsis muaj coated, thiab tseem zoo dua ntawm oxidation thiab kub tsis kam, thiab tuaj yeem ua rau lub neej ua haujlwm ntau dua 50%.

Titanium nitride txheej:

Titanium nitride yog cov txheej txheem ntau tshaj plaws thiab tsis haum rau kev ua cov ntaub ntawv nrog cov hardness siab thiab ua haujlwm kub.

Titanium carbonitride txheej:

Titanium carbonitride yog tsim los ntawm titanium nitride thiab muaj qhov kub thiab txias thiab hnav tsis kam, feem ntau yog xim liab lossis xiav.Siv los tshuab cam khwb cia hlau workpieces hauv Haas rhiav.

Aluminium Nitride Titanium Txheej:

Aluminium titanium nitride tiv taus kub ntau dua li cov txheej txheem saum toj no, yog li nws tuaj yeem siv rau hauv qhov chaw txiav siab dua.Piv txwv li, ua superalloys.Nws kuj tseem tsim nyog rau kev ua cov hlau thiab cov hlau tsis muaj steel, tab sis vim yog cov khoom muaj txhuas, cov tshuaj tiv thaiv yuav tshwm sim thaum ua cov txhuas, yog li tsis txhob ua cov khoom siv txhuas.

3

Laum me ntsis geometry

Geometric nta tuaj yeem muab faib ua 3 ntu hauv qab no:

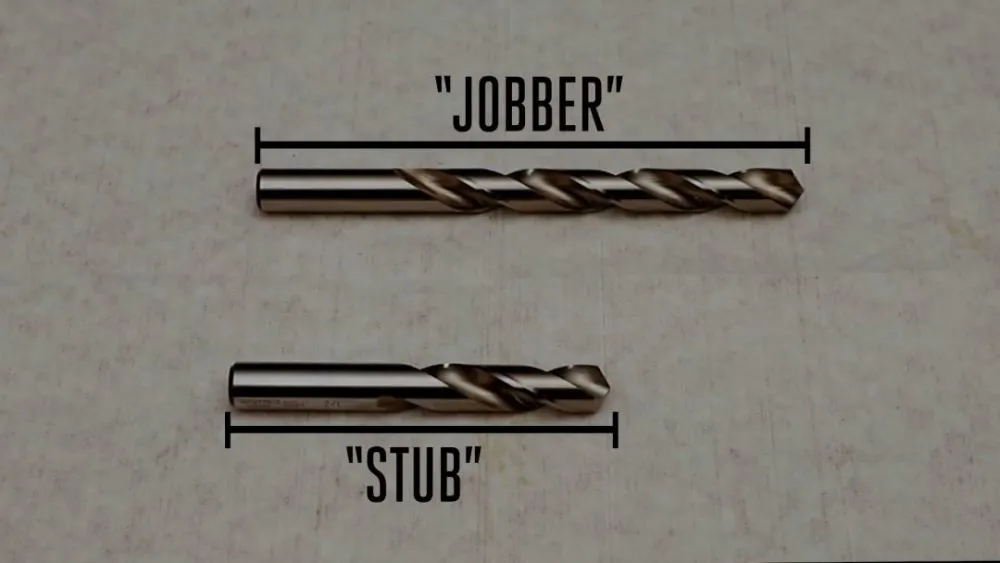

Ntev

Qhov piv ntawm qhov ntev mus rau txoj kab uas hla yog hu ua ob txoj kab uas hla, thiab qhov me me ntawm ob txoj kab uas hla, qhov zoo dua qhov rigidity.Xaiv ib lub laum nrog lub ntug ntev tsuas yog rau kev tshem tawm cov nti thiab qhov luv luv overhang ntev tuaj yeem txhim kho qhov nruj thaum lub sijhawm machining, yog li ua rau kev pabcuam lub neej ntawm cov cuab yeej.Tsis txaus hniav ntev yuav ua rau lub laum puas.

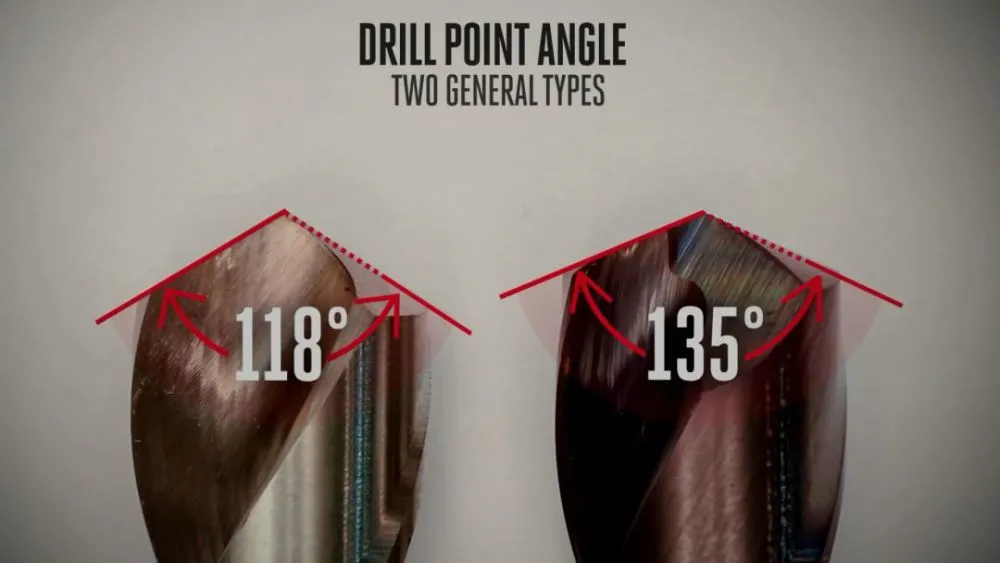

Drill lub kaum sab xis

Lub kaum sab xis ntawm lub kaum sab xis ntawm 118 ° yog qhov feem ntau siv hauv machining thiab feem ntau yog siv rau cov hlau mos xws li cov hlau me me thiab txhuas.Tus tsim ntawm lub kaum sab xis no feem ntau tsis yog tus kheej-center, uas txhais tau hais tias nws yog ib qho inevitable rau tshuab lub centering qhov ua ntej.Lub kaum sab xis 135 ° laum lub kaum sab xis feem ntau muaj qhov ua haujlwm ntawm tus kheej.Txij li thaum tsis tas yuav tshuab lub qhov nruab nrab, qhov no yuav ua rau nws tsis tsim nyog los laum lub qhov nruab nrab ntawm qhov sib cais, yog li txuag sijhawm ntau.

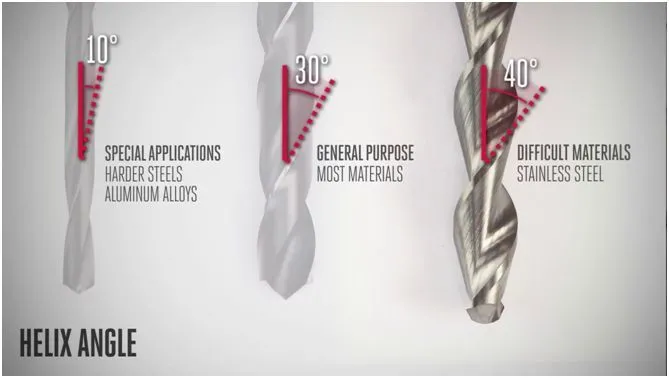

Helix lub kaum sab xis

Lub kaum sab xis ntawm 30 ° yog qhov kev xaiv zoo rau cov khoom siv feem ntau.Tab sis rau ib puag ncig uas xav tau kev tshem tawm cov nti zoo dua thiab muaj zog txiav ntug, ib qho kev xyaum nrog lub kaum sab xis me me tuaj yeem xaiv.Rau cov ntaub ntawv nyuaj-rau-tshuab xws li cov hlau tsis muaj steel, tus qauv tsim nrog lub kaum sab xis loj tuaj yeem raug xaiv los xa cov torque.

Post lub sij hawm: Jun-02-2022