A yau, zan raba yadda za a zabi wani rawar soja bit ta uku asali yanayi narawar jiki, waxanda suke: abu, sutura da halayen geometric.

1

Yadda za a zabi kayan aikin rawar soja

Za'a iya raba kayan kusan zuwa nau'ikan nau'ikan uku: ƙarfe mai sauri, cobalt mai ƙunshe da ƙarfe mai sauri da ƙarfi.

Karfe mai sauri a halin yanzu shine mafi yawan amfani da kayan aikin yankan mafi arha.Za'a iya amfani da ƙwanƙwasa na ƙarfe mai sauri ba kawai a kan na'urorin lantarki na hannu ba, har ma a cikin yanayin da ke da kwanciyar hankali kamar na'urorin hakowa.Wani dalili na tsawon tsayin ƙarfe mai sauri na iya zama cewa kayan aikin da aka yi da karfe mai sauri za a iya maimaita ƙasa akai-akai.Saboda ƙarancin farashinsa, ba wai kawai ana amfani da shi don niƙa cikin raƙuman ruwa ba, har ma ana amfani da shi sosai wajen juya kayan aikin.

Ƙarfe Mai Saurin Ƙarfe (HSSCO):

Karfe mai saurin gaske mai dauke da sinadarin Cobalt yana da taurinsa da ja fiye da karfe mai sauri, haka nan kuma karuwar taurin yana inganta juriyar sa, amma a lokaci guda yana sadaukar da wani bangare na taurinsa.Daidai da ƙarfe mai sauri: ana iya amfani da su don inganta yawan lokuta ta hanyar niƙa.

Carbide (carbide):

Carbide da aka yi da siminti abu ne mai haɗaka da ƙarfe.Daga cikin su, ana amfani da tungsten carbide a matsayin matrix, kuma ana amfani da wasu kayan wasu kayan azaman abin ɗaure da za a yi amfani da su ta hanyar jerin hadaddun matakai kamar matsananciyar isostatic.Idan aka kwatanta da ƙarfe mai sauri ta fuskar taurin, ja, juriya, da dai sauransu, ana samun ci gaba mai yawa, amma farashin kayan aikin carbide na siminti shima ya fi tsada fiye da ƙarfe mai sauri.Carbide yana da fa'idodi fiye da kayan aikin da suka gabata dangane da rayuwar kayan aiki da saurin sarrafawa.A cikin maimaita niƙa na kayan aiki, ana buƙatar kayan aikin niƙa ƙwararrun.

2

Yadda za a zabi suturar rawar soja

Za a iya rarraba suturar da aka yi wajen zuwa nau'ikan iri biyar masu zuwa gwargwadon girman amfani.

Mara rufi:

Wukake marasa rufi sune mafi arha kuma galibi ana amfani da su don injin kayan laushi irin su alloys na aluminum da ƙaramin ƙarfe.

Black oxide shafi:

Abubuwan da aka yi amfani da su na Oxidized na iya samar da mafi kyawun lubricity fiye da kayan aikin da ba a rufe su ba, kuma sun fi kyau a cikin yanayin oxidation da juriya na zafi, kuma suna iya ƙara rayuwar sabis fiye da 50%.

Titanium nitride shafi:

Titanium nitride shine kayan shafa na yau da kullun kuma bai dace da kayan sarrafawa tare da ƙarancin ƙarfi da zafin jiki mai girma ba.

Titanium carbonitride shafi:

Titanium carbonitride an ƙera shi ne daga titanium nitride kuma yana da babban zafin jiki da juriya, yawanci shuɗi ko shuɗi.An yi amfani da shi don yin aikin simintin ƙarfe a cikin aikin Haas.

Aluminum Nitride Titanium Rufin:

Aluminum titanium nitride ya fi tsayayya da yanayin zafi fiye da duk abubuwan da ke sama, don haka ana iya amfani da shi a cikin mafi girman yanki.Misali, sarrafa superalloys.Hakanan ya dace da sarrafa ƙarfe da bakin karfe, amma saboda abubuwan da ke ɗauke da aluminum, halayen sinadarai zasu faru yayin sarrafa aluminum, don haka a guji sarrafa kayan da ke ɗauke da aluminum.

3

Drill bit geometry

Za a iya raba fasalulluka na geometric zuwa sassa 3 masu zuwa:

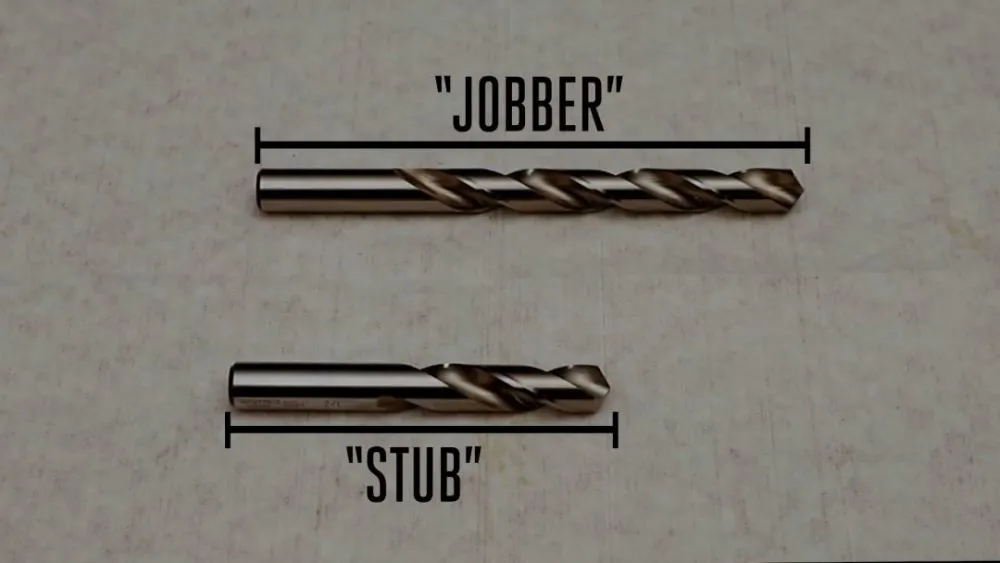

Tsawon

Matsakaicin tsayi zuwa diamita ana kiransa diamita biyu, kuma ƙaramin diamita biyu, mafi kyawun rigidity.Zaɓin rawar soja tare da tsayin gefen kawai don cire guntu da ɗan gajeren tsayin tsayin daka zai iya inganta tsattsauran ra'ayi a lokacin machining, don haka ƙara rayuwar sabis na kayan aiki.Rashin isasshen tsayin ruwa yana iya lalata rawar sojan.

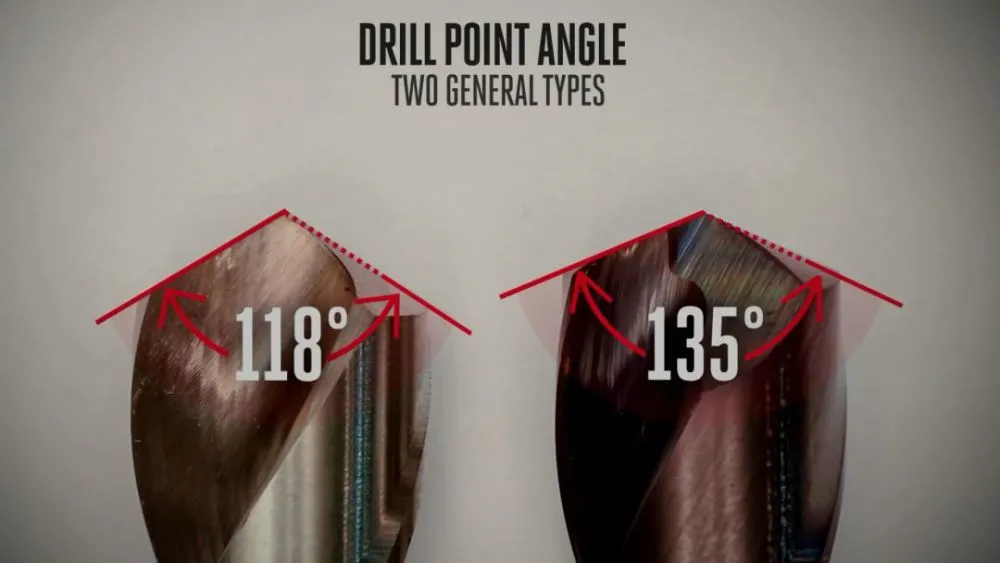

Kusurwar tip

Madaidaicin tip na 118° mai yiwuwa shine ya fi kowa a cikin injina kuma galibi ana amfani dashi don karafa masu laushi kamar ƙarfe mai laushi da aluminum.Zane na wannan kusurwa yawanci ba mai son kai bane, wanda ke nufin cewa ba makawa ne a fara injin rami mai tsakiya.Matsakaicin 135° tip tip ƙwanƙwasa yawanci yana da aikin kai-tsaye.Tun da babu buƙatar injin rami na tsakiya, wannan zai sa ya zama ba dole ba ne a haƙa ramin tsakiya daban, don haka adana lokaci mai yawa.

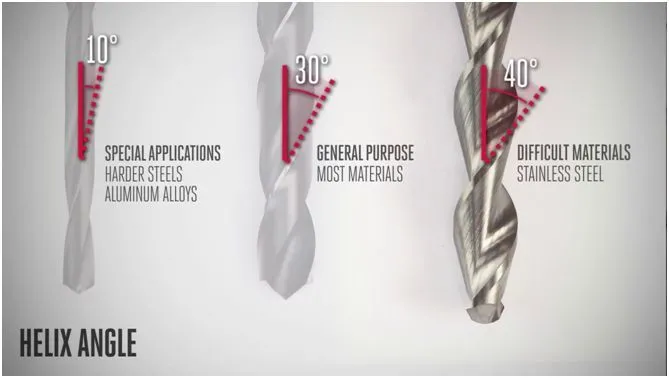

kusurwar Helix

A kusurwar helix na 30 ° shine kyakkyawan zabi ga yawancin kayan.Amma don yanayin da ke buƙatar mafi kyawun ƙaurawar guntu da kuma yanke yanki mai ƙarfi, ana iya zaɓin rawar soja tare da ƙaramin kusurwar helix.Don kayan aiki masu wahala irin su bakin karfe, za'a iya zaɓar zane tare da babban kusurwar helix don watsa juzu'i.

Lokacin aikawa: Juni-02-2022