A yau, zan raba yadda ake zaɓar injin haƙa rami ta cikin manyan sharuɗɗa guda uku nabit ɗin haƙa rami, waɗanda sune: kayan aiki, shafi da halayen geometric.

1

Yadda ake zaɓar kayan aikin rawar soja

Ana iya raba kayan aiki zuwa nau'i uku: ƙarfe mai sauri, ƙarfe mai saurin girma wanda ke ɗauke da cobalt da kuma carbide mai ƙarfi.

Karfe mai sauri a yanzu shine kayan aikin yankewa mafi amfani kuma mafi arha. Ana iya amfani da ɓangaren haƙa ƙarfe mai sauri ba kawai a kan haƙan lantarki na hannu ba, har ma a cikin yanayi mai ingantaccen kwanciyar hankali kamar injin haƙa. Wani dalili kuma na tsawon rai na ƙarfe mai sauri shine cewa kayan aikin da aka yi da ƙarfe mai sauri ana iya niƙa su akai-akai. Saboda ƙarancin farashinsa, ba wai kawai ana amfani da shi don niƙawa zuwa guntun haƙa ba, har ma ana amfani da shi sosai a cikin kayan aikin juyawa.

Karfe Mai Sauri Na Cobalt (HSSCO):

Karfe mai saurin gudu mai ɗauke da cobalt yana da tauri da ja fiye da ƙarfe mai saurin gudu, kuma ƙaruwar tauri kuma yana inganta juriyar sawa, amma a lokaci guda yana ladabtar da wani ɓangare na taurinsa. Kamar ƙarfe mai saurin gudu: ana iya amfani da su don inganta adadin sau ta hanyar niƙa.

Carbide (CARBIDE):

Carbide mai siminti abu ne da aka yi da ƙarfe. Daga cikinsu, ana amfani da tungsten carbide a matsayin matrix, kuma ana amfani da wasu kayan wasu kayan a matsayin abin ɗaurewa don a yi masa siminti ta hanyar jerin ayyuka masu rikitarwa kamar matsewa mai zafi na isostatic. Idan aka kwatanta da ƙarfe mai sauri dangane da tauri, tauri ja, juriyar lalacewa, da sauransu, akwai babban ci gaba, amma farashin kayan aikin carbide mai siminti shi ma ya fi tsada fiye da ƙarfe mai sauri. Carbide yana da fa'idodi fiye da kayan aikin da suka gabata dangane da rayuwar kayan aiki da saurin sarrafawa. A cikin niƙa kayan aiki akai-akai, ana buƙatar kayan aikin niƙa ƙwararru.

2

Yadda ake zaɓar murfin haƙa rami

Za a iya rarraba murfin zuwa nau'ikan guda biyar masu zuwa gwargwadon iyawar amfani.

Ba a rufe ba:

Wukake marasa rufi sune mafi arha kuma galibi ana amfani da su don kera kayan da suka yi laushi kamar ƙarfe na aluminum da ƙarfe mai laushi.

Rufin oxide mai duhu:

Rufin da aka yi da oxidized zai iya samar da man shafawa mai kyau fiye da kayan aikin da ba a rufe ba, kuma ya fi kyau dangane da oxidation da juriya ga zafi, kuma yana iya ƙara tsawon rayuwar sabis da fiye da 50%.

Rufin Titanium nitride:

Titanium nitride shine kayan shafa da aka fi amfani da su kuma bai dace da kayan sarrafa kayan da ke da tauri mai yawa da zafin aiki mai yawa ba.

Rufin carbonitride na titanium:

Ana samar da titanium carbonitride daga titanium nitride kuma yana da juriya mai zafi da kuma lalacewa, yawanci shunayya ko shuɗi. Ana amfani da shi don yin aikin injinan ƙarfe a cikin shagon Haas.

Rufin Titanium na Aluminum Nitride:

Aluminum titanium nitride ya fi juriya ga yanayin zafi mai yawa fiye da duk wani shafi da ke sama, don haka ana iya amfani da shi a cikin yanayi mafi girma na yankewa. Misali, sarrafa superalloys. Hakanan ya dace da sarrafa ƙarfe da bakin ƙarfe, amma saboda abubuwan da ke ɗauke da aluminum, halayen sinadarai za su faru lokacin sarrafa aluminum, don haka a guji sarrafa kayan da ke ɗauke da aluminum.

3

Tsarin yanayin haƙa rami

Za a iya raba siffofin geometric zuwa sassa uku masu zuwa:

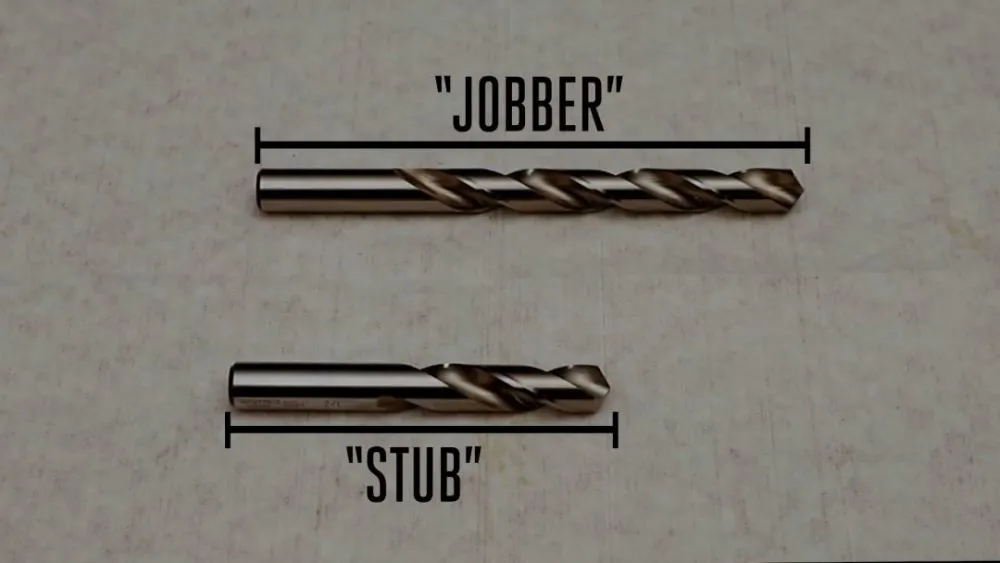

Tsawon

Ana kiran rabon tsayi da diamita mai diamita biyu, kuma ƙaramin diamita mai biyu, mafi kyawun tauri. Zaɓin rami mai tsawon gefen kawai don cire guntu da gajeren tsawon da aka yi sama da shi na iya inganta tauri yayin aikin injin, ta haka yana ƙara tsawon aikin kayan aikin. Rashin isasshen tsawon ruwan wukake yana iya lalata injin.

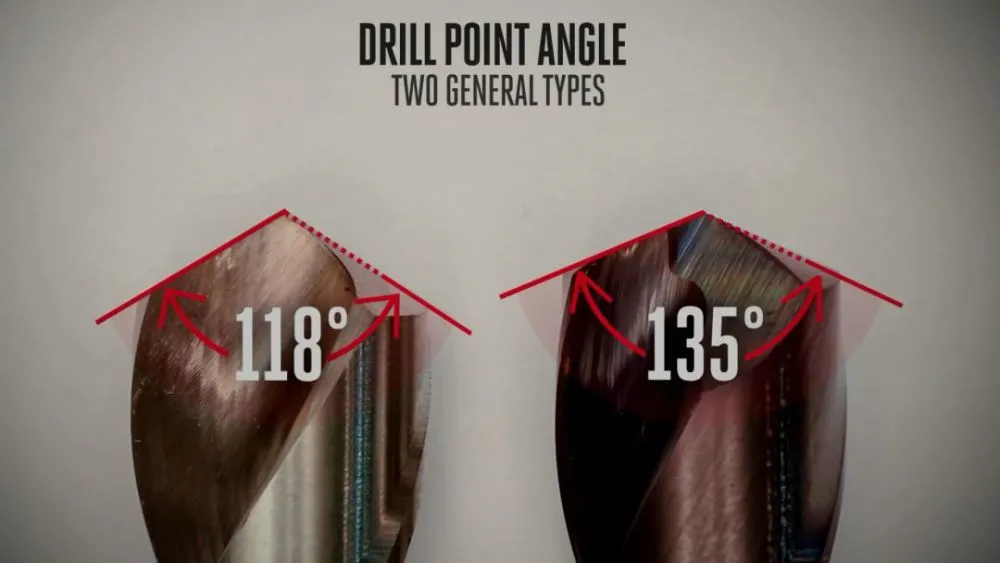

Kusurwar gefen haƙa rami

Kusurwar gefen haƙa rami mai girman 118° wataƙila ita ce mafi yawan amfani a cikin injinan kuma galibi ana amfani da ita ga ƙarfe masu laushi kamar ƙarfe mai laushi da aluminum. Tsarin wannan kusurwar yawanci ba ta mai da hankali kan kanta ba, wanda ke nufin cewa ba makawa ne a fara haƙa ramin tsakiya. Kusurwar gefen haƙa rami mai girman 135° yawanci tana da aikin mai da hankali kan kanta. Tunda babu buƙatar haƙa ramin tsakiya, wannan zai sa ya zama dole a haƙa ramin tsakiya daban, don haka yana adana lokaci mai yawa.

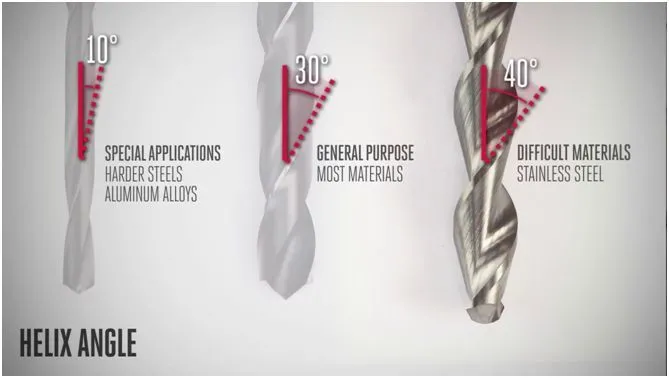

Kusurwar helix

Kusurwar helix mai digiri 30 a tsayin digiri 30 kyakkyawan zaɓi ne ga yawancin kayan aiki. Amma ga muhallin da ke buƙatar ingantaccen cire guntu da kuma ingantaccen gefen yankewa, ana iya zaɓar wani rami mai ƙaramin kusurwar helix. Don kayan da ke da wahalar amfani da su kamar bakin ƙarfe, ana iya zaɓar ƙira mai babban kusurwar helix don watsa ƙarfin juyi.

Lokacin Saƙo: Yuni-02-2022