1, Inkqubo yokhetho lwabasiki bokungqusha bajonga le miba ilandelayo ukukhethayo:

(1) Imilo yenxalenye (ukuqwalasela iprofayili yokucubungula): Iprofayili yokucubungula ngokubanzi ingaba caba, inzulu, i-cavity, intambo, njl.Umzekelo, i-fillet milling cutter inokusila imiphezulu yeconvex, kodwa hayi imiphezulu yeMilling concave.

(2) Material: Qwalasela machinability yayo, chip ukwenza, ukuqina kunye alloying element.Abavelisi bezixhobo ngokubanzi bohlula izixhobo zibe yintsimbi, intsimbi engatyiwa, intsimbi etyhidiweyo, isinyithi esingeyontsimbi, iialloyi ezinkulu, iialloyi zetitanium kunye nezinto eziqinileyo.

(3) Iimeko zokutshiza: Iimeko zokutshiza ziquka ukuzinza kwenkqubo ye-workpiece yesixhobo somatshini, i-clamping imeko yomnini wesixhobo kunye nokunye.

(4) Uzinzo lwenkqubo yomatshini wokulungisa isixhobo somatshini: Oku kufuna ukuqonda amandla akhoyo esixhobo somatshini, uhlobo lwe-spindle kunye neenkcukacha, ubudala besixhobo somatshini, njl. radial runout Imeko.

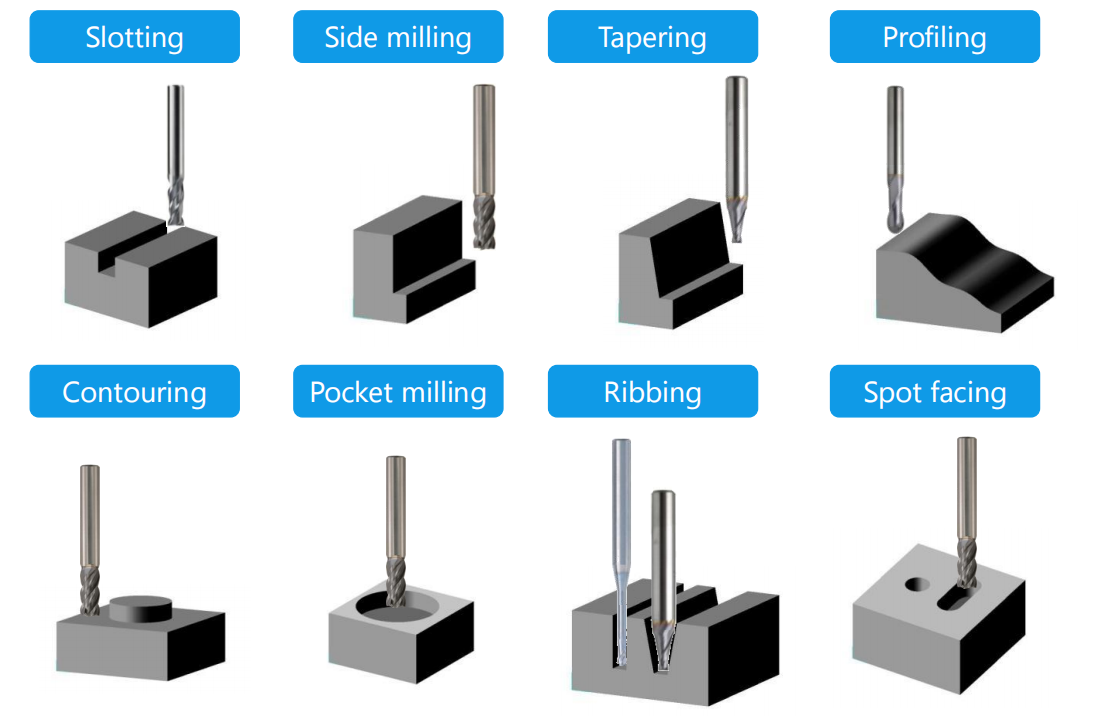

(4) Udidi lokucubungula kunye noluhlu olungaphantsi: Oku kubandakanya ukugaya amagxa, ukugaya inqwelomoya, ukugaya iprofayili, njl., ekufuneka zidityaniswe neempawu zesixhobo sokukhethwa kwesixhobo.

2. Ukukhethwa kwe-engile yejometri ye-milling cutter

(1)Ukhetho lwe-engile yangaphambili.I-rake angle ye-milling cutter kufuneka imiselwe ngokwezinto zesixhobo kunye nomsebenzi.Kukho rhoqo iimpembelelo ekugayeni, ngoko ke kuyimfuneko ukuqinisekisa ukuba i-edge yokusika inamandla aphezulu.Ngokubanzi, i-engile yeraki ye-engile yokusila incinci kune-engile yokusika yesixhobo sokujika;isinyithi esinesantya esiphezulu sikhulu kunesixhobo se-carbide esine-cemented;Ukongeza, xa ukugaya izinto zeplastiki, ngenxa ye-deformation enkulu yokusika, kufuneka kusetyenziswe i-angle enkulu yeraki;xa milling brittle materials , I-engile yeharibi kufuneka ibe ncinane;xa kusetyenzwa izixhobo ezinamandla aphezulu kunye nobunzima, i-engile ye-rake engalunganga ingasetyenziswa.

(2)Ukhetho lotyekelo lwencakuba.I-engile ye-helix β yesangqa sangaphandle somgca wesiphelo kunye ne-cylindrical milling cutter yi-blade inclination λ s.Oku kwenza ukuba amazinyo okusika akwazi ukusika ngokuthe ngcembe ngaphakathi nangaphandle kwendawo yokusebenza, ukuphucula ukuguda kokusila.Ukwandisa i-β kunokonyusa i-engile yerake yokwenyani, lola i-edge yokusika, kwaye wenze iitshiphusi zibe lula ukuzikhupha.Kubasiki bokungqusha abanobubanzi obumxinwa bokusila, ukunyusa i-engile ye-helix β akubalulekanga kancinci, ngoko ke β=0 okanye ixabiso elincinane lithathwa ngokubanzi.

(3)Ukhetho lwe-angle yokuphambuka ephambili kunye ne-engile yesibini yokuphambuka.Impembelelo ye-angle yokungena ye-face milling cutter kunye nefuthe layo kwinkqubo yokugaya ifana ne-angle yokungena yesixhobo sokujika ekujikeni.Ii-engile zokungena ezisetyenziswa ngokuqhelekileyo yi-45°, 60°, 75°, kunye ne-90°.Ukuqina kwenkqubo yenkqubo kulungile, kwaye ixabiso elincinci lisetyenziswa;ngaphandle koko, ixabiso elikhulu lisetyenzisiweyo, kunye nokukhethwa kwe-angle yokungena kuboniswe kwiThebhile 4-3.I-engile yesibini yokuphambuka gabalala yi-5°~10°.I-cylindrical milling cutter inomgca oyintloko wokusika kwaye akukho nxalenye yesibini yokusika, ngoko akukho nqanaba lesibini le-deflection angle, kwaye i-angle yokungena yi-90 °.

Ixesha lokuposa: Aug-24-2021