1, Inkqubo yokukhetha abasiki bokusika ngokubanzi iqwalasela ezi zinto zilandelayo ekufuneka zikhethwe:

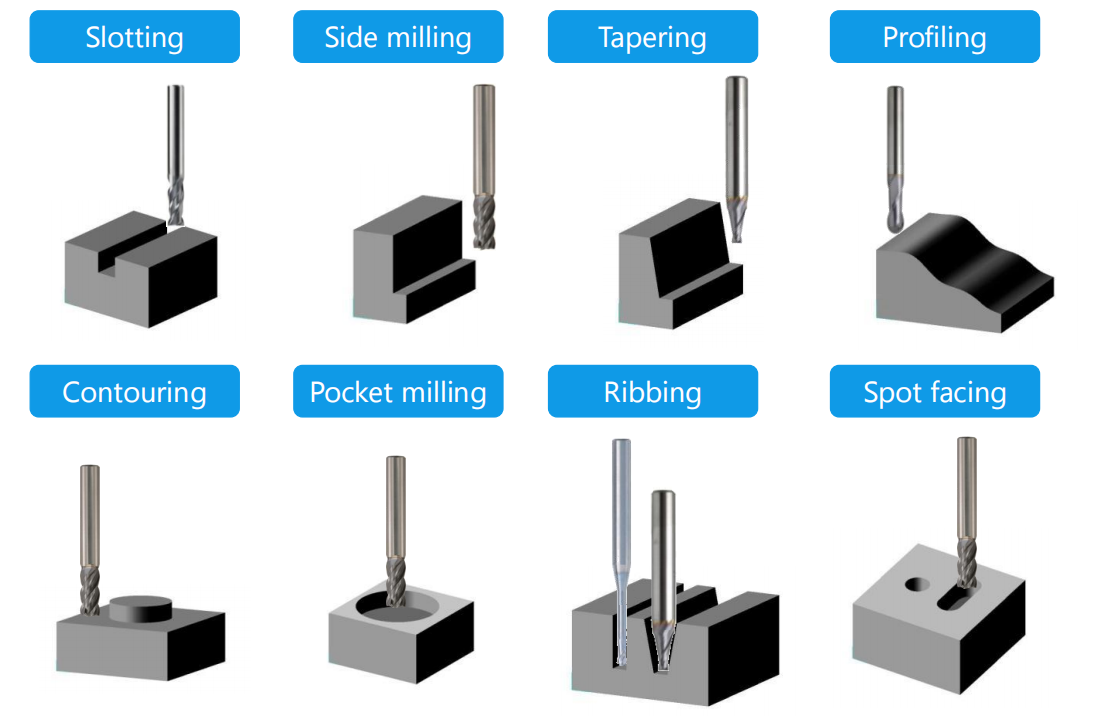

(1) Imilo yenxalenye (ukuqwalasela iprofayili yokucubungula): Iprofayili yokucubungula ngokubanzi ingaba tyaba, inzulu, ingaphakathi, intambo, njl. Izixhobo ezisetyenziselwa iiprofayili zokucubungula ezahlukeneyo zahlukile. Umzekelo, umsiki we-fillet milling unokugaya iindawo ezixineneyo, kodwa kungekhona iindawo ezixineneyo zokugaya.

(2) Izinto: Cinga ngobuchule bazo bokusebenza, ukwakheka kweetshiphusi, ubulukhuni kunye nezinto zokudibanisa. Abavelisi bezixhobo ngokubanzi bahlulahlula izinto zibe yintsimbi, intsimbi engatyiwayo, isinyithi esityhidiweyo, iintsimbi ezingezizo iintsimbi, ii-super alloys, ii-titanium alloys kunye nezinto eziqinileyo.

(3) Iimeko zoomatshini: Iimeko zoomatshini ziquka uzinzo lwenkqubo yokusebenza yesixhobo somatshini, imeko yokuxinana kwesibambi sesixhobo njalo njalo.

(4) Uzinzo lwenkqubo yesixhobo-isixhobo somatshini-isixhobo somsebenzi: Oku kufuna ukuqonda amandla akhoyo esixhobo somatshini, uhlobo lwe-spindle kunye neenkcukacha, ubudala besixhobo somatshini, njl.njl., kunye nokuphakama okude kwesibambi sesixhobo kunye nemeko yaso yokubaleka kwe-axial/radial.

(4) Udidi lokucubungula kunye nodidi oluphantsi: Oku kuquka ukugawula amagxa, ukugawula ngeplani, ukugawula iprofayili, njl.njl., ekufuneka kudityaniswe neempawu zesixhobo sokukhetha isixhobo.

2. Ukukhethwa kwe-engile yejometri yomsiki wokugaya

(1) Ukukhetha i-engile engaphambili. I-engile yerakhi yomsiki wokugaya kufuneka imiselwe ngokwezinto ezisetyenziswa sisixhobo kunye nomsebenzi. Kudla ngokubakho iimpembelelo ekugayeni, ngoko ke kuyimfuneko ukuqinisekisa ukuba umda wokusika unamandla aphezulu. Ngokubanzi, i-engile yerakhi yomsiki wokugaya incinci kune-engile yerakhi yokusika yesixhobo sokujika; intsimbi ekhawulezayo inkulu kunesixhobo se-carbide esifakwe isamente; ukongeza, xa kugaywa izinto zeplastiki, ngenxa yokuguquguquka okukhulu kokusika, kufuneka kusetyenziswe i-engile enkulu yerakhi; xa kugaywa izinto ezibuthathaka, i-engile yerakhi kufuneka ibe ncinci; xa kusetyenzwa izinto ezinamandla aphezulu kunye nobunzima, i-engile yerakhi engalunganga nayo ingasetyenziswa.

(2) Ukukhetha indlela yokuthambekela kweblade. I-engile ye-helix β yesangqa sangaphandle se-end mill kunye ne-cylindrical milling cutter yi-blade intensity λ s. Oku kwenza amazinyo okusika angakwazi ukunqumla kancinci ngaphakathi nangaphandle kwe-workpiece, nto leyo ephucula ukuguda kwe-milling. Ukwandisa i-β kunokunyusa i-engile ye-rake yokwenyani, kulole umphetho wokusika, kwaye kwenze kube lula ukukhupha ii-chips. Kwi-milling cutters ezinobubanzi obuncinci bokugaya, ukunyusa i-engile ye-helix β akubalulekanga kangako, ngoko ke ixabiso eliphantsi lihlala lithathwa yi-β=0 okanye ixabiso elincinci.

(3)Ukukhethwa kwe-engile yokujika ephambili kunye ne-engile yokujika yesibini. Isiphumo se-engile yokungena yesixhobo sokusika ubuso kunye nempembelelo yaso kwinkqubo yokusika iyafana neye-engile yokungena yesixhobo sokujika ekujikeni. Ii-engile zokungena ezisetyenziswa rhoqo yi-45°, 60°, 75°, kunye ne-90°. Ukuqina kwenkqubo yenkqubo kulungile, kwaye ixabiso elincinci liyasetyenziswa; kungenjalo, ixabiso elikhulu liyasetyenziswa, kwaye ukhetho lwe-engile yokungena luboniswe kwiTheyibhile 4-3. I-engile yokujika yesibini ngokubanzi yi-5°~10°. I-cylindrical milling cutter inomphetho oyintloko kuphela kwaye ayinamphetho wesibini, ngoko ke akukho angle yesibini yokujika, kwaye i-engile yokungena yi-90°.

Ixesha lokuthumela: Agasti-24-2021