High Hardness 4-Flute Inner R Corner Radius End Milling Cutters for Precision Machining

This high-performance CNC internal R-profile milling cutter is equipped with an ultra-fine-grained hard alloy base and advanced AlTiN/DLC coating, ensuring excellent hardness and thermal stability. Its optimized four-edge design, precisely polished cutting edges, and efficient chip-removal groove pattern work together to achieve smooth cutting, excellent surface finish, and long tool life. It is specially designed for applications such as molds, automotive parts, etc., which require high-precision internal corners and high-efficiency semi-finishing and finishing processes.

Important Attributes

| Product Name | Aluminum DLC Internal R Milling Cutter | Brand | MSK |

| Item Number | MSKDT-130 | Coating | DLC coating |

| Applicable Machine Tool | Milling Machine | Machining range | 55°-58° |

| Applicable Materials | Aluminum alloys, copper alloys, etc | Applicable Equipment | CNC machining centers, engraving machines, precision engraving machines, and other high-speed machines. |

| Model NO. | MSKDT-130 |

| Application | Aluminum |

| Customized Support | OEM |

| Packing | Plastic Box |

| Place of Origin | China |

| Suitiable for | Metal |

| Precision | High Precision |

| Surface Finish | DIc |

| Applicable Equipment | CNC Machining Centers, EngravingMachines |

| Transport Package | Plastic Box |

| Trademark | MSK |

| HS Code | 8207400000 |

| Flute Number | 4T |

| Product Name | Dlc Inner R End Mill |

| M0Q | 10PCS |

| Warranty | 3 Months |

| Keywords | Internal R Tool Corner RoundingEnd Mill |

| HRC | 55 |

| Application Environment | Metal |

| Delivery Time | 7-15days |

| Shipment | DHL.TNT.UPS.FedEx. EMS.SfExpress |

| Specification | 4-20mm |

| Origin | Tianjin China |

| Production Capacity | 500 Per Week |

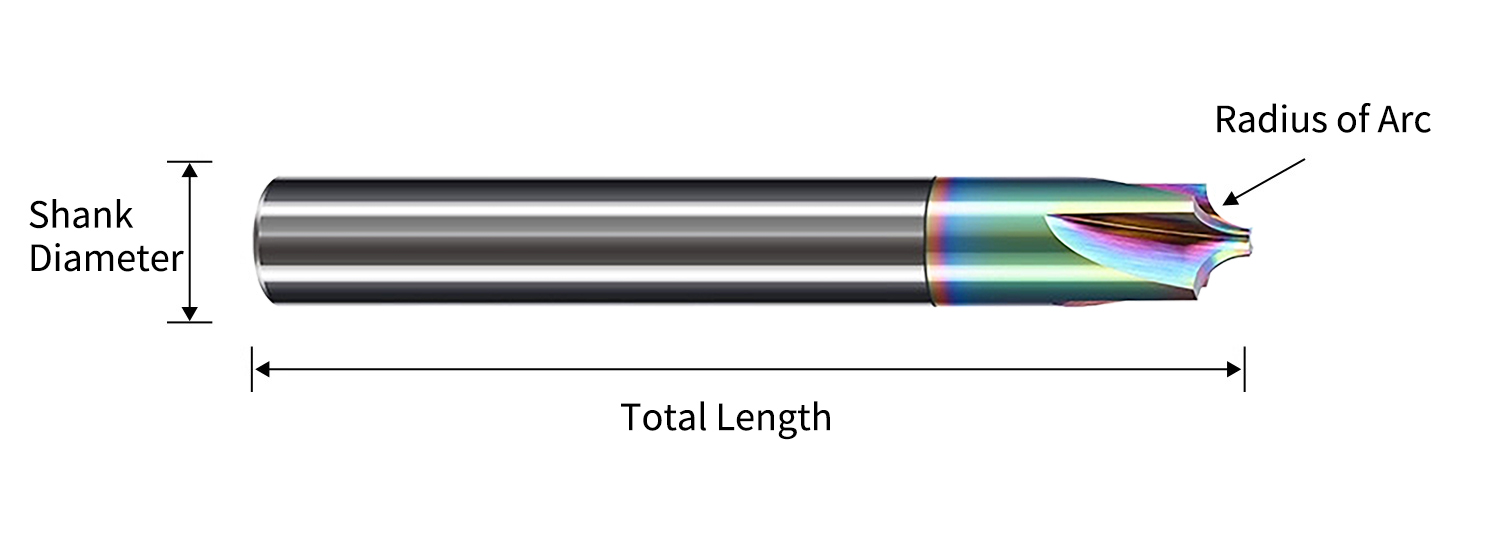

| Flute Diameter | Angle | Total Length | Flutes |

| D4 | R0.2 | 50L | 4T |

| D4 | R0.3 | 50L | 4T |

| D4 | R0.4 | 50L | 4T |

| D4 | R0.5 | 50L | 4T |

| D4 | R0.75 | 50L | 4T |

| D4 | R1.5 | 50L | 4T |

| D6 | R1.5 | 50L | 4T |

| D6 | R2 | 50L | 4T |

| D6 | R2.5 | 50L | 4T |

| D8 | R3 | 60L | 4T |

| D8 | R3.5 | 60L | 4T |

| D10 | R4 | 60L | 4T |

| D12 | R5 | 60L | 4T |

| D14 | R6 | 60L | 4T |

| D16 | R7 | 75L | 4T |

| D20 | R8 | 100L | 4T |

Product Features

One-piece molding, burr-free

High processing efficiency, excellent workpiece surface finish

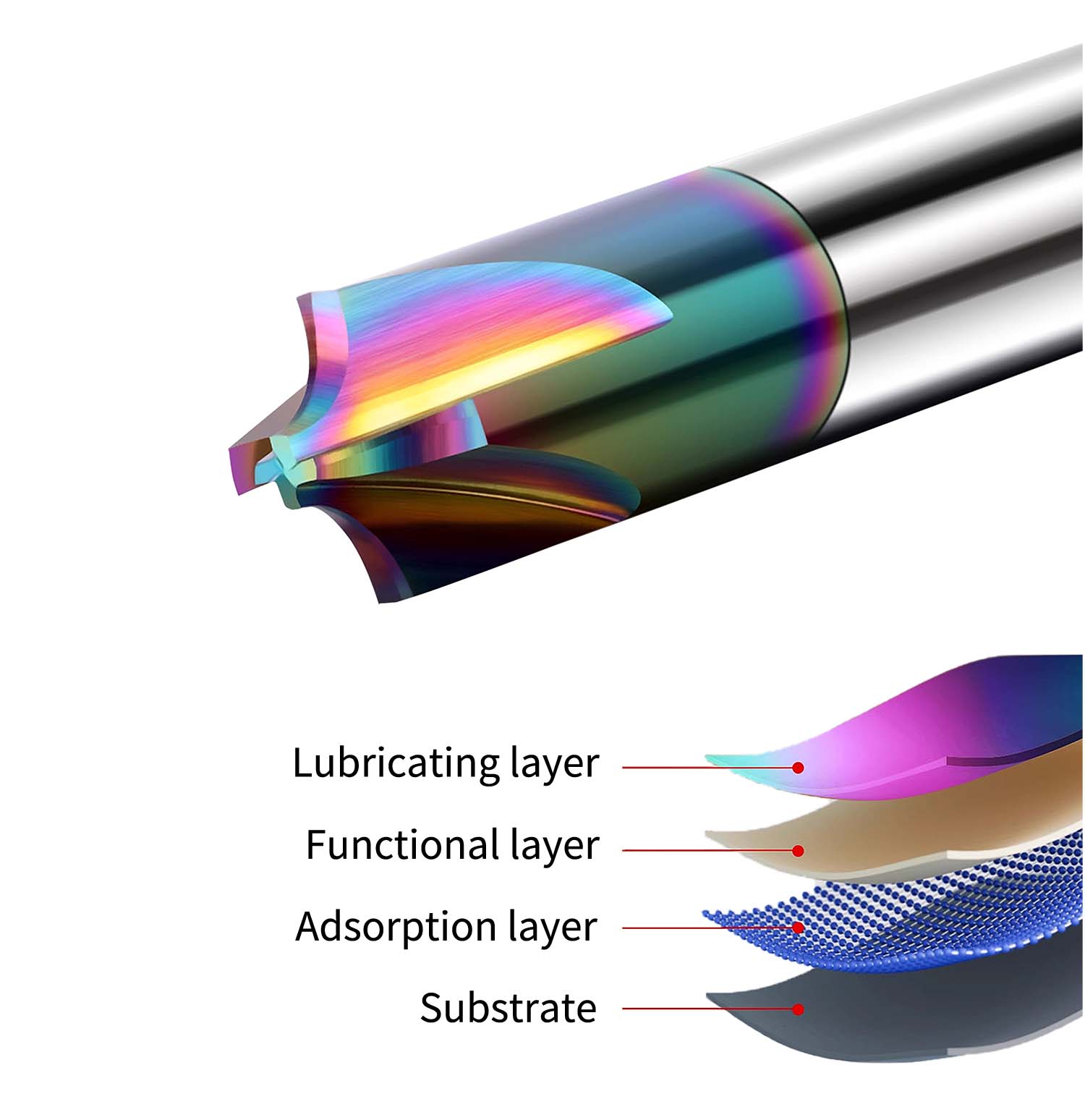

DLC Coating

Upgraded coating enhances wear resistance, ensuring sharp cutting edges without chipping during rapid milling, and providing superior durability.

New edge dulling treatment

Highly efficient chip removal, non-stick cutting

Highly efficient chip removal, non-stick cutting

Advantages

1.Outstanding durability and extremely long lifespan

Top-grade substrate and coating combination: Utilizing ultra-fine grain hard alloy as the base material, it achieves a perfect balance of high strength and impact toughness. Combined with advanced AlTiN or DLC coatings, it endows the cutting tool with extremely high surface hardness, excellent thermal stability and outstanding wear resistance. It effectively prevents crescent groove wear and thermal cracks during high-speed machining, significantly extending the service life of the cutting tool.

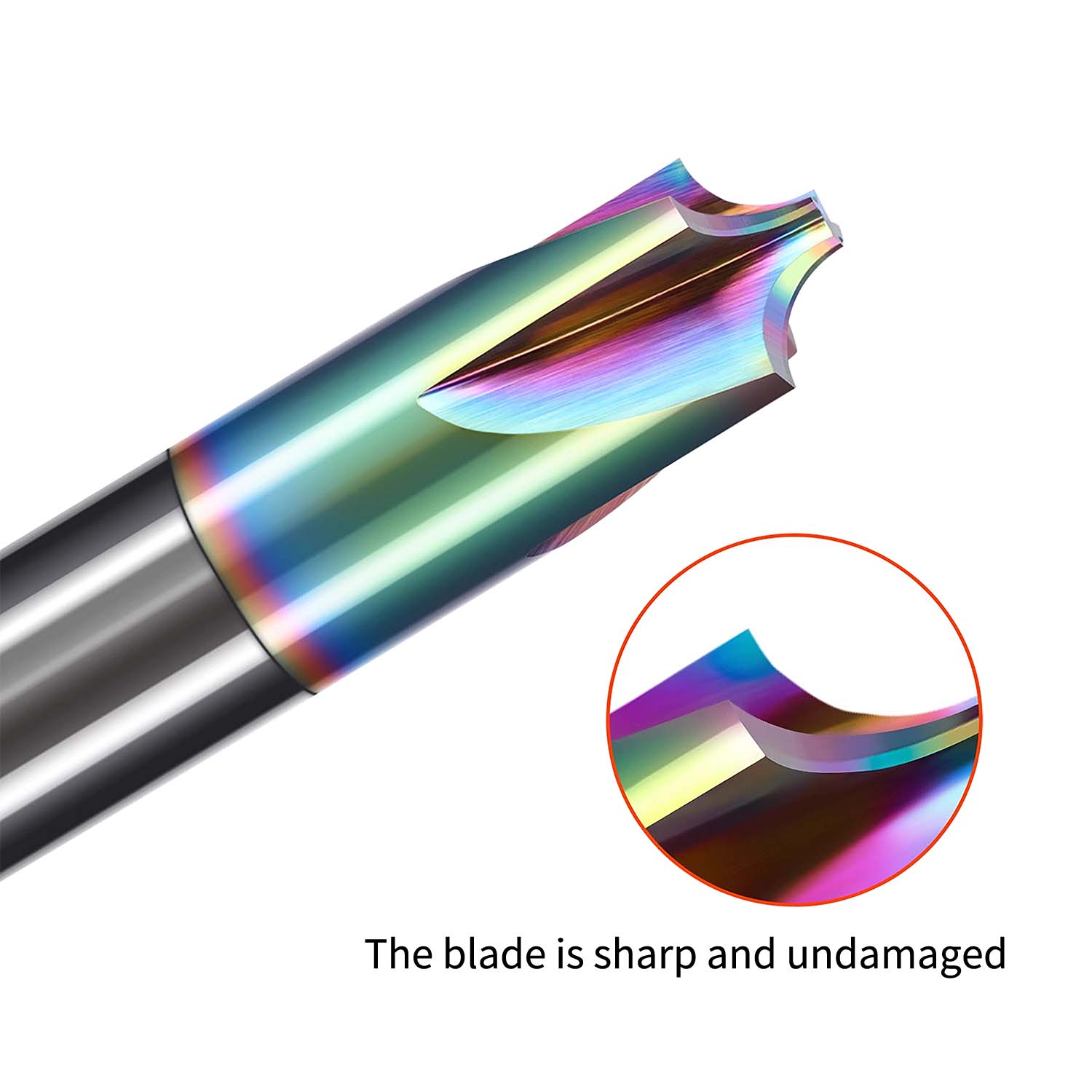

Innovative edge treatment technology: Through precise blunting (rounding) processing, microscopic defects resulting from edge grinding are completely eliminated, creating a smooth and uniform cutting edge. This not only significantly reduces the risk of chipping but also evenly distributes cutting stress, fundamentally enhancing the reliability and durability of the tool.

2. Extremely high processing accuracy and excellent surface quality

Precision manufacturing guarantee: The cutting tools undergo high-precision grinding, with strict control of tolerances, ensuring consistent and precise internal R-angles. This enables reliable repeat accuracy in mass production and meets the requirements for precision part processing.

Optimized geometric design: The unique four-edge design and customized helical angle ensure the smoothness and low vibration during the processing, directly achieving the effects of "excellent surface finish of the workpiece" and "integral molding without burrs", and reducing the subsequent machining processes.

Sharp cutting edge and stable cutting: The sharp cutting edge, combined with the enhanced edge treatment, enables clean and efficient cutting while effectively preventing the formation of burrs, ensuring the clear outline and precise dimensions of the processed workpiece.

3. Excellent processing efficiency and stability

For high-speed machining (HSM) optimization: Advanced tool geometries are specifically designed for efficient milling strategies, allowing for higher spindle speeds and feed rates, thereby achieving high processing efficiency.

Outstanding chip removal and anti-sticking blade performance: The optimized chip retention groove design provides a larger chip retention space, combined with precise helical angles, achieving smooth and efficient chip removal and the "non-sticking blade" effect. This avoids blade overheating, wear, or accidental damage caused by chip blockage, ensuring the stability and safety of long-term continuous processing.

4. Widespread applicability and reliability

Widely applicable: Particularly suitable for semi-finishing and finishing of internal rounded corners (transition arcs) in molds, stamping dies, automotive parts, and general engineering components with high requirements.

Strong adaptability to working conditions: The robust design makes it less prone to fracture. The strong coating combined with the base material can handle various challenges, including difficult-to-machine materials. It can maintain stable performance even under harsh processing conditions, making it an ideal tool for enhancing production reliability.

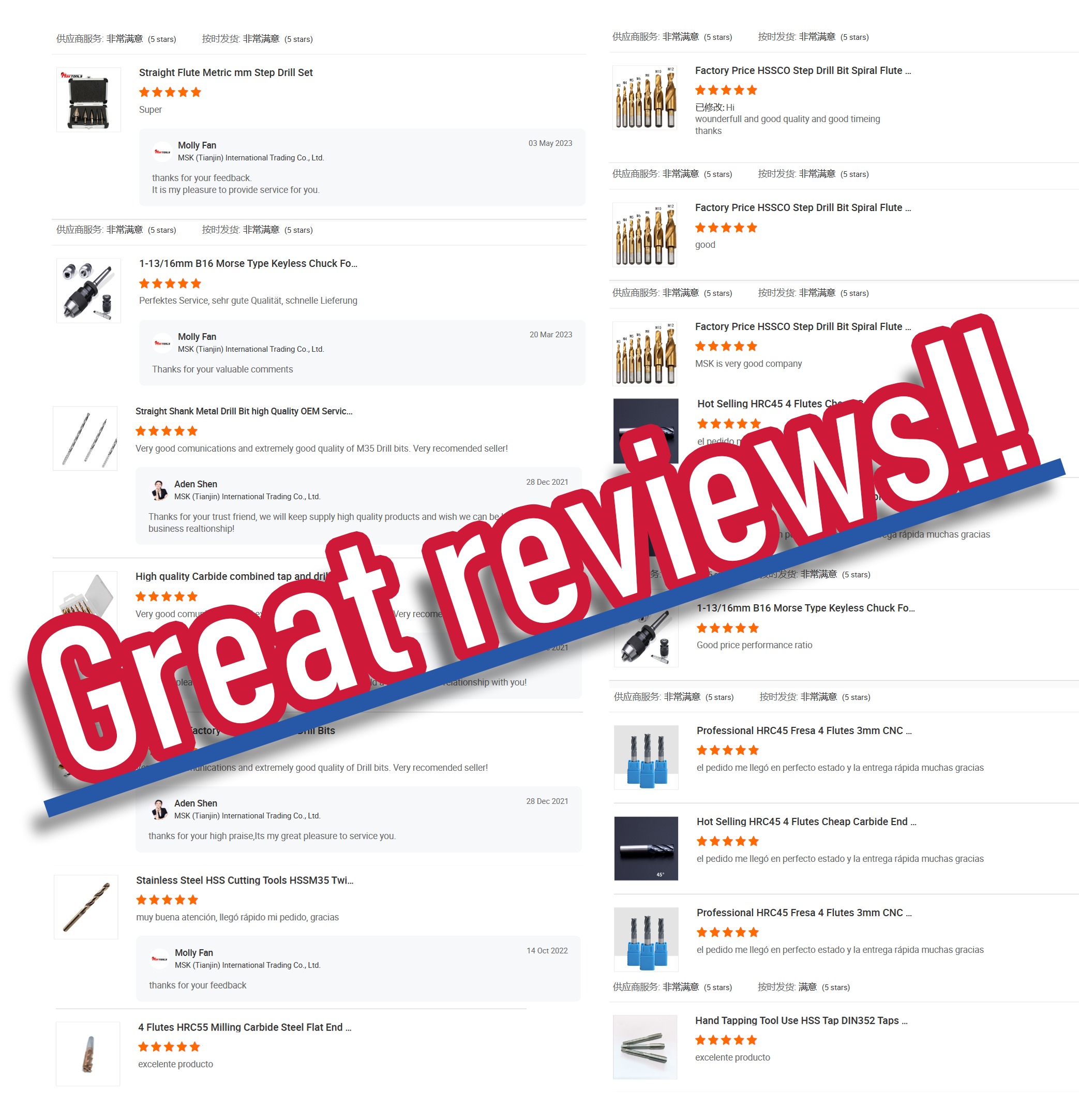

Why Choose Us

Factory Profile

FAQS

Q1.What are the main technical highlights of this high-performance internal R-profile milling cutter?

A:This tool integrates three core technologies: 1) Ultra-fine grain hard alloy substrate and advanced AlTiN/DLC coating, providing ultimate hardness, heat resistance and wear resistance; 2) Optimized four-edge design and helical angle, achieving low vibration, low cutting force and excellent chip removal; 3) Full-edge precision grinding and passivation treatment, ensuring consistent R-profile accuracy, smooth and uniform cutting edges, effectively reducing edge breakage and burrs, and optimized for high-speed machining (HSM) strategies.

Q2. How do the "one-piece molding" and "precise grinding" of the cutting tools affect the processing results?

A:The "one-piece molding" process ensures the overall strength and rigidity of the tool structure, reducing vibrations at their source. The "precise grinding" ensures that the internal R-angle size, edge shape and contour accuracy of each tool are strictly controlled within extremely small tolerances. This means that in batch processing, you can achieve extremely high repeatability accuracy and consistency, achieving stable one-piece molding effect and smooth surface quality without burrs.

Q3. How should the AlTiN coating and the DLC coating be selected? And for what scenarios are they respectively applicable?

A:AlTiN coating: It possesses extremely high hardness and outstanding high-temperature stability. It performs exceptionally well under high-speed and high-temperature cutting conditions, and is particularly suitable for processing materials such as steel, cast iron, stainless steel, and high-temperature alloys. It is an extremely versatile choice.

DLC coating (Diamond-like Carbon coating): The surface friction coefficient is extremely low, and it has extremely strong wear resistance and anti-adhesion properties. It is particularly suitable for processing有色金属 (such as aluminum alloys), graphite, composite materials and viscous materials, effectively preventing chip formation and achieving excellent surface finish. You can choose it based on the characteristics of the material to be processed.

Q4. How is the "efficient chip removal" and "low cutting force" design of the tool achieved?

A:This is attributed to our fluid dynamics-optimized groove shape and the specific helical angle design. This combination can:

Expand the chip retention space to facilitate the curling and expulsion of the chips.

Guide the chips to smoothly exit the processing area, avoiding entanglement and secondary cutting.

Reduce the friction between the cutting tool and the workpiece as well as the chips, thereby significantly reducing the cutting force and cutting heat. Ultimately, achieve a smoother cutting process, higher processing efficiency, and protect the cutting tool and the machine tool spindle.

Q5. In which industries and applications is this tool most advantageous to be used?

A:This tool is an ideal choice for fields such as mold manufacturing (e.g. cavities, electrodes), automotive components (e.g. engine parts, chassis parts), and general mechanical engineering parts. It is particularly suitable for situations that require high-precision inner corners, transition surfaces, semi-finishing and finishing of cavities. The design goal is to ensure excellent surface quality and dimensional accuracy while maximizing processing efficiency and tool life.