Milling Cutter Bar – High Precision Industrial Metal Cutting Tools

Milling Cutter Bar This high-strength square shoulder Milling Cutter Bar features a double-sided contact interface and a 42CrMo cutter body, ensuring outstanding stability and low vibration. Its precise design achieves micron-level runout, and combined with internal cooling, significantly enhances processing accuracy and tool life. The product is compatible with standard blades and is suitable for multi-functional requirements ranging from rough machining to semi-finishing.

Important Attributes

Product Features

1.Strive for excellence and quality assurance

Focusing on the cutting tool industry, choose us for more professionalism

2.The rapid cutting and chip removal are smooth

It is suitable for groove cutting processing, slope processing and corner cleaning processing

3.42crmo Material Is Highly Hard And Shock-Resistant

High-quality materials ensure the rigidity of the product, and the heat treatment process enhances the hardness and shock resistance of the knife body

4.The blade fits tightly without chipping

High precision, the screw position fastening design ensures that the blade groove closely adheres to the blade without chipping, with strong rigidity and better processing effect

5.Effective clearance to prevent friction

During processing, the milling cutter shank and the workpiece are effectively avoided to prevent friction on the workpiece during processing, and the clearance provides a larger chip space during processing

6.Quenching and hardening make milling easy

It features quenching hardening, excellent shock resistance, reduced blade wear, durability, stable performance, extended service life and improved processing efficiency

Advantages

1. Superior Rigidity, Vibration Resistance, and Stability

Double-sided Contact Positioning Interface: Utilizing an advanced end-face and conical surface dual-contact design, it achieves a large-area, tight fit with the machine tool spindle or extension rod, ensuring extremely high connection rigidity and torque transmission capability, effectively suppressing vibration and laying the foundation for heavy-duty cutting and high-speed machining.

Rugged Tool Holder Body: Manufactured from high-quality 42CrMo, precision-machined and heat-treated, it possesses excellent mechanical strength and wear resistance, ensuring dimensional stability over long-term use.

2. Precise Radial Positioning Accuracy

Precise manufacturing tolerances and interface design ensure extremely low radial runout after tool installation (typically down to the μm level). This is crucial for achieving excellent surface finish, ensuring workpiece dimensional accuracy, and extending tool life, especially suitable for high-precision contour machining and square shoulder milling.

3. Efficient Coolant Supply

Standard internal cooling channel design allows high-pressure coolant to be directly sprayed onto the cutting edge of the insert. This effectively reduces cutting temperature, facilitates timely chip removal, prevents built-up edge formation, and significantly improves performance and tool life in deep grooving, difficult-to-machine materials, or high-speed machining.

4. Wide Versatility and Flexibility

Insert Compatibility: Designed for mounting standard indexable square or rectangular inserts, supporting a wide selection of inserts from multiple brands and materials, such as coated carbide and cermet, to accommodate machining of various materials from steel and stainless steel to cast iron and aluminum alloys.

Multi-functional Applications: Primarily used for 90-degree square shoulder milling, capable of machining highly perpendicular sidewalls and bottom surfaces in a single pass. It is also widely used in face milling, step milling, slot milling, and contour milling, making it a powerful tool for efficient roughing and semi-finishing.

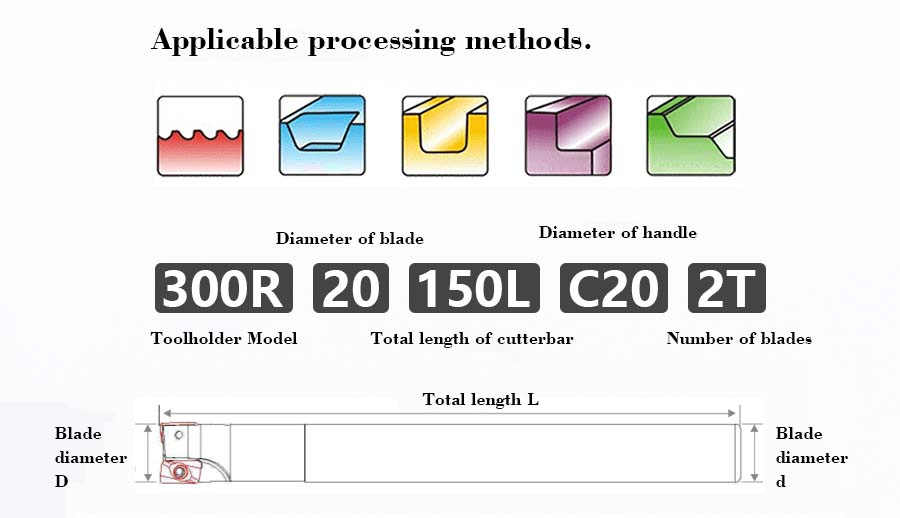

Multiple Specifications Available: Offers different diameters, lengths, and insert flutes (e.g., single-insert, double-insert types) to meet the power, machining space, and efficiency requirements of different machine tools.

Why Choose Us

Factory Profile

FAQS

1. Q: What makes your milling cutter bar exceptionally stable during heavy-duty cutting?

A: It features our patented double-sided contact interface (end-face + conical surface), which creates a large-area, tight fit with the machine spindle for maximum rigidity and vibration damping. Combined with a high-strength 42CrMo body, it ensures outstanding stability even under demanding loads.

2. Q: What level of machining precision can I expect with this tool?

A: The tool is engineered for high precision, with radial runout typically within micrometers (µm) after installation. This ensures excellent surface finish, tight dimensional accuracy, and extended tool life—especially in precision contouring and square shoulder milling.

3. Q: How does the internal coolant design improve performance?

A: The standard internal coolant channels deliver high-pressure coolant directly to the cutting edge. This effectively reduces heat, improves chip evacuation, prevents built-up edge, and enhances both tool life and performance in deep grooves, tough materials, and high-speed operations.

4. Q: Is this tool compatible with my existing inserts and materials?

A: Yes. It is designed to accept standard indexable square or rectangular inserts from leading brands, including coated carbide and cermet. This allows machining of a wide range of materials—from steel and stainless steel to cast iron and aluminum alloys.

5. Q: What applications and configurations are available?

A: Primarily used for 90° square shoulder milling, it is also highly effective in face, step, slot, and contour milling. Available in multiple diameters, lengths, and insert flute types (single or double), it can be configured to match your machine’s power, workspace, and efficiency needs for both roughing and semi-finishing.