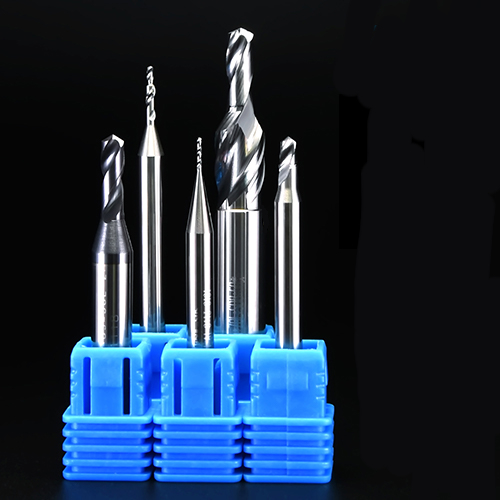

Saboda simintin carbide yana da ɗan tsada, yana da matukar muhimmanci a yi amfani da simintin carbide drills daidai don yin amfani da su mafi kyau don rage farashin sarrafawa.Daidaitaccen amfani da aikin carbide ya ƙunshi abubuwa masu zuwa:

micro rawar jiki

1. Zabi injin da ya dace

Carbide drillsza a iya amfani da shi a cikin kayan aikin injin CNC, cibiyoyin machining da sauran kayan aikin injin tare da babban iko da tsattsauran ra'ayi, kuma ya kamata a tabbatar da cewa tip runout TIR <0.02.Koyaya, saboda ƙarancin ƙarfi da ƙarancin ingantattun kayan aikin injin kamar su radial drills da injunan niƙa na duniya, yana da sauƙin haifar da rugujewar na'urorin carbide da wuri, wanda yakamata a guji shi gwargwadon iko.

2. Zabi hannun dama

Ana iya amfani da chucks na bazara, masu riƙe kayan aikin matsa lamba na gefe, masu riƙe kayan aikin na'ura mai aiki da ƙarfi, masu riƙe kayan aikin haɓakar thermal, da sauransu, amma saboda rashin isasshen ƙarfi na ƙwanƙwasa mai saurin canzawa, rawar rawar za ta zame kuma ta kasa, don haka yakamata ya kasance. kauce.

3. daidai sanyaya

(1) Sanyaya na waje ya kamata ya kula da haɗuwa da kwatancen sanyaya, samar da tsari na sama da ƙasa, kuma rage kusurwa tare da kayan aiki gwargwadon yiwuwa.

(2) Abun sanyaya na ciki yakamata ya kula da matsa lamba da kwarara, kuma yakamata ya hana yayyowar sanyaya daga tasirin sanyaya.

4. Daidaitaccen tsarin hakowa

(1) Lokacin da kusurwar karkata zuwa saman hakowa ya kasance> 8-10 °, ba a yarda ya yi rawar jiki ba.Lokacin <8-10 °, ya kamata a rage abincin zuwa 1 / 2-1 / 3 na al'ada;

(2) Lokacin da kusurwar kusurwar hakowa ta kasance> 5 °, abincin ya kamata a rage zuwa 1 / 2-1 / 3 na al'ada;

(3) Lokacin hako ramukan giciye (ramukan orthogonal ko ramukan da ba a iya gani ba), yakamata a rage abincin zuwa 1 / 2-1 / 3 na al'ada;

(4) An haramta sarewa guda 2 don reaming.

Lokacin aikawa: Mayu-16-2022