T Slot End Mill

The HRC55 four-edge T-slot milling cutter is made of high-quality integral hard alloy and TiSiN coating, featuring excellent wear resistance and high hardness. Its optimized four-edge design, combined with a large rake angle and large chip retention space, achieves low cutting heat, smooth chip removal, and stable cutting without sticking. The precise blunting treatment ensures a smooth and sturdy cutting edge, making it an ideal choice for efficient processing of various steel and aluminum alloy T-slot materials.

Important Attributes

| Product Name | HRC55 4-flute T-slot cutter | Brand | MSK |

| Coating | TiSiN coating | Number of flutes | 4 |

| Applicable materials | Ordinary steel, copper, alloy steel, carbon steel, tool steel, cast iron, etc | Applicable equipment | CNC machining centers, engraving machines, precision engraving machines, and other high-speed machines |

| Model NO. | MSKDT |

| Application | Stainless Steel/Alloy |

| Customized Support | OEM |

| Packing | Plastic Box |

| Place of Origin | China |

| Suitiable for | Metal |

| Precision | High Precision |

| Surface Finish | Tisin |

| Applicable Equipment | CNC Machining Centers, EngravingMachines |

| Transport Package | Plastic Box |

| Trademark | MSK |

| HS Code | 8207400000 |

| Flute Number | 4T |

| Product Name | China T-Slot End Mill Cutter |

| MOQ | 10PCS |

| Warranty | 3 Months |

| Keywords | T-Slot End Mill Cutting ToolFactories |

| HRC | 55 |

| Application Environment | Metal |

| Delivery Time | 7-15days |

| Shipment | DHL.TNT.UPS.FedEx. EMS.SfExpress |

| Specification | 4-12mm |

| Origin | Tianjin China |

| Production Capacity | 500 Per Week |

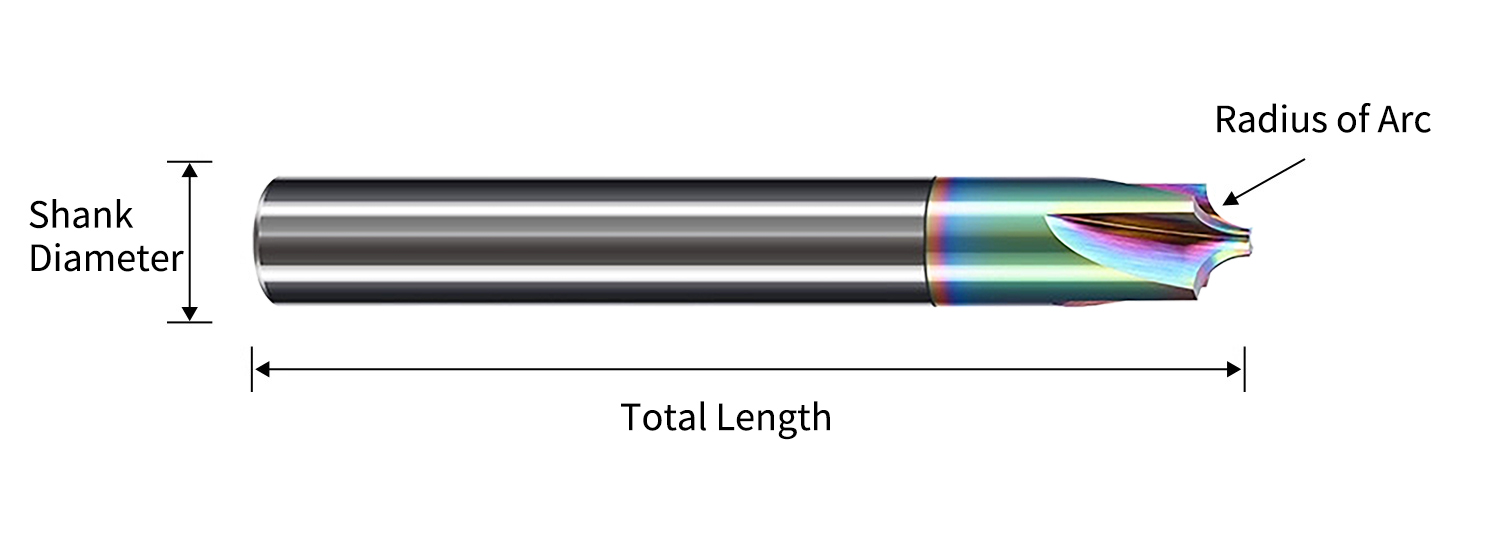

| Model | D | H | d | L | F |

| D4*1.0H*D4*50L*4F | 4 | 1 | 4 | 50 | 4 |

| D4*1.5H*D4*50L*4F | 4 | 1.5 | 4 | 50 | 4 |

| D4*2.0H*D4*50L*4F | 4 | 2 | 4 | 50 | 4 |

| D6*1.0H*D6*50L*4F | 6 | 1 | 6 | 50 | 4 |

| D6*1.5H*D6*50L*4F | 6 | 1.5 | 6 | 50 | 4 |

| D6*2.0H*D6*50L*4F | 6 | 2 | 6 | 50 | 4 |

| D6*2.5H*D6*50L*4F | 6 | 2.5 | 6 | 50 | 4 |

| D6*3.0H*D6*50L*4F | 6 | 3 | 6 | 50 | 4 |

| D8*1.0H*D8*60L*4F | 8 | 1 | 8 | 60 | 4 |

| D8*1.5H*D8*60L*4F | 8 | 1.5 | 8 | 60 | 4 |

| D8*2.0H*D8*60L*4F | 8 | 2 | 8 | 60 | 4 |

| D8*2.5H*D8*60L*4F | 8 | 2.5 | 8 | 60 | 4 |

| D8*3.0H*D8*60L*4F | 8 | 3 | 8 | 60 | 4 |

| D10*1.0H*D10*60L*4F | 10 | 1 | 10 | 60 | 4 |

| D10*1.5H*D10*60L*4F | 10 | 1.5 | 10 | 60 | 4 |

| D10*2.0H*D10*60L*4F | 10 | 2 | 10 | 60 | 4 |

| D10*2.5H*D10*60L*4F | 10 | 2.5 | 10 | 60 | 4 |

| D10*3.0H*D10*60L*4F | 10 | 3 | 10 | 60 | 4 |

| D12*1.0H*D12*60L*4F | 12 | 1 | 12 | 60 | 4 |

| D12*1.5H*D12*60L*4F | 12 | 1.5 | 12 | 60 | 4 |

| D12*2.0H*D12*60L*4F | 12 | 2 | 12 | 60 | 4 |

| D12*2.5H*D12*60L*4F | 12 | 2.5 | 12 | 60 | 4 |

| D12*3.0H*D12*60L*4F | 12 | 3 | 12 | 60 | 4 |

Product Features

GRC55 4-flute steel T-slot cutter

Sharp and wear-resistant

TiSiN Coating

Large core diameter design

Extra-large chip removal space

Advantages

1.Outstanding material performance

High hardness and toughness: Made with high-quality integral hard alloy (tungsten steel), the base material has a hardness reaching the HRC55 standard. This ensures extreme wear resistance while also offering excellent impact toughness, effectively preventing chipping and fracture.

Precision blunting treatment: All cutting edges are professionally blunted to eliminate microscopic defects, making the edge smooth and uniform. This can evenly distribute the cutting stress, significantly reduce the risk of initial edge breakage, and fundamentally enhance the stability and service life of the cutting tool.

2. Optimized geometric design

Efficient four-edge design: The four-edge structure not only ensures high cutting efficiency but also achieves the best rigidity balance and cutting stability.

Extra large chip storage space and sharp rake angle: The unique slot design provides an extremely large chip storage area, combined with the optimized rake angle design, can significantly reduce cutting heat and cutting force. This fundamentally solves the "sticking of the tool" problem when processing viscous materials (such as aluminum, mild steel), ensuring smooth chip discharge and protecting the tool and the surface of the workpiece.

High rigidity integral molding: The integrated design and robust blade structure of this product enhance the tool's resistance to deformation and vibration when processing deep grooves or performing side milling, making it less prone to breaking.

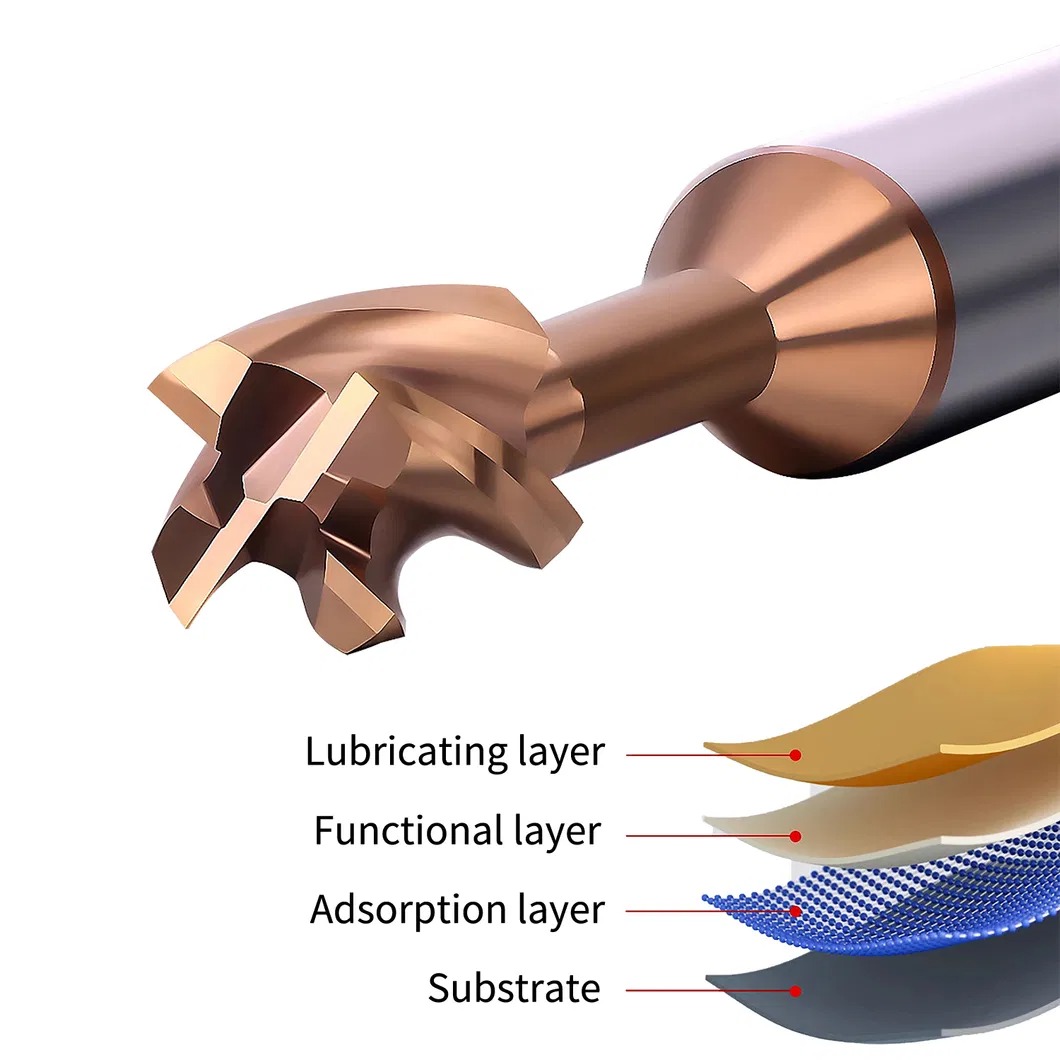

3. Advanced surface technology

High-performance TiSiN coating: Utilizing the upgraded TiSiN coating, it features extremely high hardness, excellent thermal stability, and low friction coefficient. It can provide continuous protection for the cutting edge during high-speed milling, significantly enhancing wear resistance, preventing the formation of thermal cracks and chip fragments, and is the key to achieving long-lasting sharpness and extended lifespan.

4. Widespread Application and Reliability

Powerful versatility: Optimized for T-slot processing, it can also handle various types of slot processing, side milling, and contour machining for materials such as steel, alloy steel, stainless steel, and aluminum alloy.

Precision manufacturing guarantee: Through a strict quality control system and precise manufacturing processes, we ensure the dimensional accuracy and performance consistency of each tool, providing reliable processing repeatability for mass production.

Professional customization support: As the original equipment manufacturer, we can offer OEM/ODM services. Based on your specific workpiece materials, machine conditions and processing requirements, we can provide optimized tooling solutions and technical support.

Why Choose Us

Factory Profile

FAQS

Q1.What are the core advantages of this HRC55 T-type slot milling cutter?

A:This product is specifically designed for high-hardness and high-efficiency machining. Its core advantage lies in its four-in-one high-performance combination:

Top-grade substrate: Utilizing high-quality integral hard alloy, the substrate hardness reaches HRC55, ensuring that the tool has excellent wear resistance from the inside out.

Optimized geometric design: Four-edge design combined with a large chip-removal groove and large rake angle fundamentally reduces cutting heat, enabling powerful cutting and smooth chip removal.

Advanced coating: Equipped with TiSiN upgraded coating, it significantly enhances the tool's high-temperature wear resistance and anti-chip-breaking ability.

Precise edge treatment: The ground cutting edge is treated with passivation, which is smooth and uniform, evenly dispersing stress and significantly improving the tool's stability and lifespan under heavy-load cutting.

Q2. What specific benefits do the "large rake angle design" and "extremely large chip evacuation space" bring in actual processing?

A:Large rake angle design: It significantly reduces cutting force and cutting heat, making the cutting process more smooth. This not only reduces the risk of workpiece deformation and material hardening during processing, but also fundamentally solves the problems of tool sticking and chip lumps caused by heat accumulation, especially suitable for processing stainless steel, aluminum alloys and other sticky materials.

Extremely large chip evacuation space: Ensures that long chips or sticky chips can be quickly and smoothly discharged outside the slot, effectively avoiding the risks of chip entanglement, tool rubbing, even chip breakage or tool breakage due to poor chip evacuation. The combination of the two achieves the processing effect of "sharp and wear-resistant without chip sticking, strong rigidity and not prone to breakage".

Q3. What is the special significance of the TiSiN coating for T-slot machining?

A:T-slot machining is a type of closed or semi-closed slot milling, where the side of the tool and the slot wall have severe friction, resulting in poor heat dissipation conditions. The requirements for the wear resistance, heat resistance and lubricity of the coating are extremely high. Our TiSiN coating has extremely high hardness and can form a stable oxide layer at high temperatures, providing long-lasting protection. It can effectively resist the side-edge wear caused by slot wall friction, prevent chipping of the cutting edge due to thermal shock during high-speed milling, ensure that the cutting edge remains sharp throughout the machining process, thereby achieving stable and smooth T-slots with high surface finish, and significantly extend the tool life.

Q4. Which materials and processing scenarios is this T-slot milling cutter mainly applicable to?

A:This tool is highly versatile in design and excels in processing steel (such as mold steel, structural steel), stainless steel, cast iron, and aluminum alloys. It has been specifically optimized for efficient and high-precision milling of standard or non-standard T-slots, keyways, stepped surfaces, and cavities on vertical or horizontal machining centers. It can provide stable and reliable performance for both single-piece production and batch processing.

Q5. As a professional manufacturer, what customization services and support can you offer?

A:We are a professional manufacturer of hard alloy cutting tools with a strict quality control system. Besides providing standard products, our strong R&D and production capabilities can offer you:

OEM/ODM services: Customized T-slot milling cutters with special dimensions, profiles, coatings or handle types according to your drawings or requirements.

Non-standard solutions: Provide professional technical support such as tool selection and parameter optimization for your specific workpiece materials, profiles or processing difficulties.

Global supply: Our products are sold worldwide and the quality has been verified by the market. We are committed to being your reliable long-term partner in the field of efficient cutting. Please feel free to contact us at any time for quotations and technical consultation.