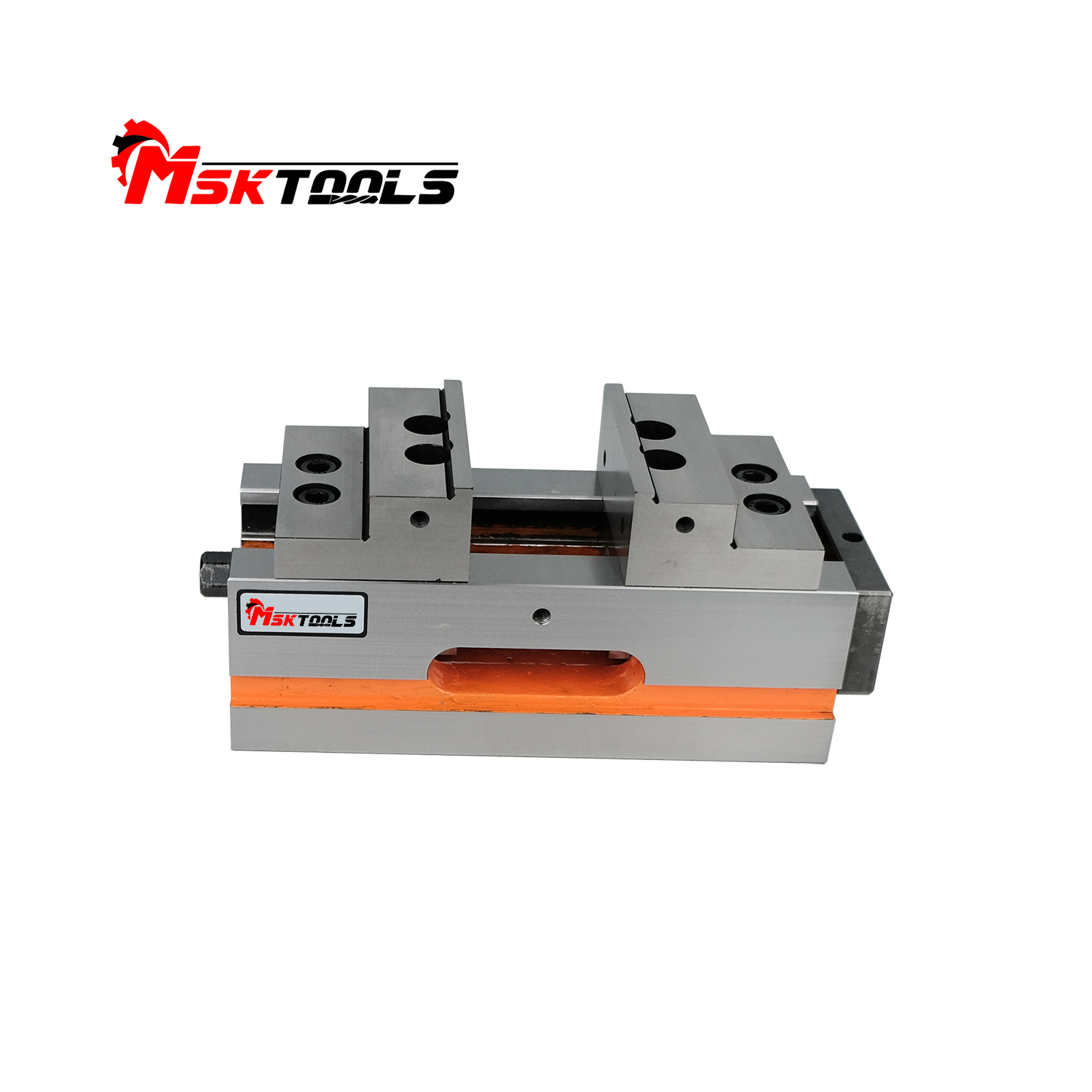

Self Centring Vise

This product is a high-precision automated pneumatic-hydraulic vise, designed specifically for precision machining on 4-axis, 5-axis, CNC indexing, and vertical/horizontal CNC milling machines. Its special structure effectively prevents workpiece lifting due to the downward pressure generated during clamping, ensuring excellent locking force and a center repeatability accuracy of ±0.01mm. The vise's side slides are hardened and heat-treated (HRC42° or higher), providing high wear resistance and tensile strength. The bidirectional jaw design allows for flexible reversal of orientation, perfectly adapting to various automated production needs from light machining to heavy cutting.

This product is specifically designed for multi-axis high-precision machining, perfectly suited for precision operations on 4-axis, 5-axis, CNC indexing tables, and vertical/horizontal CNC milling machines. Its vise center repeatability is consistently maintained at ±0.01mm, ensuring high consistency and reliability throughout the machining process.

The vise jaws are made entirely of steel and heat-treated to HRC42° or higher, ensuring excellent wear resistance and tensile strength. The unique bidirectional design allows the jaws to be switched for different clamping directions, offering flexibility and efficiency. The unique structure generates effective downward pressure during clamping, significantly preventing workpiece lift and providing excellent and stable locking force.

What customers say about us

FAQ

1. Which machine tools and equipment is this vise suitable for?

A: This product is designed for high-precision machining and is widely applicable to 4-axis and 5-axis machining centers, CNC indexing machines, and vertical or horizontal CNC milling machines. Its ingenious design is particularly suitable for complex cutting on 5-axis multi-axis machining centers, allowing it to be perfectly integrated into modern precision manufacturing production lines.

2. What is the repeatability of the vise? What is the significance of this for machining?

A: The center repeatability of this vise can be stably maintained within ±0.01mm. This extremely high precision means that in batch processing or complex processes requiring multiple clamping, the workpiece reference position remains consistent, fundamentally ensuring dimensional consistency and ultra-high precision, a key guarantee for precision machining.

3. What are the characteristics of the jaws? How is high versatility achieved?

A: The vise jaws are made entirely of steel and heat-treated to HRC42° or higher, possessing extremely high wear resistance and rigidity. Its bidirectional detachable design allows users to flexibly adjust or change the direction of the jaws according to the shape and requirements of the workpiece being clamped, significantly improving the flexibility and applicability of the clamping solution.

4. How does the product solve the common problem of workpieces floating during machining?

A: This vise, through a special structural design, actively generates a downward force when clamping the workpiece. This force effectively counteracts the upward tendency of the workpiece caused by cutting forces, excellently preventing workpiece floating and vibration, thus ensuring excellent locking force, making the machining process more stable and the surface quality higher.

5. How does the design of the slide rails ensure long-term accuracy and durability?

A: The sliding rails on both sides of the vise undergo hardening heat treatment (HRC42°). This treatment gives the slide rails extremely high hardness, wear resistance, and tensile strength. Even under long-term, high-frequency use, it can effectively resist wear and deformation, thus ensuring the vise's overall high precision and ultra-long service life.

This product is a high-performance automated vise designed specifically for modern precision manufacturing. It integrates a high-rigidity structure, precise clamping force control, and an intelligent automation interface, aiming to meet the stringent requirements from complex multi-axis machining to high-efficiency mass production.

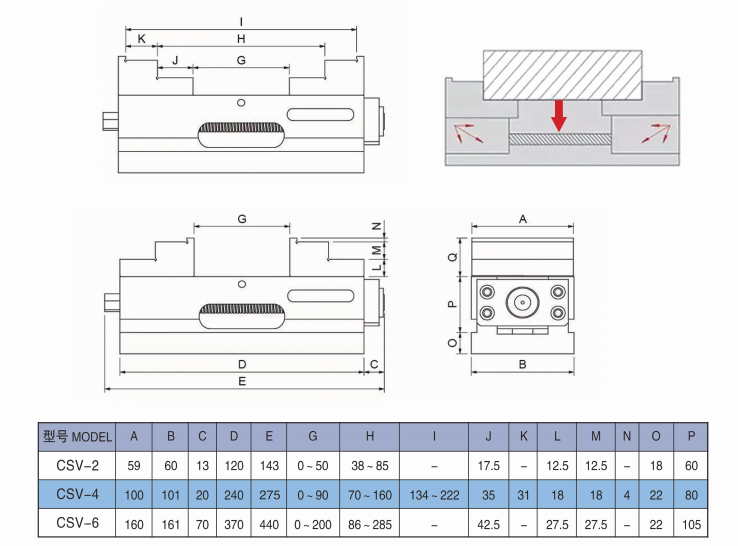

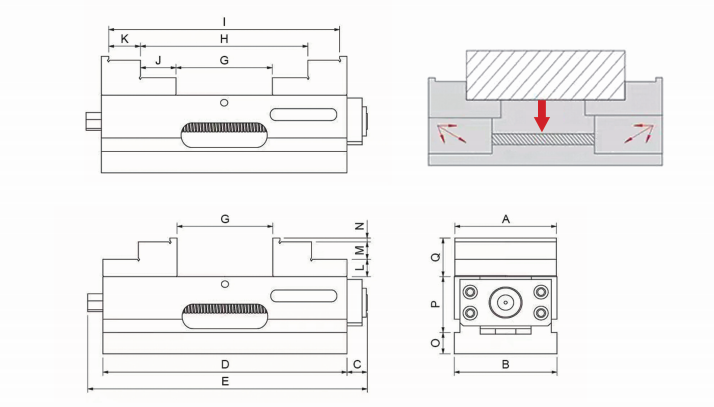

I. Design and Composition

High-Strength Body: The vise body is made of high-tensile-strength spheroidal graphitized cast iron (FCD600), ensuring a robust basic structure and strong resistance to deformation.

Precision Hardened Guide Rails: The slide rails on both sides of the vise are hardened and heat-treated to HRC42 or higher, achieving high wear resistance, high tensile strength, and long-term stable high precision.

Modular Jaws: The jaws feature a bidirectional design made entirely of steel. After heat treatment (HRC42° or higher), they can be disassembled and repositioned according to clamping needs, offering high flexibility.

Core Drive System: It incorporates a self-developed reciprocating pneumatic motor, which drives the hydraulic circuit through pneumatic pressure. Combining the advantages of rapid pneumatic response and stable hydraulic force transmission, it achieves efficient automated drive.

Floating Downward Pressure Mechanism: A specially designed internal floating downward pressure transmission mechanism generates additional downward pressure during clamping.

II. Core Functions

Superior Clamping Force and Stability:

The clamping force can be freely and precisely adjusted from 0 to 6000 kg via a pressure regulator, adapting to various machining conditions from light alloys to cast iron blanks.

Automatic Pressure Holding and Stabilization Function: Even with fluctuations in air source pressure, the set clamping force is maintained, ensuring machining safety.

Excellent Anti-Workpiece Floating Capability: The unique floating downward pressure mechanism generates a locking force, effectively preventing the workpiece from floating or tilting during machining, providing excellent locking force.

Extremely High Precision and Repeatability:

Center repeatability accuracy up to ±0.01 mm, providing a reliable reference for precision machining.

The bidirectional center repeatability structure ensures the accuracy of the machining position.

Highly Efficient Automated Operation:

Fast opening and closing speed, switching speed of only 1.5 seconds, and a clamping safety distance of 6 mm significantly improve non-machining time efficiency.

Offering multiple control interfaces, this product can directly interface with CNC system signals for fully automated clamping, or be operated manually via switches, electric valves, or machine tool controllers.

III. Application Areas

This product is designed for demanding precision machining scenarios, particularly suitable for:

Multi-axis and Composite Machining: Perfectly compatible with 4-axis and 5-axis machining centers and CNC indexing tables for continuous machining of complex contours.

Machining with High Rigidity Requirements: Suitable for vertical and horizontal CNC milling machines, handling heavy cutting conditions on materials such as cast iron.

Automated Production Lines: Easily integrated into dedicated automated or unmanned production systems via automatic clamping/unclamping function for continuous operation.

IV. Challenges and Solutions in Precision Machining

In high-speed, multi-axis precision machining, the rigidity, accuracy stability, and vibration resistance of the clamp are key challenges. Traditional clamps often face problems such as workpiece displacement, decreased accuracy due to vibration, and low efficiency of manual clamping.

This product directly addresses these challenges through the following design features:

High-rigidity material and hardening treatment: Resists deformation and wear caused by cutting forces, ensuring long-term accuracy.

Downforce anti-floating design: Fundamentally solves the workpiece floating problem, ensuring machining stability and surface quality.

High repeatability and rapid automation: Provides a consistent reference for precision multi-faceted machining, reduces auxiliary time, and improves overall equipment efficiency (OEE).

This high-precision automated vise is a powerful tool in the field of precision manufacturing. With its FCD600 high-strength cast iron body, HRC42 hardened guide rails, adjustable clamping force of 0-6000kg, ±0.01mm repeatability, and integrated automation interface, it successfully solves the core challenges of workpiece fixation stability, accuracy maintenance, and production efficiency in precision machining. Whether used for five-axis complex surface machining or integrated into automated production lines, it provides a stable, reliable, and efficient clamping solution, making it a key piece of equipment for enhancing high-end manufacturing capabilities.