Spiral point taps are also known as tip taps and edge taps in the machining industry. The most significant structural feature of the screw-point tap is the inclined and positive-taper-shaped screw-point groove at the front end, which curls the cutting during cutting and discharges it to the front of the tap and the center of the screw hole.

Because of its special chip removal method, the screw-point tap avoids the chip interference with the formed thread surface, so that the quality of the finished threaded hole is better than that of the ordinary straight groove;

Shallow groove structure ensures cooling and strengthens the torque resistance in tap processing, so that it can have a higher rotational speed and is suitable for processing deep through-hole threads;

Due to the chip removal method of the screw tip tap, it is recommended for vertical machining and through-hole threading;

Generally speaking, compared with spiral flute taps, the life of spiral point taps can be extended by at least 1 times.

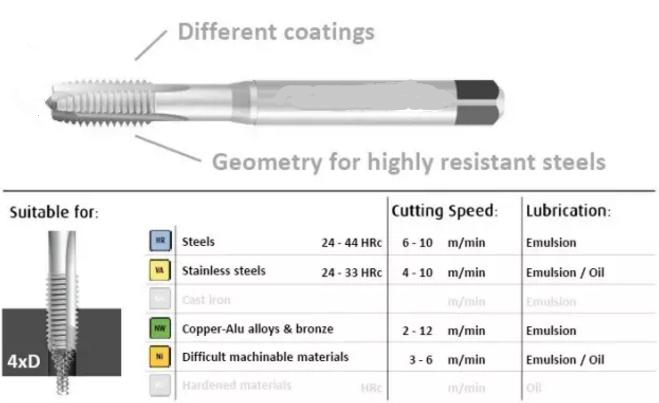

Machining hardness: ≤32HRC; Recommended speed: about 8~12m/min; Cooling medium: oil or ointment, emulsion cooling;

*The machining speed of the surface coated taps is correspondingly increased by 30%

Tap cutting parameters and groove shape After many cutting tests, we have set the parameters of the screw point tap for processing stainless steel, low, medium and high carbon steel, aluminum alloy, copper alloy, etc. The tap adopts a full grinding process, and the groove is processed at one time. Threads are processed on imported thread mills.

Post time: Jun-14-2022