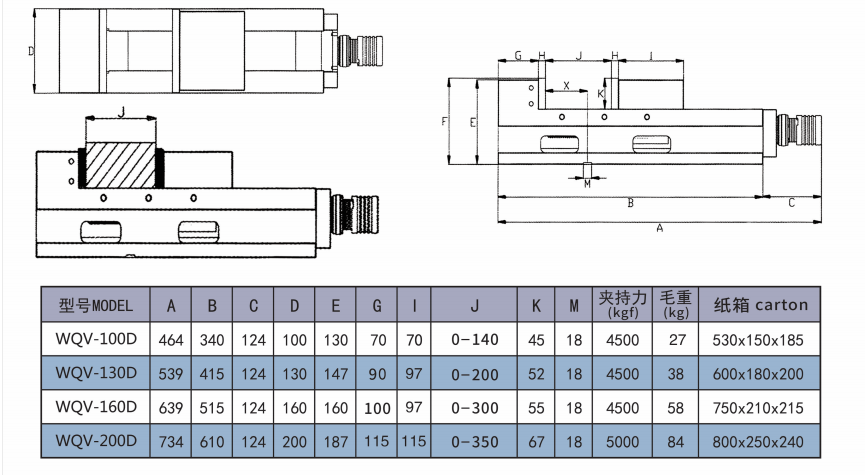

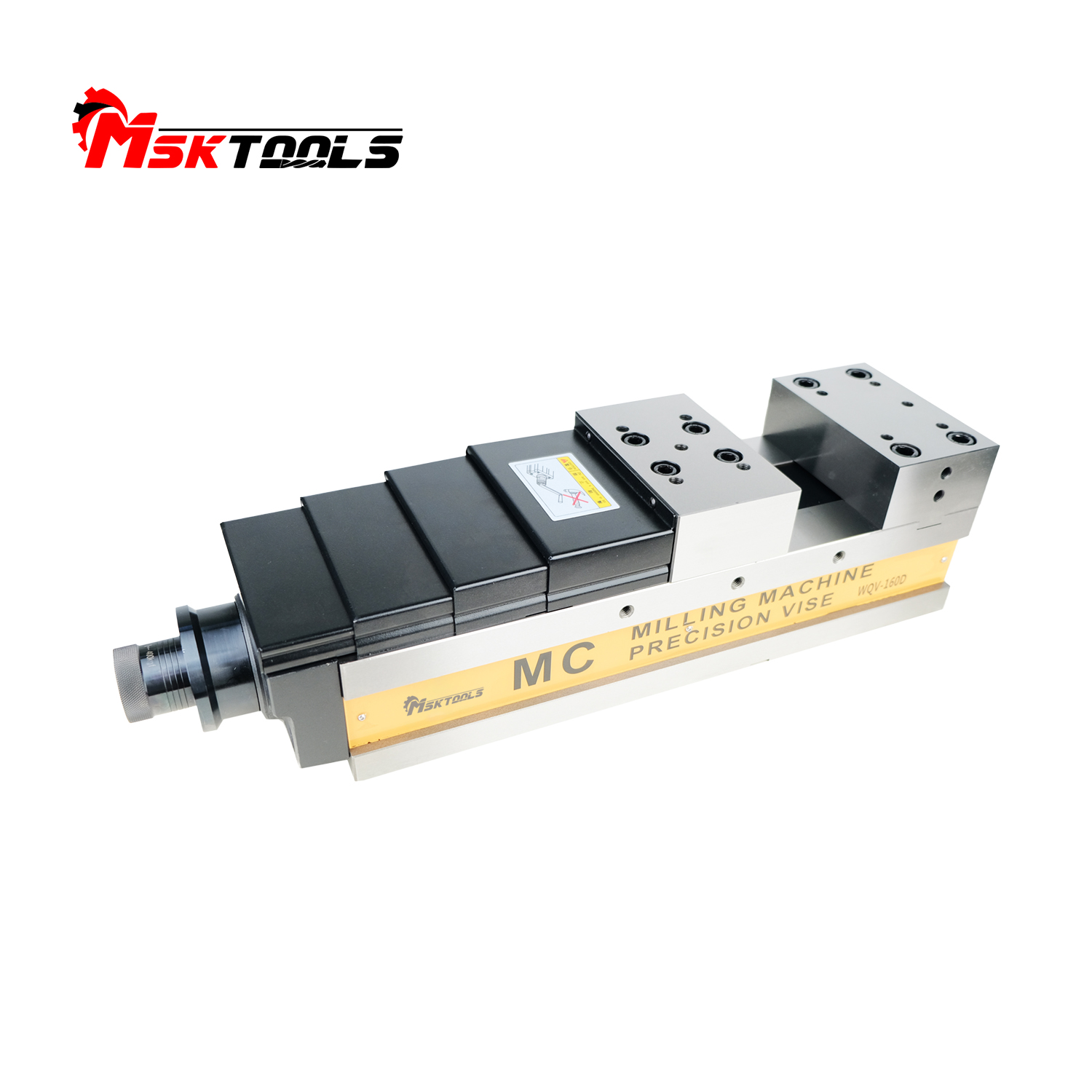

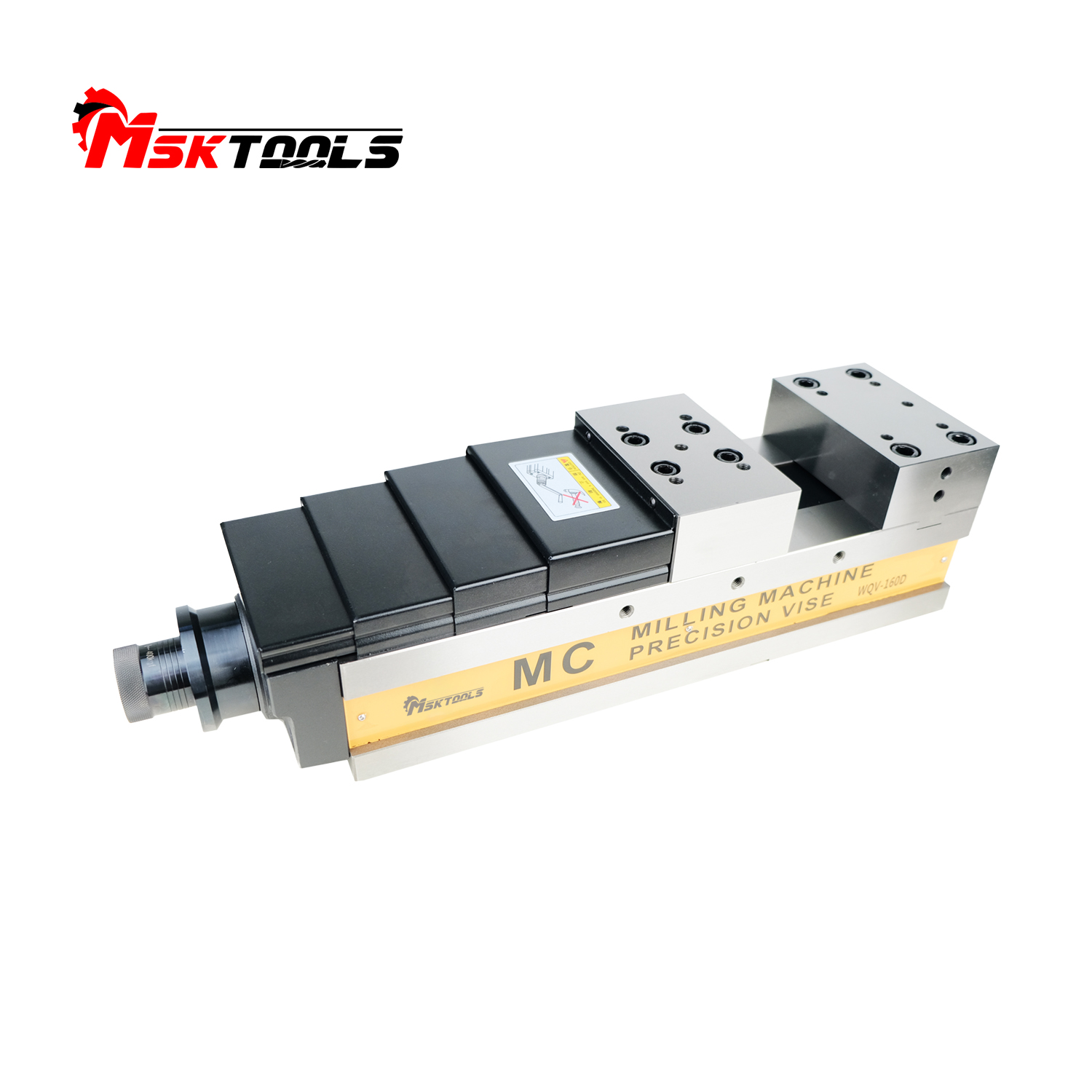

MC Precision Power Vise

The MC Precision Power Vise is made of FCD600 high-strength ductile iron in one piece, with key sliding components achieving a hardness of HRC42° or higher, providing excellent resistance to deformation and wear. Its patented hydraulic force-multiplying mechanism can quickly generate a powerful clamping force of up to 5000 kgf, and it is equipped with a special downward-pressing nut structure to effectively prevent workpiece floating and tilting during machining. The product is specifically designed for vertical/horizontal machining centers and FMS systems, suitable for various machining scenarios involving both light and heavy cutting.

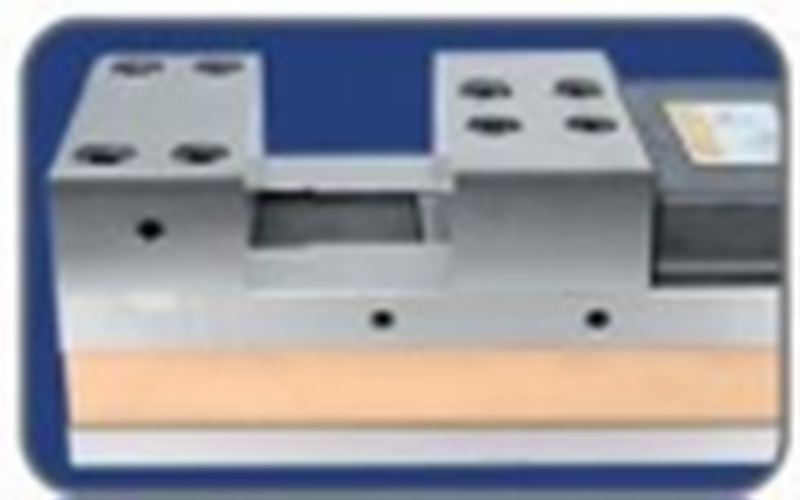

The internal floating downward pressure transmission can generate downward locking force and eliminate it Tiger mouth board floating and working tilt

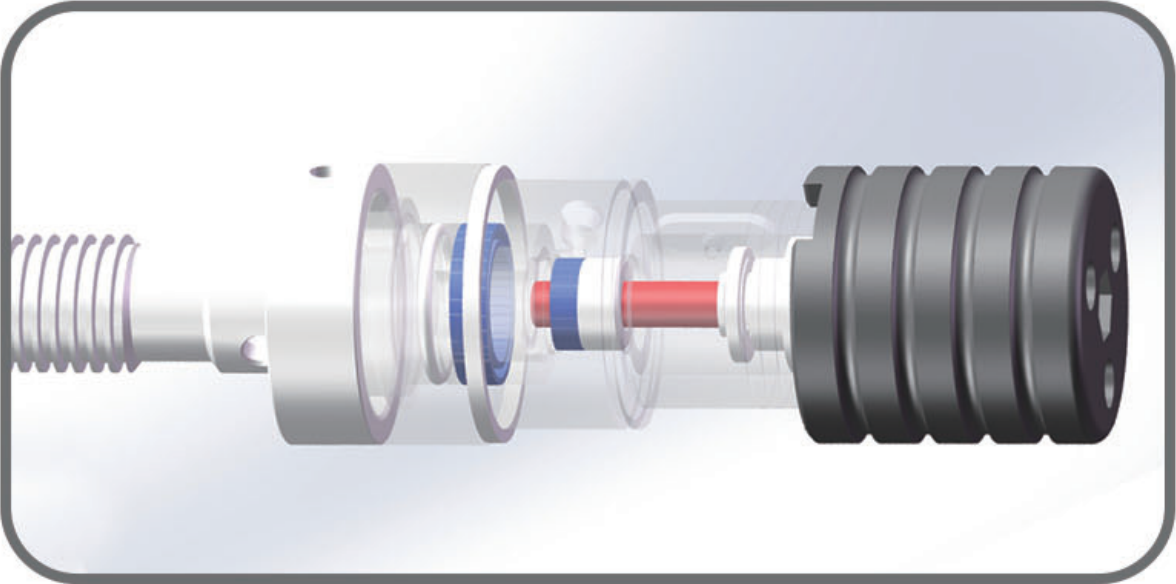

With its unique hydraulic sealing structure, you can achieve safe and pressure-free operation.

Replaceable step clamp clamping workpiece

The MC precision hydraulic vise is designed for vertical and horizontal machining operations and FMS systems. Its innovative hydraulic force-multiplying mechanism provides a powerful clamping force of up to 5000 kgf, ensuring stability under heavy cutting conditions. The vise is precision-cast from FCD600 high-strength ductile iron, with the slide rails and key components heat-treated to a hardness of HRC42° or higher, offering both high resistance to deformation and durable wear resistance.

The built-in downward-pressurizing nut structure generates a downward force simultaneously during tightening, effectively eliminating jaw lift and workpiece tilting issues. The modular jaw plate design allows for quick replacement according to machining needs, and the patented hydraulic system enables safe, pressure-free operation, making it an ideal fixture solution for improving the efficiency and accuracy of CNC machining centers.

What customers say about us

FAQ

1. Q: What machining scenarios is this hydraulic vise suitable for?

A: It is designed for high-load, high-precision machining needs, especially suitable for heavy cutting in vertical or horizontal integrated machining centers and flexible manufacturing systems (FMS). Its precise design also makes it perfectly capable of handling light cutting tasks.

2. Q: What is the core clamping force of the product? How is stable clamping prevented from loosening?

A: This product uses a patented hydraulic force-multiplying design, capable of generating a powerful clamping force of up to 5000 kgf. Simultaneously, its special built-in downward-pressing nut structure generates a downward locking force during horizontal clamping, fundamentally eliminating the risk of jaw plate floating and workpiece tilting, ensuring machining stability.

3. Q: What are the advantages of the product in terms of durability and precision retention?

A: There are three main advantages:

High-strength body: Made of FCD600 high tensile strength ductile iron in one piece, it is sturdy and not easily deformed.

Full Hardening Treatment: Key components such as the sliding surface of the vise body, the fixing block, and the slider undergo heat treatment, achieving a hardness of HRC42° or higher, ensuring long-term wear resistance and high precision retention.

Reliable Sealing: A unique hydraulic sealing structure ensures system safety and pressure resistance, guaranteeing long-term reliability.

4. Q: Can it clamp workpieces of different sizes and shapes? How flexible is it?

A: Yes, it is highly flexible. In addition to the standard flat jaws, the product also supports interchangeable stepped jaws to adapt to more diverse workpiece clamping needs. This modular design provides users with flexible processing solutions.

5. Q: What is the main difference between this vise and ordinary mechanical vises?

A: The main difference lies in the power source and performance:

Power and Efficiency: Utilizing a precision hydraulic system, operation is more effortless, quickly providing constant and powerful clamping force, far exceeding manual mechanical locking methods.

Function and Safety: Equipped with automatic pressure reduction and anti-floating function and pressure relief sealing design, it provides higher machining stability and operational safety under demanding working conditions such as heavy cutting, which is difficult to achieve with ordinary mechanical vises.

The MC Precision Hydraulic Vise is an industrial-grade clamping tool designed for modern high-load machining environments. It integrates a precision hydraulic force-multiplying mechanism with a high-rigidity structure, providing clamping forces up to 5000 kgf. It perfectly adapts to the heavy-cutting demands of vertical/horizontal machining centers and FMS flexible manufacturing systems, while also meeting the precision requirements of light-cutting operations. Design and Composition:

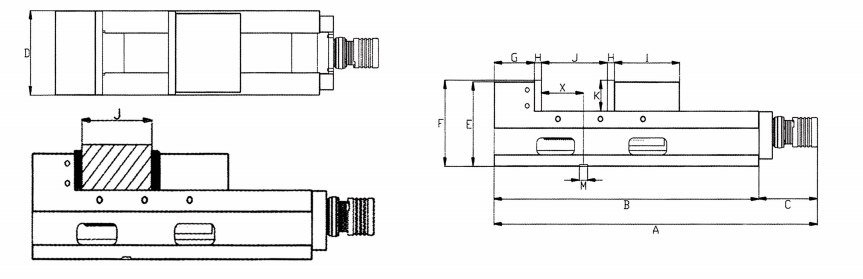

Main Structure: Constructed from a single piece of FCD600 high-strength ductile iron, with a tensile strength of 60 kg/mm² (80,000 psi), ensuring overall rigidity.

Key Components:

Hardened Guide Rails: The sliding surfaces of the body are precision ground and heat-treated to a hardness ≥ HRC42, ensuring long-term wear resistance and precision maintenance.

Modular Jaws: The fixing and sliding blocks are made of heat-treated steel (HRC42° or higher), supporting quick replacement of different stepped jaw plates to accommodate diverse workpieces.

Core Mechanism: An integrated floating downward pressure transmission mechanism and a unique hydraulic sealing structure form a highly efficient and safe power and locking system.

Core Functions

Powerful and Precise Clamping Force: Patented hydraulic design enables rapid pressurization, delivering a stable clamping force of up to 5000 kgf.

Active Anti-Floating and Anti-Tilting: A special downward-pressurizing nut structure generates a downward locking force simultaneously during tightening, effectively eliminating jaw floating and workpiece tilting.

Safety and Reliability: A unique hydraulic sealing structure ensures the system remains safe and pressure-free during long-term use, guaranteeing reliable operation.

High Adaptability and Flexibility: The replaceable stepped jaw design allows a vise to quickly adapt to workpieces of various shapes and sizes.

Application Scenarios

Main Equipment: Various CNC vertical/horizontal machining centers, FMS flexible manufacturing systems.

Machining Types: Particularly suitable for heavy-duty machining of steel and cast iron parts requiring heavy cutting, and also suitable for light cutting requiring high precision.

Production Modes: Applicable to various production modes from mass production to flexible manufacturing.

Value in Precision Machining

This product, through its extremely high structural rigidity and active downward locking function, provides crucial stability for heavy cutting, significantly suppressing vibration and improving surface finish and tool life. Simultaneously, its precision manufacturing and wear-resistant design ensure dimensional accuracy and repeatability over long-term use, making it a solution that balances both force and precision.

Challenges and Considerations

System Integration: Requires a stable hydraulic power source and places certain demands on workshop auxiliary facilities.

Initial Investment: As a high-end precision hydraulic clamp, its initial cost is higher than that of a mechanical vise.

Maintenance Knowledge: Requires operators and maintenance personnel to possess basic knowledge of hydraulic systems for daily inspection and maintenance.

The MC Precision Hydraulic Vise represents the development direction of modern, efficient, heavy-duty precision machining clamps. It perfectly integrates the extreme rigidity provided by the FCD600, the enormous and stable clamping force generated by patented hydraulic technology, and the unique downward anti-floating design. This product is not only a powerful tool for meeting heavy cutting challenges, but its precision and flexible design also make it a strategic equipment choice for improving overall machining efficiency and achieving complex process requirements.