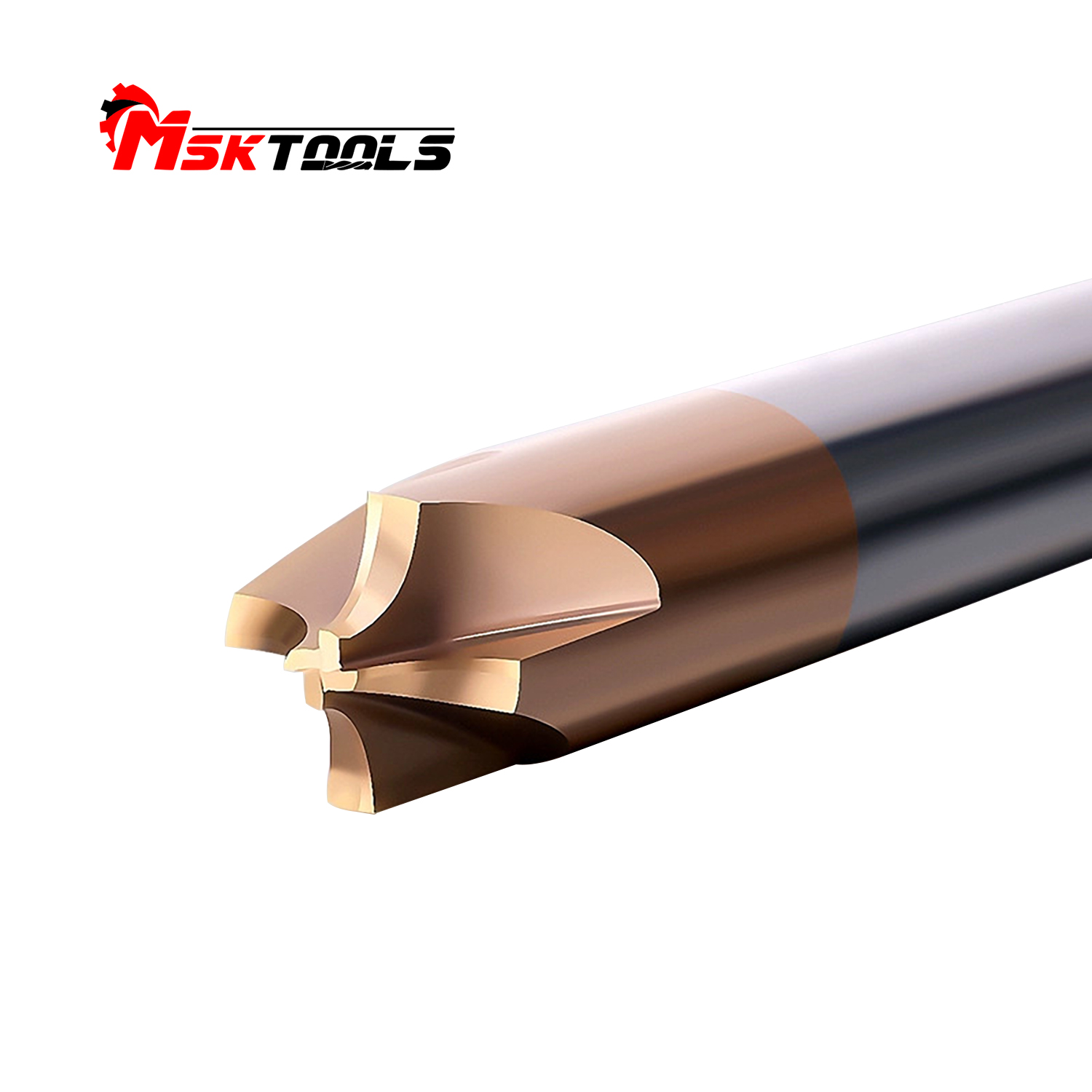

Inner R Angle End Milling Cutter

The hard alloy internal R arc cutter is equipped with a high-end tungsten steel substrate and TiSiN coating. Its four-edge design combined with precise internal R geometry ensures excellent processing stability and outstanding surface finish. The ground cutting edge, after passivation treatment, effectively enhances wear resistance and anti-breakage performance, enabling efficient chip removal and long-lasting sharpness. Specifically designed for semi-finishing and finishing of molds, aerospace and automotive parts, it offers longer tool life and reliable processing performance.

Important Attributes

| Product Name | Internal R-milling cutter | Brand | MSK |

| Item Number | MSKDT-130 | Coating | TiSiN coating |

| Applicable Machine Tool | Milling Machine | Machining range | 55°-58° |

| Applicable Materials | Alloy steel, tool steel, carbon steel, stainless steel, cast iron, ordinary steel parts, etc. |

Applicable Equipment | CNC machining centers, engraving machines, precision engraving machines, and other high-speed machines. |

| Model NO. | MSKDT-130 |

| Application | Stainless Steel/Alloy |

| Customized Support | OEM |

| Packing | Plastic Box |

| Place of Origin | China |

| Suitiable for | Metal |

| Precision | High Precision |

| Surface Finish | Tisin |

| Applicable Equipment | CNC Machining Centers, Engraving Machines |

| Transport Package | Plastic Box |

| Trademark | MSK |

| HS Code | 8207400000 |

| Flute Number | 4T |

| Product Name | Inner R Angle End Milling Cutter |

| MOQ | 10PCS |

| Warranty | 3 Months |

| Keywords | CNC Corner Radius Milling Cutter |

| HRC | 55 |

| Application Environment | Metal |

| Delivery Time | 7-15days |

| Shipment | DHL.TNT.UPS.FedEx. EMS.Sf Express |

| Specification | 4-20mm |

| Origin | Tianjin China |

| Production Capacity | 500 Per Week |

| Flute Diameter | Angle | Total Length | Flutes |

| D4 | R0.2 | 50L | 4T |

| D4 | R0.3 | 50L | 4T |

| D4 | R0.4 | 50L | 4T |

| D4 | R0.5 | 50L | 4T |

| D4 | R0.75 | 50L | 4T |

| D4 | R1.5 | 50L | 4T |

| D6 | R1.5 | 50L | 4T |

| D6 | R2 | 50L | 4T |

| D6 | R2.5 | 50L | 4T |

| D8 | R3 | 60L | 4T |

| D8 | R3.5 | 60L | 4T |

| D10 | R4 | 60L | 4T |

| D12 | R5 | 60L | 4T |

| D14 | R6 | 60L | 4T |

| D16 | R7 | 75L | 4T |

| D20 | R8 | 100L | 4T |

Product Features

TiSiN Coating

Upgraded coating for enhanced wear resistance, preventing chipping during rapid milling, ensuring a sharp cutting edge, and providing durabil

New cutting edge, blunted treatment

Increases the knife's corrosion resistance and wear resistance, making it sharp and durable with a burr-free edge, extending its service life.

Highly efficient chip removal, non-stick cutting

Larger chip capacity, powerful cutting, smooth chip removal, robust design that is less prone to breakage

Passivation treatment

Effectively solves microscopic defects on the cutting edge after tool sharpening, resulting in a smooth and even cutting edge that distributes stress evenly during machining. It reduces the risk of chipping and increases tool life.

Advantages

I.Outstanding wear resistance and service life

High-grade tungsten carbide substrate: Utilizing high-quality tungsten carbide material, it possesses excellent high hardness and resistance to deformation.

TiSiN composite coating: This upgraded coating technology significantly enhances wear resistance, effectively prevents blade chipping during rapid milling, maintains sharp edges, and greatly extends the lifespan of the cutting tool.

II. Precise processing quality and stability

4-blade design & precise internal R geometry: Optimizes the structure of the tool body to ensure high rigidity, low vibration, and achieve excellent processing stability and surface finish.

Passivation treatment process: Eliminate microscopic defects at the cutting edge, making the cutting edge smooth and uniform, with more reasonable stress distribution, reducing the risk of chipping, and improving processing consistency.

III. Efficient Cutting and Chip Removal Performance

Strengthened Cutting Edge Design: The sharpened cutting edge, after being treated with blunting, combines sharpness with strength, effectively preventing the generation of burrs and achieving clean processing.

Large chip-breaking groove design: The chips are discharged smoothly, the cutting force is evenly distributed, and chip adhesion is avoided. It is suitable for high-speed continuous processing.

IV. Widespread Applicability and Reliability

Suitable for semi-finishing and finishing processes in industries such as mold manufacturing, aerospace, and automotive components.

It can maintain its performance under high-temperature and high-load conditions, reduce the frequency of tool changes, and improve production efficiency and processing economy.

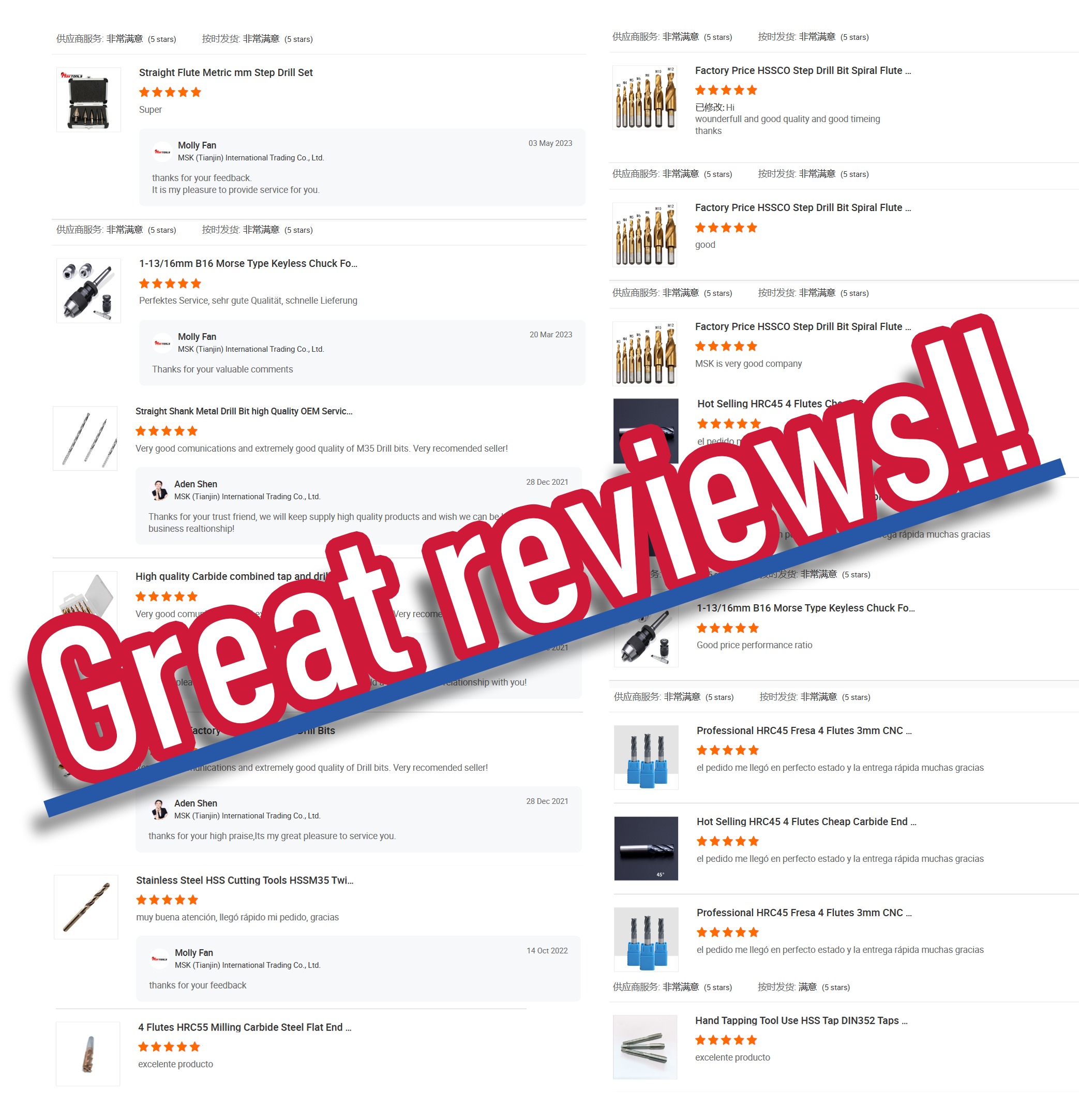

Why Choose Us

Factory Profile

FAQS

1.What are the advantages of this tool's TiSiN coating compared to traditional coatings?

Our TiSiN coating is an upgraded high-performance coating. It provides extremely high surface hardness while maintaining excellent heat resistance and chemical stability. This combination significantly enhances wear resistance, effectively prevents blade chipping during high-speed milling, ensures a consistently sharp cutting edge, and thus greatly extends the tool's lifespan, especially when processing difficult-to-machine materials.

2. What is "cutting edge hardening treatment"? What benefits does it bring to actual processing?

Hardening treatment is achieved through precise processes to eliminate microscopic defects (such as burrs and micro notches) that are invisible to the naked eye on the cutting edge after grinding. The treated cutting edge is smooth and uniform, and can evenly distribute cutting force and thermal stress during processing. This directly leads to three major benefits: reducing the risk of edge breakage, suppressing the generation of processing burrs, and significantly improving the stability and durability of the cutting tool.

3. How is the feature of "efficient chip removal and non-stick blade" of the tool achieved?

This is due to our carefully designed four-edge structure and precise internal R-shaped groove pattern. This design provides a larger chip storage space and a smoother chip removal path, ensuring that the chips can be discharged quickly and smoothly, avoiding the problems of chip entanglement or blockage that could cause stickiness or jamming of the blade. This guarantees the continuity of the machining process, improves the surface quality, and reduces the damage to the blade caused by poor chip removal.

4. For which processing scenarios and materials is this internal R-angle milling cutter mainly applicable?

Our internal R-angle milling cutter is a high-precision tool specifically designed for semi-finishing and finishing processes. It is particularly suitable for scenarios where surface smoothness and shape accuracy are highly demanded, and is widely used in industries such as mold cavities, aerospace structural components, and automotive parts. When processing various alloy steels, mold steels, stainless steels, and certain high-temperature alloys, it can demonstrate excellent stability and durability.

5. As a professional manufacturer, what are the distinctive features of your hard alloy matrix?

We use our independently developed high-quality tungsten-cobalt type hard alloy matrix. This matrix achieves the best balance between high hardness and high toughness, providing a solid foundation for the coating. Combined with the advanced TiSiN coating, the entire tool possesses excellent resistance to plastic deformation and wear resistance, and can maintain long-term dimensional stability and cutting performance even under high-speed and high-load processing conditions.