hrc60 Carbide 4 Flutes Standard Length End Mills

Product Introduction

Product specification

| Blade diameter | Blade length | Shank diameter | Total length |

| 3 | 8 | 3 | 50 |

| 3 | 12 | 3 | 75 |

| 3 | 15 | 3 | 100 |

| 1 | 3 | 4 | 50 |

| 1.5 | 4 | 4 | 50 |

| 2 | 5 | 4 | 50 |

| 2.5 | 7 | 4 | 50 |

| 3 | 8 | 4 | 50 |

| 3.5 | 10 | 4 | 50 |

| 4 | 10 | 4 | 50 |

| 4 | 16 | 4 | 75 |

| 4 | 20 | 4 | 100 |

| 5 | 13 | 5 | 50 |

| 5 | 20 | 5 | 75 |

| 5 | 25 | 5 | 100 |

| 1 | 3 | 6 | 50 |

| 1.5 | 4 | 6 | 50 |

| 2 | 5 | 6 | 50 |

| 2.5 | 7 | 6 | 50 |

| 3 | 8 | 6 | 50 |

| 3.5 | 10 | 6 | 50 |

| 4 | 10 | 6 | 50 |

| 4.5 | 12 | 6 | 50 |

| 5 | 13 | 6 | 50 |

| 5.5 | 15 | 6 | 50 |

| 6 | 15 | 6 | 50 |

| 6 | 25 | 6 | 75 |

| 6 | 30 | 6 | 100 |

| 6 | 40 | 6 | 150 |

| 7 | 18 | 8 | 60 |

| 8 | 20 | 8 | 60 |

| 8 | 28 | 8 | 75 |

| 8 | 35 | 8 | 100 |

| 8 | 50 | 8 | 150 |

| 9 | 23 | 10 | 75 |

| 10 | 25 | 10 | 75 |

| 10 | 40 | 10 | 100 |

| 10 | 50 | 10 | 150 |

| 11 | 28 | 12 | 75 |

| 12 | 30 | 12 | 75 |

| 12 | 45 | 12 | 100 |

| 12 | 60 | 12 | 150 |

| 14 | 35 | 14 | 80 |

| 13 | 45 | 14 | 100 |

| 14 | 45 | 14 | 100 |

| 14 | 60 | 14 | 150 |

| 15 | 45 | 16 | 100 |

| 16 | 45 | 16 | 100 |

| 16 | 60 | 16 | 150 |

| 18 | 45 | 18 | 100 |

| 18 | 70 | 18 | 150 |

| 20 | 45 | 20 | 100 |

| 20 | 70 | 20 | 150 |

1.Use nano-tech, the hardness and thermal stability are up to 4000HV and 1200 degree, respectively.

2. Double-edge design improves rigidity and surface finish effectively. Cutting edge over the center reduces the cutting resistance. High capacity of junk slot benefits chip removal and increases machining efficiency. 2 flutes design is good for chip removal, easy for vertical feed processing, widely used in slot and hole processing.

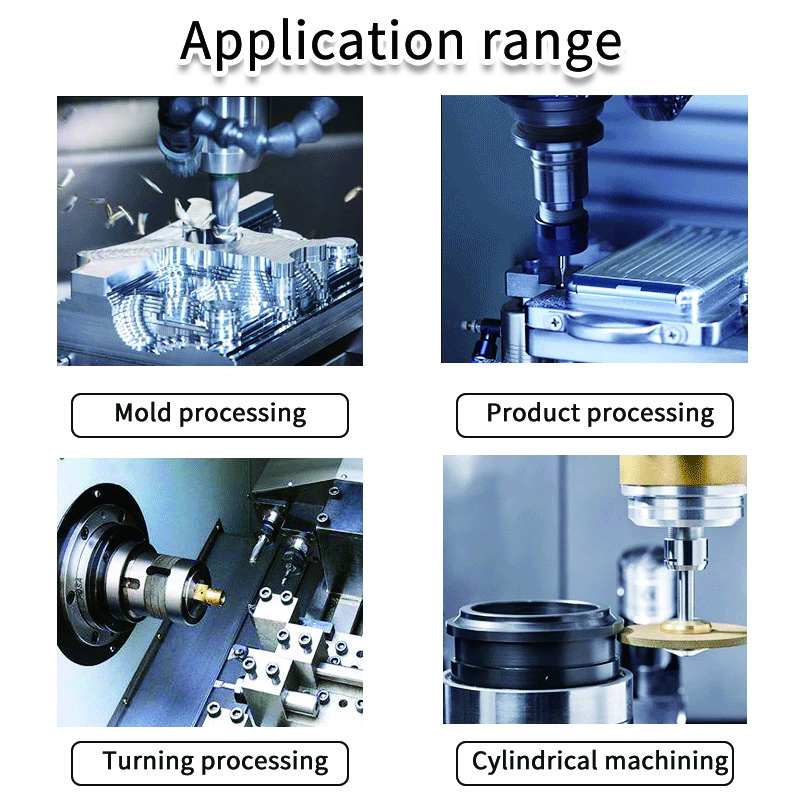

3. 4 Flutes, high rigidity, widely used in shallow slot, profile milling and finish machining.

4. 35 deg, high adaptability to the material and hardness of workpiece, widely used to mold and product processing and cost efficient.

| Type | Flat Head | Uses | Plane / side / slot / diagonal cut |

| Coating | AlTiSiN | Edge shape | Sharp angle |

| Type | Flat head type | Brand | MSK |

What customers say about us

FAQ

Q1: Who are we?

A1: MSK (Tianjin) Cutting Technology Co., Ltd. was established in 2015. It has been growing and has passed Rheinland ISO 9001

With international advanced manufacturing equipment such as SACCKE high-end five-axis grinding center in Germany, ZOLLER six-axis tool testing center in Germany, and PALMARY machine tools in Taiwan, it is committed to producing high-end, professional, efficient and durable CNC tools.

Q2: Are you trading company or manufacturer?

A2: We are manufacturer of carbide tools.

Q3: Can you send the product to our forwarder in China?

A3: Yes, if you have a forwarder in China, we are happy to send the products to him/her.

Q4: What payment terms can be accepted?

A4: Usually we accept T/T.

Q5: Do you accept OEM orders?

A5: Yes, OEM and customization are available, we also provide custom label printing service.

Q6: Why choose us?

1) Cost control - purchase high-quality products at an appropriate price.

2) Quick response - within 48 hours, professionals will provide you with quotations and solve your doubts

consider.

3) High quality - the company always proves with a sincere heart that the products it provides are 100% high-quality, so that you have no worries.

4) After-sales service and technical guidance - we will provide one-on-one customized service and technical guidance according to your requirements.

Collet chucks without drive slots: a must-have tool holder

When it comes to precision machining, having the right tool holder is essential. One such tool holder is a collet. In this blog post, we'll explore the advantages of collet chucks without drive slots, focusing on the NBT ER 30 collet chuck holders.

A collet is a tool holder that securely clamps a cutting tool in place during a machining operation. The absence of drive slots in the collet chuck has several advantages. First, because there are no drive slots, collets can accommodate longer cutting tools, allowing for deeper cuts and increased productivity. This capability makes it particularly useful in industries such as aerospace and automotive where precision is critical.

NBT ER 30 collet holders are a popular choice among machining industry professionals. It combines the advantages of a driveless collet with the precision and versatility of an ER collet. ER collet holders are known for their excellent clamping strength and high precision. With the NBT ER 30 collet you get all these advantages in one holder.

NBT ER 30 Collet Chuck Holders are designed for cylindrical shank tools with a diameter of 2-16mm. Its compact design and robust construction ensure maximum rigidity and stability during machining operations. The holder is compatible with a wide range of CNC machines, making it a versatile choice for a variety of machining applications.

In addition to superior performance, the NBT ER 30 collet chuck offers easy set-up and tool changing. This saves valuable setup time and increases productivity. The collet chuck comes with a wrench for quick and efficient tool changes, allowing the operator to focus on the task at hand.

All in all, collets without drive slots, such as NBT ER 30 collet holders, are valuable tools for precision machining. Its ability to accommodate longer cutting tools, combined with the clamping strength and precision of ER collets, make it the preferred choice of professionals in the industry. Whether you work in aerospace, automotive, or any other area of precision machining, investing in a high-quality collet chuck without drive slots can significantly improve your machining operations.