High Quality Import M35 Thread Forming Tap For Milling Machine

PRODUCT DESCRIPTION

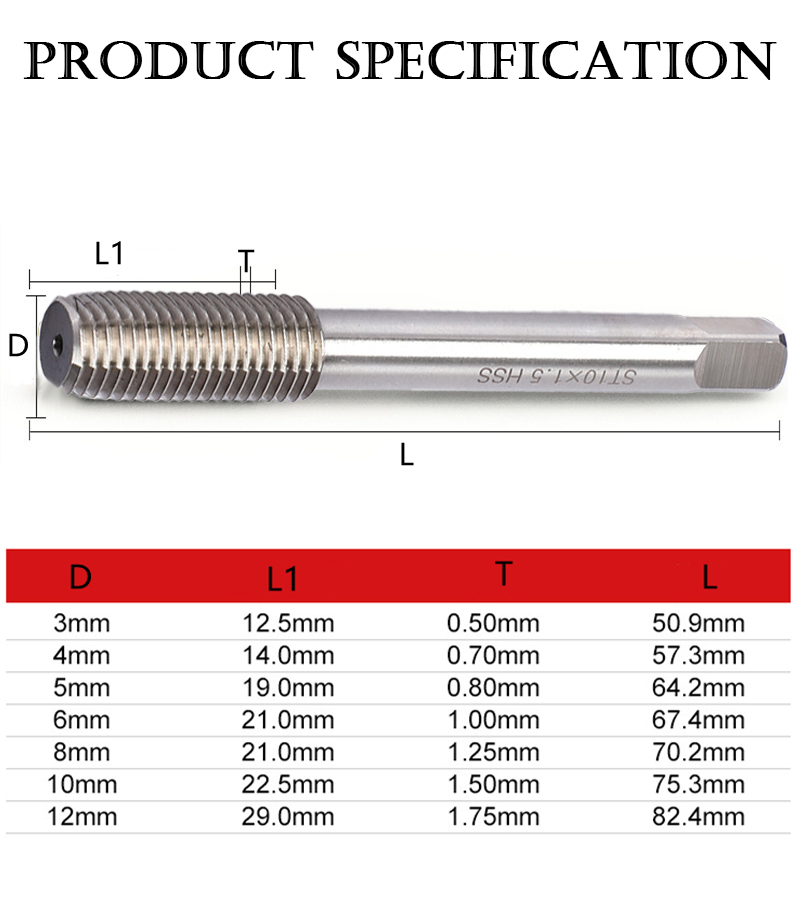

| Brand | MSK | Coating | TiN |

| MOQ | 3 PCS | Use equipment | CNC equipment, precision drilling machine |

| Material | Import M35 | Holder Type | Japanese Standard |

ADVANTAGE

Title: Improving Efficiency and Accuracy with Thread Forming Taps

introduce:

In today's fast-paced manufacturing, efficiency and precision are critical. The thread forming tap is a tool that has revolutionized the process of threading materials. This innovative tool significantly increases the reliability and durability of threaded connections compared to traditional methods. In this blog, we will explore the benefits of using thread forming taps and how they can help simplify manufacturing operations.

1. Understand the function:

Thread forming taps are essential precision tools in the machining industry. Unlike traditional taps that cut threads, thread forming taps work by reshaping material to produce threads with exceptional precision and consistency. By applying controlled pressure, the tap moves material without causing any stress concentrations. This deformation process not only strengthens the thread, but also reduces the risk of cracks or weak points in the material. As a result, businesses can rely on the resilience and longevity of threaded connections.

2. Significant advantages:

Using a thread forming tap has several advantages that make it the first choice in many applications. In addition to increasing the strength and durability of threads, these taps reduce the risk of material stripping or damage. The resulting threads have excellent resistance to vibration and loosening, making them more reliable in critical assemblies. In addition, thanks to the efficient deformation process, operators can achieve higher productivity while minimizing scrap and rework. Thread forming taps are also an environmentally friendly choice because they require less energy and produce fewer chips than traditional tapping methods.

3. Suitable applications:

Thread forming taps are used in a wide variety of industries including automotive, aerospace, plumbing and electronics. Their ability to form threads in a variety of materials, including metals, plastics and composites, contributes to their versatility. Whether machining threads in aluminum engine blocks, stainless steel fittings, or plastic housing components, thread forming taps provide consistent results. Their compatibility with different material types ensures that manufacturers can optimize their processes without compromising precision or sacrificing efficiency.

4. Best practices for best results:

To maximize the benefits of thread forming taps, industry best practices must be followed. First, selecting the correct tap geometry for the thread material is critical. This ensures proper deformation without excessive force, minimizing the risk of tool breakage or twisted threads. Precision lubrication during tapping also plays a vital role in achieving the best results. Additionally, providing adequate machine stability and maintaining proper cutting speeds will help increase the life of the tap and the overall efficiency of threading.

in conclusion:

Thread forming taps have been a game changer in manufacturing, revolutionizing the formation of threads in materials. Their ability to provide strong, reliable and precise threads while increasing efficiency makes them a workhorse tool in countless applications. The use of thread forming taps not only improves the quality of threaded connections, but also increases the overall productivity of machining operations. By adopting this innovative technology, manufacturers can maintain a leading position in a highly competitive market, while meeting strict quality standards and ensuring the durability of threaded components.