Umshini Wokugaya Ummbila We-Alloys Ezisekelwe Ku-Nickel Ezisezingeni Eliphezulu

INCAZELO YOMKHIQIZO

I-Titanium iyinto enzima kakhulu ukuyisebenzisa emshinini, ikakhulukazi ezindleleni zamathuluzi ezinamandla, njengalezo ezihlotshaniswa ne-High Efficiency Milling (HEM). Lo msiki wokugaya we-radius ekhoneni usetshenziswa ngokukhethekile ekucubungulweni kwezinto embonini yezindiza. Isebenzisa isitokwe sebha yensimbi ye-tungsten engenisiwe futhi inempilo ende yenkonzo.

ISINCOMO SOKUSENZISWA EZINDAWENI ZOKUSEBENZA

I-alloy ye-titanium TC18-21, i-ferrite, i-alloy ye-nickel ephezulu ngaphezu kwama-35%, insimbi engagqwali eshisa kakhulu, i-nickel-chromium-cobalt kanye nezinye i-alloy ze-titanium ezinamandla okunzima ukuzisika, izinto ze-alloy ezishisa kakhulu.

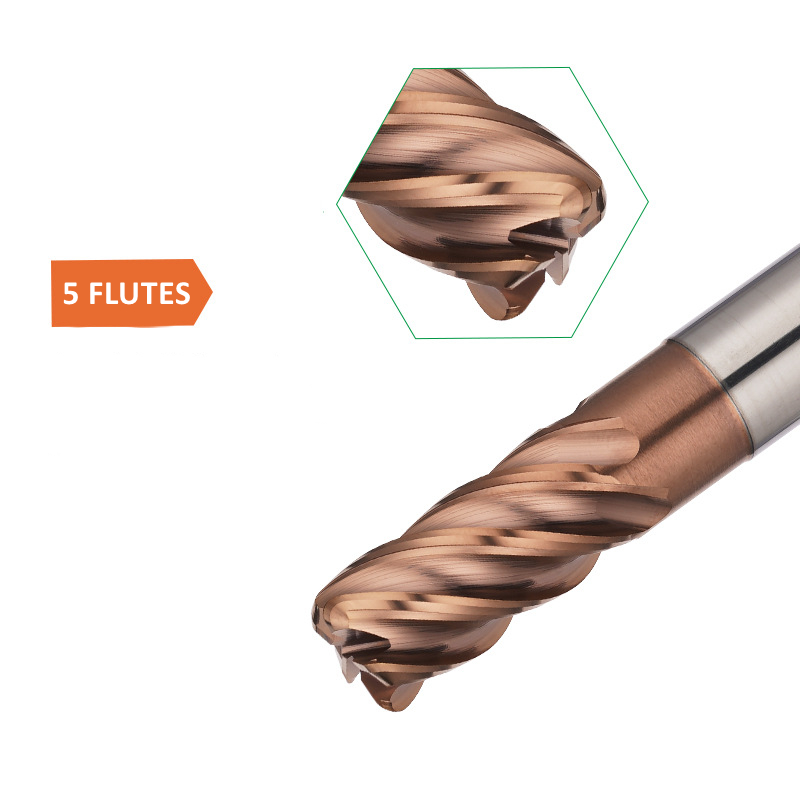

Umklamo we-5-flute ushesha ngo-30%-40% kune-3-flute/4-flute milling cutter.

Umklamo Wokuzamazama/Izinga Lokususa Insimbi Eliphezulu Kakhulu/Ukucindezeleka Kwangaphakathi Okuphansi

| Ububanzi be-Flute | D6-D12 | Ubude beFlute | 8-24mm |

| Uhlobo Lomtshingo | I-Helical | Izinto | I-tungsten yezinga eliphezulu |

| Ukugqoka | Yebo | Umkhiqizo | I-MSK |

| Ibanga Lokucubungula | Izinto okunzima ukuzisika njenge-titanium alloys, ama-superalloy, ama-ferrite, imizimba ye-nickel, izinsimbi ezingagqwali ezishisa kakhulu, kanye ne-nickel-chromium-cobalt | ||

| Imishini Esebenzayo | Imishini yokugaya, izikhungo zokugaya ze-CNC, ama-gong ekhompyutha, imishini yokuqopha | ||

Isici

1. Okukhethekile kwezinto eziqinile zokusika i-Titanium / superalloy

Ifakwe ungqimba oluphezulu lokuthambisa kanye nolwe-coefficient ephansi yokungqubuzana ukuze kuncishiswe ukucindezeleka kwangaphakathi kwezinto ezicutshungulwayo.

2. Umtshingo weJiyomethri

Umklamo omuhle kakhulu wejiyometri we-U-groove onezinsika ezi-5 ungandisa indawo yokuxhumana nezinto okufanele zicutshungulwe, ngenkathi ukhulisa ukuqina kwethuluzi futhi uqinisekisa ukuthi ubuso buqinile.

3. Ibha yensimbi ye-tungsten engenisiwe

Ukunemba kokubekezelela i-shank kwe-H5, okwenzelwe ngokukhethekile izinhlelo zokubopha i-shank ezinemba kakhulu.

4. Umklamo we-Chamfer

Yenza kube lula ukuboshwa.

5. Umklamo Wokuzamazama Komhlaba

Izinga lokususa insimbi eliphezulu kakhulu, ukucindezeleka okuphansi kwangaphakathi, ngokushesha okungu-30%-40% kunezicucu zokugaya zendabuko ezinama-blade angu-3/4

Isicelo:

Izindiza, ezempi, izingxenye zemishini, izimoto, ukuxhumana okukhethekile kwe-elekthronikhi kanye neminye imikhakha

Inothi Lomthengi:

1. Ngaphambi kokusebenzisa ithuluzi, sicela ulinganise ukuphambuka kwethuluzi. Uma ukunemba kokuphambuka kwethuluzi kudlula u-0.01mm, sicela ukulungise ngaphambi kokusika.

2. Uma ubude bethuluzi bufushane buphuma ebhodweni, kungcono. Uma ithuluzi liphuma isikhathi eside, isivinini, izinga lokuphakelwa kanye nenani lokusika kudingeka kuncishiswe.

3. Ngesikhathi sokusika, uma kuvela ukudlidliza noma umsindo ongavamile, sicela wehlise isivinini kanye nenani lokusika kuze kube yilapho isimo sithuthuka.

4. Ukupholisa insimbi kungcono kube yi-spray kanye ne-air jet, okungathuthukisa umphumela wokusetshenziswa kwe-milling cutter. Ama-alloy e-titanium namanye ama-superalloy awanconywa.