I-Corn Radius Mill yee-alloys ze-Nickel ezisekelwe kwi-High-Temp

INGCACISO YEMVELISO

I-Titanium yinto enzima kakhulu ukuyisebenzisa ngomatshini, ingakumbi kwiindlela zezixhobo ezinamandla, ezifana nezo zinxulunyaniswa ne-High Efficiency Milling (HEM). Le corner radius milling cutter isetyenziselwa ngokukodwa ukucubungula izinto kwishishini leenqwelo moya. Isebenzisa i-tungsten steel bar stock evela kwamanye amazwe kwaye inobomi obude benkonzo.

INGCEBISO YOKUSETYENZISWA KWII-WORKSHOP

I-alloy yeTitanium TC18-21, i-ferrite, i-alloy ye-nickel ephezulu engaphezulu kwama-35%, intsimbi engatyiwayo enobushushu obuphezulu, i-nickel-chromium-cobalt kunye nezinye ii-alloy ze-titanium ezinamandla aphezulu ezinzima ukuzisika, izixhobo ze-alloy ezinobushushu obuphezulu.

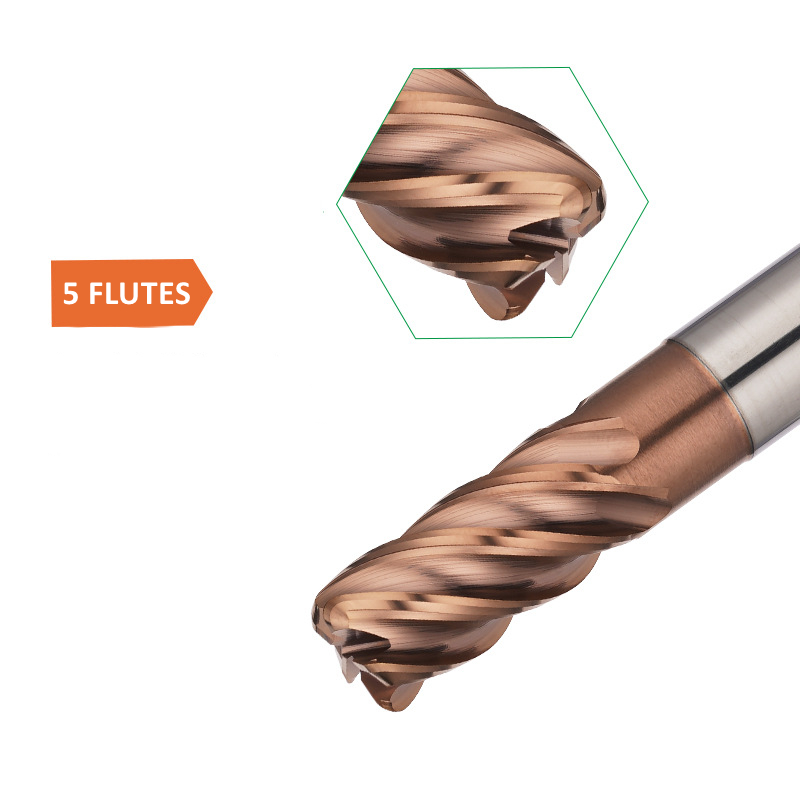

Uyilo lweflute ezi-5 lukhawuleza ngama-30%-40% kune-3-flute/4-flute milling cutter.

Uyilo lweNyikima/Izinga lokususa isinyithi eliPhezulu/Uxinzelelo lwangaphakathi oluphantsi

| Ububanzi beFlute | D6-D12 | Ubude beFlute | 8-24mm |

| Uhlobo lweFlute | I-Helical | Izinto eziphathekayo | I-tungsten yodidi oluphezulu |

| Ukwaleka | Ewe | Uphawu | I-MSK |

| Uluhlu Lokucubungula | Izinto ezinzima ukuzisika ezifana nee-alloys ze-titanium, ii-superalloys, ii-ferrites, imizimba ye-nickel, iintsimbi ezingenasici ezishushu kakhulu, kunye ne-nickel-chromium-cobalt | ||

| Oomatshini Abasebenzayo | Oomatshini bokugaya, amaziko oomatshini be-CNC, iigong zekhompyutha, oomatshini bokukrola | ||

IMBONAKALO

1.Ikhethekileyo kwiTitanium / superalloy izinto ezinzima ukunqunyulwa

Ixhotyiswe nge-lubricating coefficient coefficient ephezulu kunye ne-friction coefficient ephantsi ukunciphisa uxinzelelo lwangaphakathi lwezinto ezicutshungulwayo.

2. I-Flute yeJiyometri

Uyilo oluhle kakhulu lwejometri ye-U-groove enamabala ama-5 lunokwandisa indawo yokudibana nezinto eziza kucutshungulwa, ngelixa lunyusa ukuqina kwesixhobo kwaye luqinisekisa ukuba umphezulu urhabaxa.

3. Ibha yentsimbi ye-tungsten engenisiweyo

Ukuchaneka kokunyamezelana kwe-shank kwe-H5, eyenzelwe ngokukodwa iinkqubo zokubambelela kwe-shank ezichanekileyo kakhulu.

4. Uyilo lweChamfer

Yenza kube lula ukubotshwa.

5. Uyilo lweNyikima

Izinga lokususa isinyithi eliphezulu kakhulu, uxinzelelo oluphantsi lwangaphakathi, ngokukhawuleza ngama-30%-40% kunezixhobo zokusika zemveli ezineeblade ezi-3/4

Isicelo:

I-Aerospace, imikhosi, iindawo zoomatshini, iimoto, unxibelelwano olukhethekileyo lwe-elektroniki kunye nezinye iinkalo

Inqaku lomthengi:

1. Ngaphambi kokusebenzisa isixhobo, nceda ulinganise ukuphambuka kwesixhobo. Xa ukuchaneka kokuphambuka kwesixhobo kudlula i-0.01mm, nceda ulungise ngaphambi kokuba usike.

2. Okukhona ubude besixhobo bufutshane buphuma kwi-chuck, kokukhona kungcono. Ukuba isixhobo siphuma ixesha elide, isantya, isantya sokutya kunye nobungakanani bokusika kufuneka kuncitshiswe.

3. Ngexesha lokusika, ukuba kukho ukungcangcazela okungaqhelekanga okanye isandi, nceda wehlise isantya kunye nobungakanani bokusika de imeko iphucuke.

4. Ukupholisa intsimbi kungcono kukusetyenziswa njenge-spray kunye ne-air jet, nto leyo enokuphucula isiphumo sokusetyenziswa kwe-milling cutter. Ii-alloys ze-titanium kunye nezinye ii-superalloys azikhuthazwa.