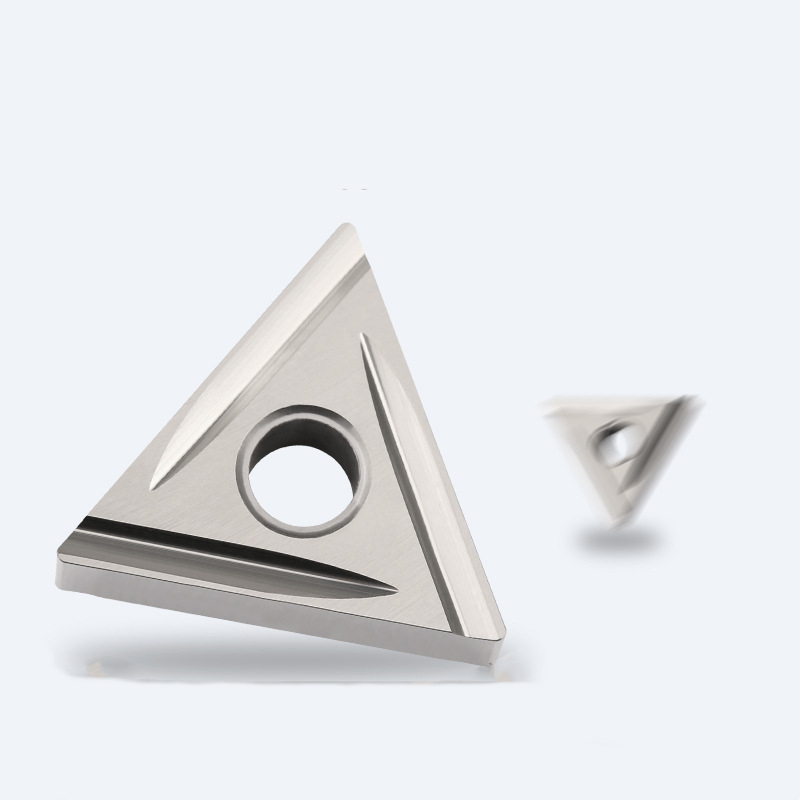

Izifakelo zeCermet ezisemgangathweni olungileyo zokuGqibezela iNsimbi kunye neStainless

INGCACISO YEMVELISO

Ngasekugqibeleni kwempompo (umbhobho wentambo) kukho i-drill bit, eyi-tap esebenza kakuhle kakhulu (umbhobho wentambo) yokubhola rhoqo kunye nokucofa ukuze kugqitywe ukucutshungulwa ngaxeshanye.

Iimbonakalo

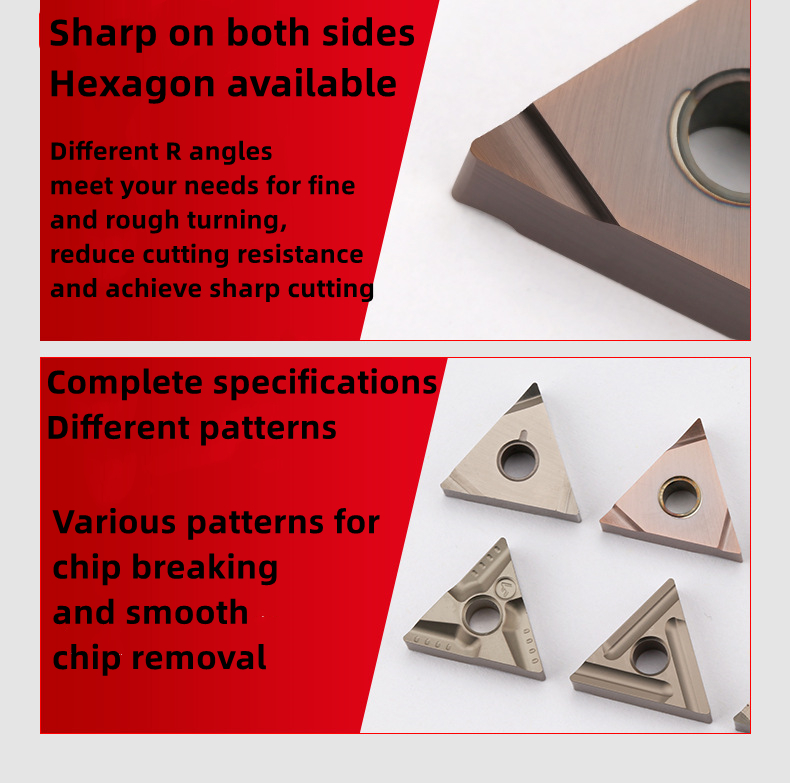

1. Ibukhali enamacala amabini, iHexagon iyafumaneka

Ii-engile ezahlukeneyo ze-R ziyahlangabezana neemfuno zakho zokujika kakuhle nangokurhabaxa, Yehlisa ukumelana nokusika kwaye ufezekise ukusika okubukhali

2. Iipateni ezahlukeneyo

Iinkcukacha ezipheleleyo kunye neepateni ezahlukeneyo zokuqhekeza iitshiphusi kunye nokususa iitshiphusi ngokutyibilikayo

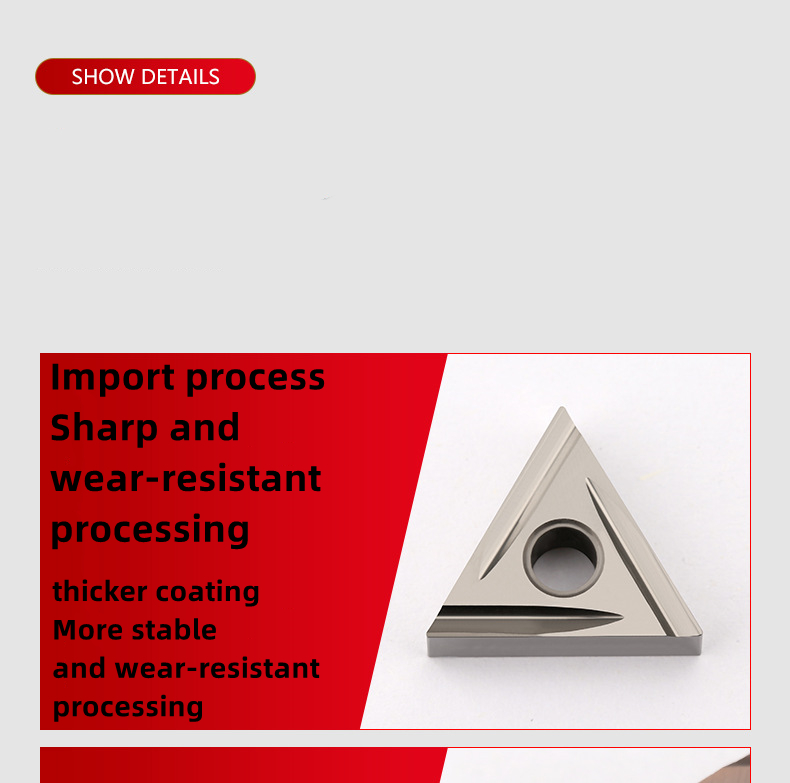

3. Inkqubo yokungenisa

Ingubo ebukhali nengagugiyo, etyebileyo.

Ukucubungula okuzinzileyo ngakumbi nokungagugiyo

Ikhethekileyo kwiiseramikhi, ayigugi kwaye ihlala ixesha elide, kwaye inobunzima obuphezulu.

| Uphawu | I-MSK | Uhlobo | Isixhobo sokuMila |

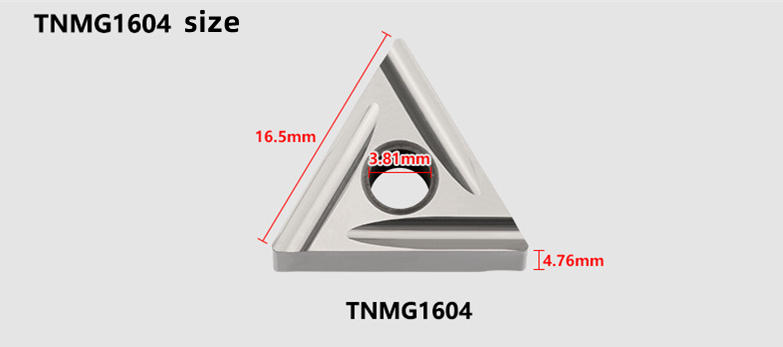

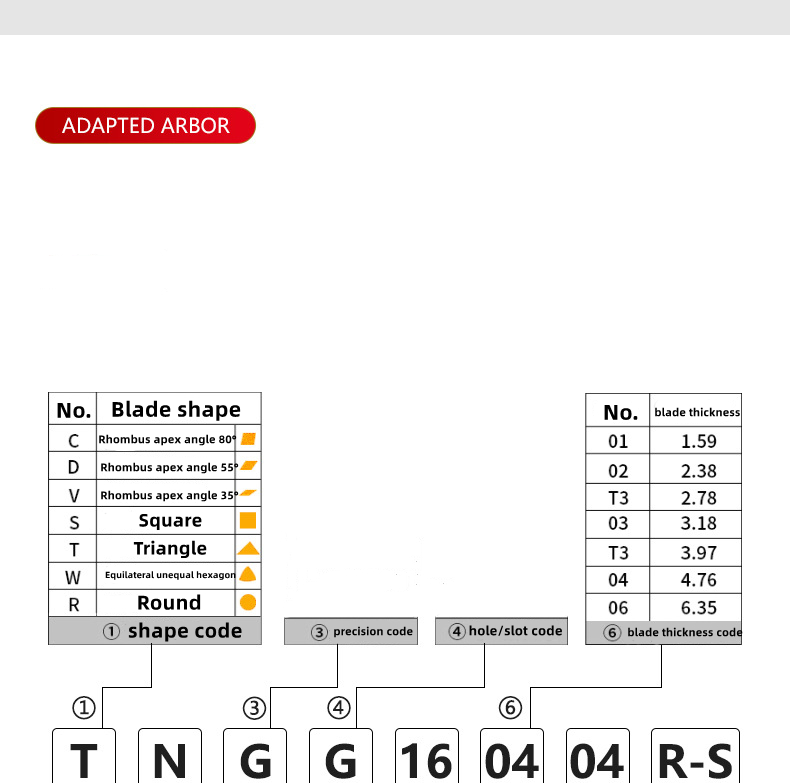

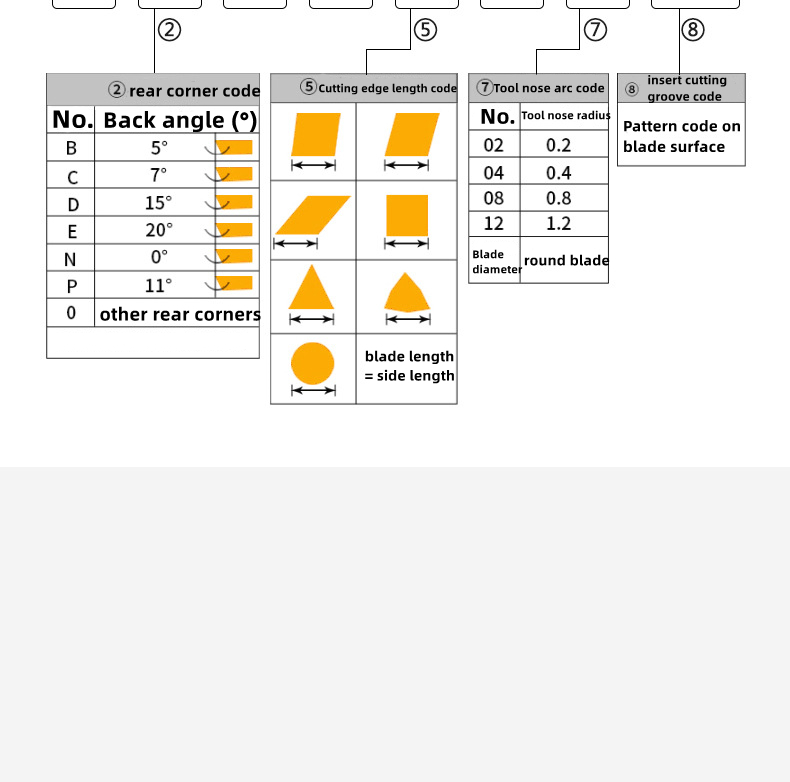

| Igama lemveliso | Izinto zokufaka iiCarbide | Imodeli | TNGG160402 |

| Izinto eziphathekayo | Iiseramikhi | Iphakheji | Ibhokisi yeplastiki |

ISAZISO

Uhlalutyo lweengxaki eziqhelekileyo

1. Ukuguguleka kobuso ngerake: (le yindlela eqhelekileyo yokusebenza)

Iziphumo: Utshintsho oluncinci kancinci kubungakanani bezinto zokusebenza okanye ukugqitywa komphezulu okunciphileyo.

Isizathu: Izinto zeblade azifanelekanga, kwaye ubungakanani bokusika bukhulu kakhulu.

Iindlela zokulinganisa: Khetha into eqinileyo, nciphisa ubungakanani bokusika, kwaye unciphise isantya sokusika.

2. Ingxaki yokuphahlazeka: (uhlobo olubi lokusebenza)

Iziphumo: Utshintsho olukhawulezileyo kubungakanani bezinto zokusebenza okanye ukugqitywa komphezulu, okubangela ukuba kubekho ii-sparkle surface burrs.

Isizathu: ukuseta iiparameter ezingafanelekanga, ukukhetha okungafanelekanga kwezinto zeblade, ubulukhuni obungalunganga bento yokusebenza, ukubamba iiblade okungazinzanga. Isenzo: Jonga iiparameter zomatshini, ezinje ngokunciphisa isantya somgca kunye nokutshintsha ukuya kwindawo ephezulu enganyangekiyo.

3. Iphukile kakhulu: (uhlobo olubi kakhulu lokusebenza)

Impembelelo: ukwenzeka ngequbuliso nokungalindelekanga, okubangela ukuba izixhobo ezibambe isixhobo zilahlwe okanye umsebenzi onesiphako uze ulahlwe. Isizathu: Iiparameter zokucubungula zibekwe ngendlela engafanelekanga, kwaye umsebenzi wesixhobo sokungcangcazela okanye iblade awufakwanga endaweni yawo.

Amanyathelo: Misela iiparameter ezifanelekileyo zoomatshini bokugaya, nciphisa izinga lokutya kwaye unciphise iitships ukuze ukhethe izixhobo zokugaya ezifanelekileyo.

Qinisekisa ubungqongqo bento yokusebenza kunye neblade.

3. Umphetho owakhelwe phezulu

Impembelelo: Ubungakanani besixhobo sokusebenza esiphumayo abuhambelani, umphezulu womsebenzi awulunganga, kwaye umphezulu wesixhobo sokusebenza unamatheliswe ngefluff okanye iiburrs. Isizathu: Isantya sokusika siphantsi kakhulu, ukutya kuphantsi kakhulu kwaye iblade ayibukhali ngokwaneleyo.

Amanyathelo: Yandisa isantya sokusika kwaye usebenzise i-insert ebukhali kwisondlo.