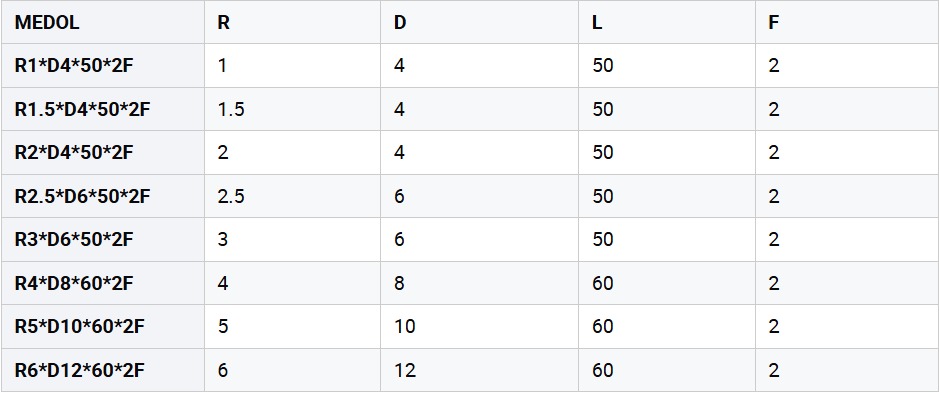

T-Type Circular End Mill

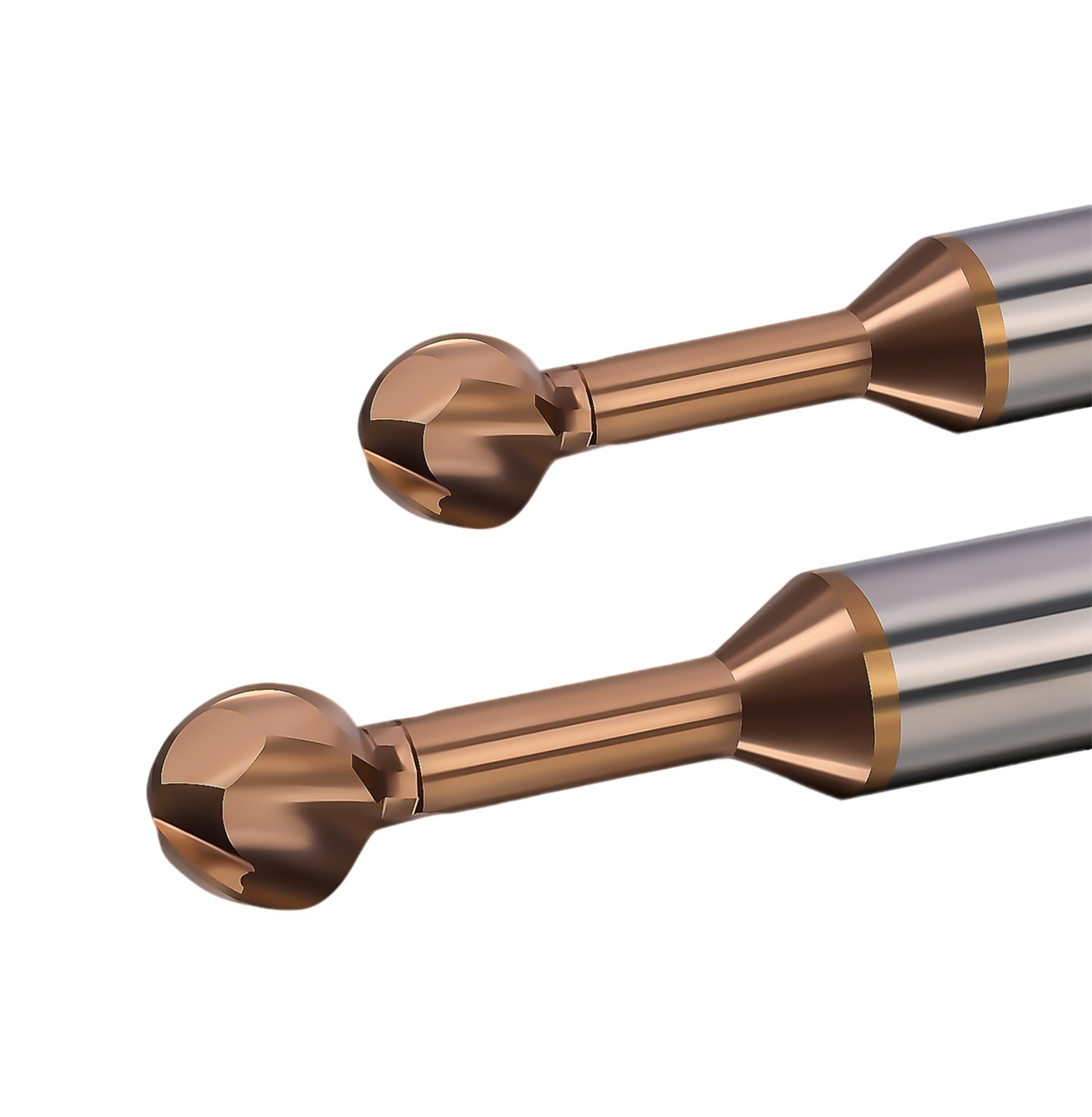

This hard alloy ball-end milling cutter features a high-hardness base and nano-coating, combined with a long straight shank design. It maintains excellent red hardness and anti-chipping properties during high-speed cutting. Its widened chip-removal grooves and balanced edge design ensure efficient chip removal and smooth machining, significantly enhancing the semi-finishing and finishing efficiency and surface quality for materials such as mold steel and stainless steel.

Important Attributes

| Coating | Silicon Titanium Nitride | HRC | Super-hard |

| Material | Carbide | Support customization | OEM |

| Applicable Machines | Horizontal Milling Machine, Vertical Milling Machine |

Cutting direction | Conventional milling |

| Cutting Edge Length | 10mm | Place of Origin | Tianjin, China |

| Model | MSKDT | Brand | MSK |

| Cutting Hardness | hrc45, hrc50, hrc55 | Effective cutting length | / |

| Groove Type | 2 flutes | Spiral angle | / |

| Warranty Period | 3 months | Product Name | Sticky candy end mill |

| Application | CNC Milling | Flute | 2 |

| Usage Method | CNC Machine Tool Center | Color | Metallic color |

| Keywords | Carbide Ball End Mill | Packaging | 1 piece per plastic box |

| Advantages | Sharp Cutting Edge | Processing type | Metal cutting tools |

| Minimum Order Quantity | 10 pieces | ||

Product Features

Advantages

1. Superior Durability and Stability

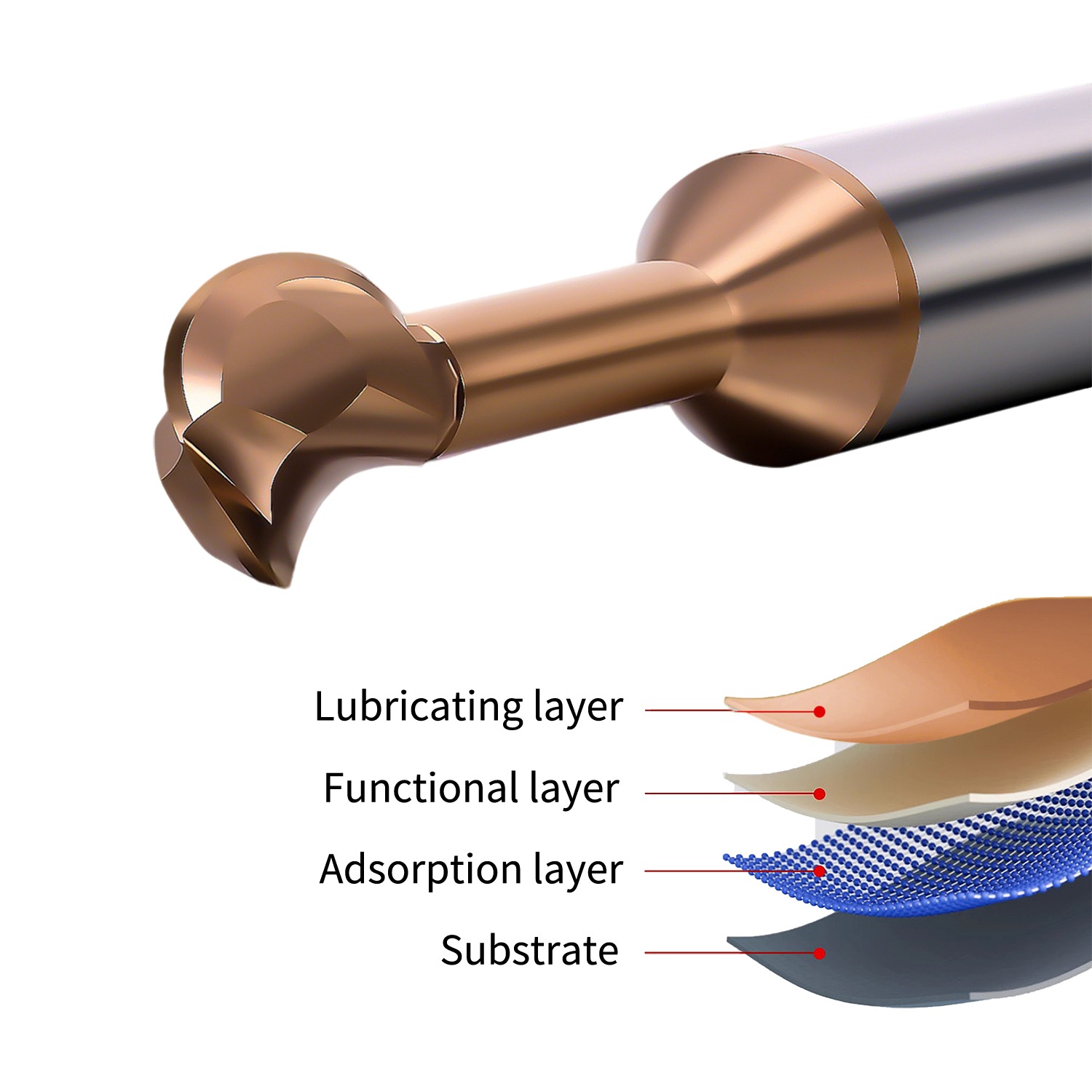

High-Hardness Substrate and Nano-Coating: Utilizing a high-hardness cemented carbide substrate combined with advanced nano-coating technology, the tool maintains excellent red hardness (high-temperature hardness) even under the high temperatures generated by high-speed cutting, effectively resisting thermal wear and extending tool life.

Strong and Impact-Resistant: Optimized design and material combination endow the tool with higher rigidity and impact resistance, effectively preventing chipping during interrupted cutting or machining of hard materials, ensuring safe and reliable machining processes.

2. Highly Efficient Cutting and Chip Removal Performance

Wide Chip Groove Design: Larger chip removal space effectively prevents chip accumulation and chip adhesion to the tool, reducing increased cutting resistance or edge damage caused by poor chip removal, thereby significantly improving production efficiency and continuity.

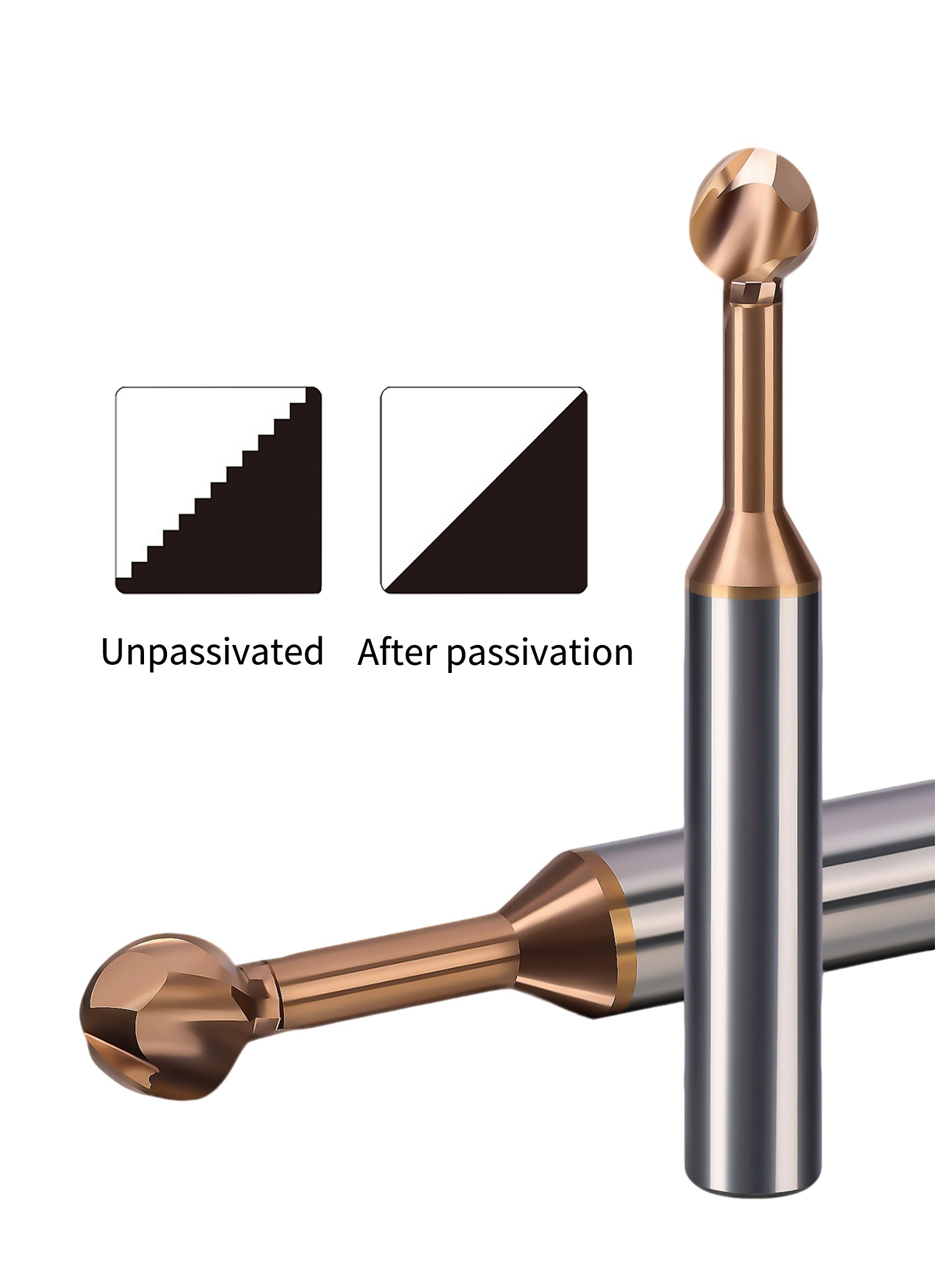

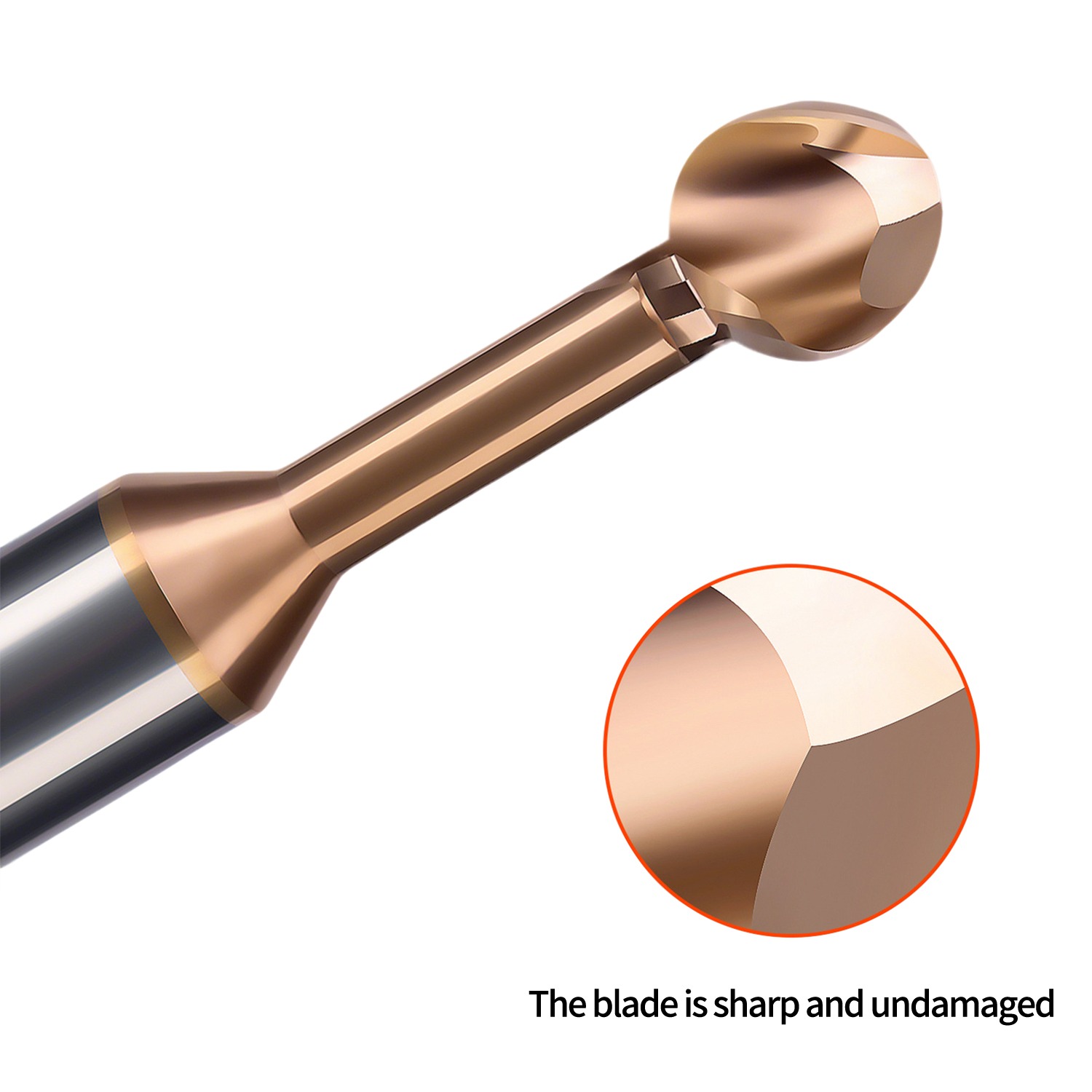

Sharp and Wear-Resistant Cutting Edge: Through precision grinding, the cutting edge strength and sharpness are balanced for smoother cutting. The cutting edge is also treated to eliminate burrs, ensuring light and precise cutting.

3. Superior Machining Quality and Precision

Smooth Surface Finishing: The tool enables smooth circumferential cutting, achieving a smooth surface finish on the working surface. It is particularly suitable for semi-finishing and finishing of materials such as mold steel and stainless steel, reducing subsequent polishing processes.

Stable Clamping and Vibration Control: The extended straight shank design ensures more stable clamping on vertical machining centers or CNC milling machines, enhancing system rigidity, reducing vibration, and further improving machining accuracy and consistency.

4. Wide Applicability and Convenience

Multi-Material Compatibility: Suitable for various difficult-to-machine materials such as mold steel and stainless steel, balancing versatility and specialization.

Standard Packaging and Fast Delivery: The product uses standardized packaging for easy storage and transportation, suitable for rapid supply chain response, ensuring user production needs are met.

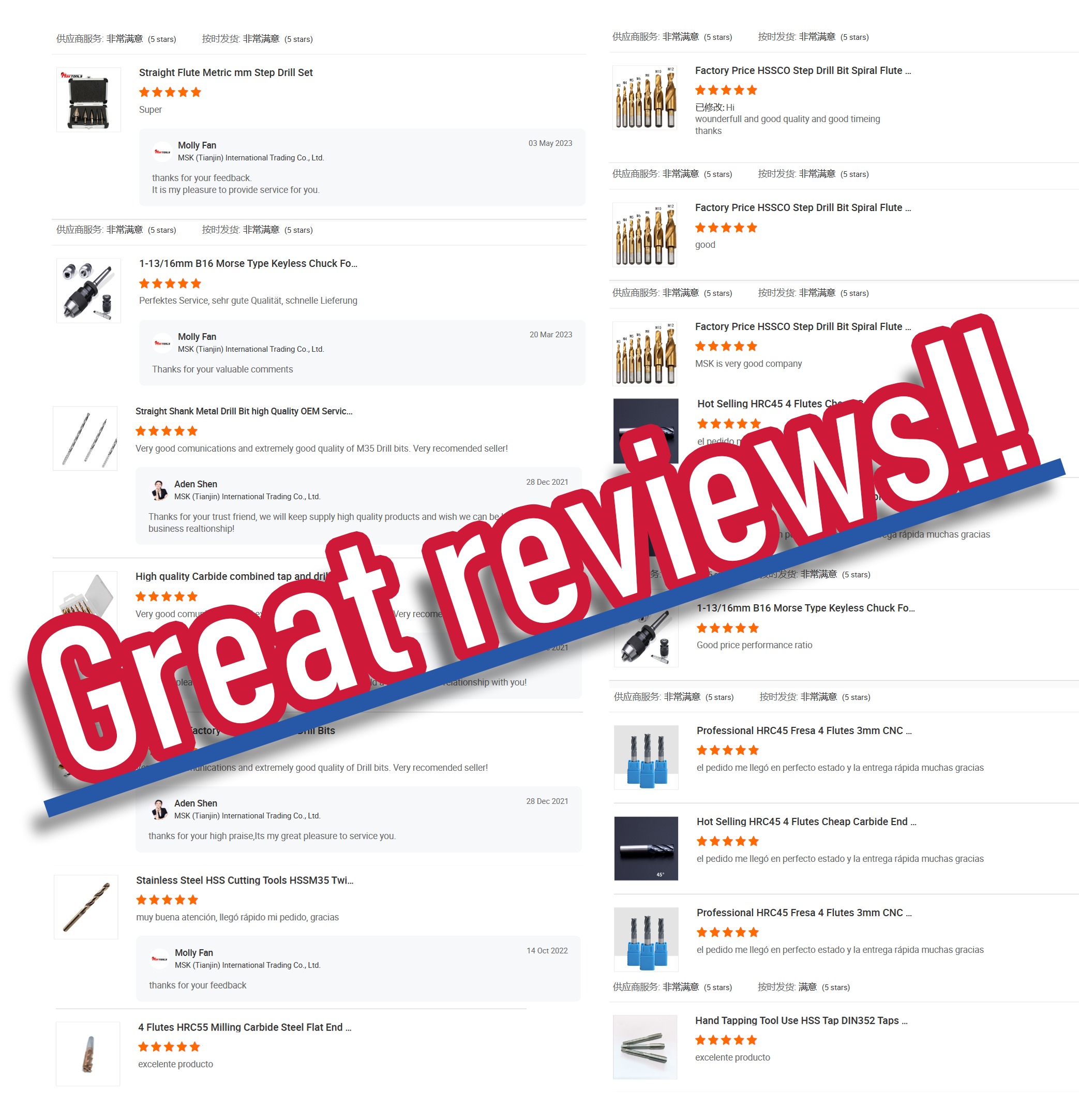

Why Choose Us

Factory Profile

FAQS

Q1.What are the advantages of this ball-end milling cutter with a nano-coating and a high-hardness base?

A:By combining a high-hardness base with a nano-coating, the cutting tool's red hardness (i.e., the ability to maintain hardness under high-speed cutting and high temperatures) has been significantly enhanced, while the wear resistance has also been improved. The coating can effectively prevent chip breakage, ensuring the stability of the cutting tool during long-term high-speed machining, especially for difficult-to-machine materials such as mold steel and stainless steel.

Q2.How does the elongated straight handle design assist in processing?

A:The elongated straight handle design provides a more stable clamping force, reduces vibration during processing, and ensures machining accuracy. It is compatible with both vertical machining centers and CNC lathes, and is particularly suitable for semi-finishing and finishing of deep cavities or complex contours, effectively enhancing the surface finish of the processed parts.

Q3.How can cutting tools avoid problems such as chip adhesion and blade fracture?

A:By designing wider chip-removal grooves, the cutting tools have a larger chip-removal space, which can quickly discharge the chips and prevent the accumulation of chips from causing chip adhesion, blade fracture or overheating of the tool. Combined with balanced edge strength and sharpness, it further reduces the generation of burrs and improves processing efficiency and tool lifespan.

Q4.Which materials is this milling cutter suitable for processing?

A:It is specially designed for high-hardness materials, particularly suitable for difficult-to-machine materials such as mold steel and stainless steel. Its high rigidity, impact resistance and wear resistance enable it to achieve smooth surface quality during semi-finishing and finishing processes, while maintaining high milling efficiency.

Q5.How can cutting tools achieve higher milling efficiency and surface quality?

A:By optimizing the edge design (balancing strength and sharpness), enhancing the rigidity of the tool, and combining with smooth circumferential cutting capabilities, the tool operates with minimal vibration and smoother cutting during processing. Widening the chip removal grooves prevents chip interference, and the nano coating reduces wear, thereby jointly improving processing efficiency, surface finish, and overall quality.