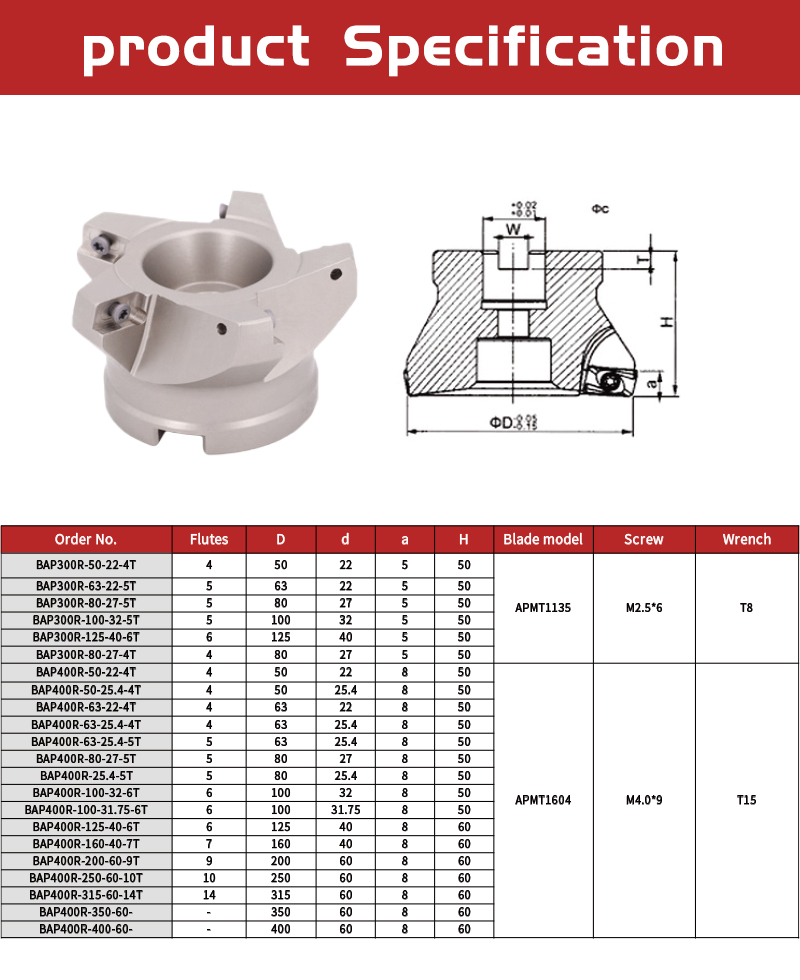

Source CNC Tool BAP400R-200-60-9T Face Milling Cutter Insert Type

| Brand | MSK | Packing | Plastic box or other |

| MOQ | 10 PCS | Usage | Cnc Milling Machine Lathe |

| Flute | 4-12 | Type | BAP300R-50-22-4T |

| Warranty | 3 months | Customized support | OEM,ODM |

Face milling is a widely used machining process in which a multi-tooth milling cutter is used to remove material from the surface of a workpiece. One of the key components of the process is the face milling cutter. Face milling cutters are versatile tools used in a variety of applications in industries such as automotive, aerospace and manufacturing.

The insert type of a face mill is an important consideration. Different insert types are designed for specific materials and cutting conditions. Some common insert types include solid carbide, indexable carbide, and high-speed steel. Each insert type has its own advantages and can significantly affect the performance of a face mill.

When selecting a face mill, it is important to consider the material of the tool itself. It is recommended to use tools that match the workpiece material. For example, if the workpiece is made of stainless steel, a face mill with high-speed steel or carbide inserts is suitable. The material of the knife plays an important role in determining the durability, performance and life of the knife.

Another important component of the face milling process is the face milling cutter shaft. The mandrel is responsible for holding the face mill firmly in place during the cutting operation. It is critical to select an arbor that matches the exact dimensions and specifications of the milling cutter to ensure a precise and stable cutting process.

Inserts used in face mills can vary in design and composition. Different insert designs provide unique cutting characteristics such as smoother cutting, reduced vibration and improved chip evacuation. Inserts made of different materials such as carbide, cermet or ceramic also affect the performance and life of the tool.

In conclusion, face milling is a versatile machining process that requires careful consideration of various factors to ensure optimum performance. Insert type, tool material, arbor and insert selection play a vital role in achieving a precise and efficient face milling operation. Manufacturers and machining professionals should carefully analyze their specific requirements and select the best face milling cutter for their application.