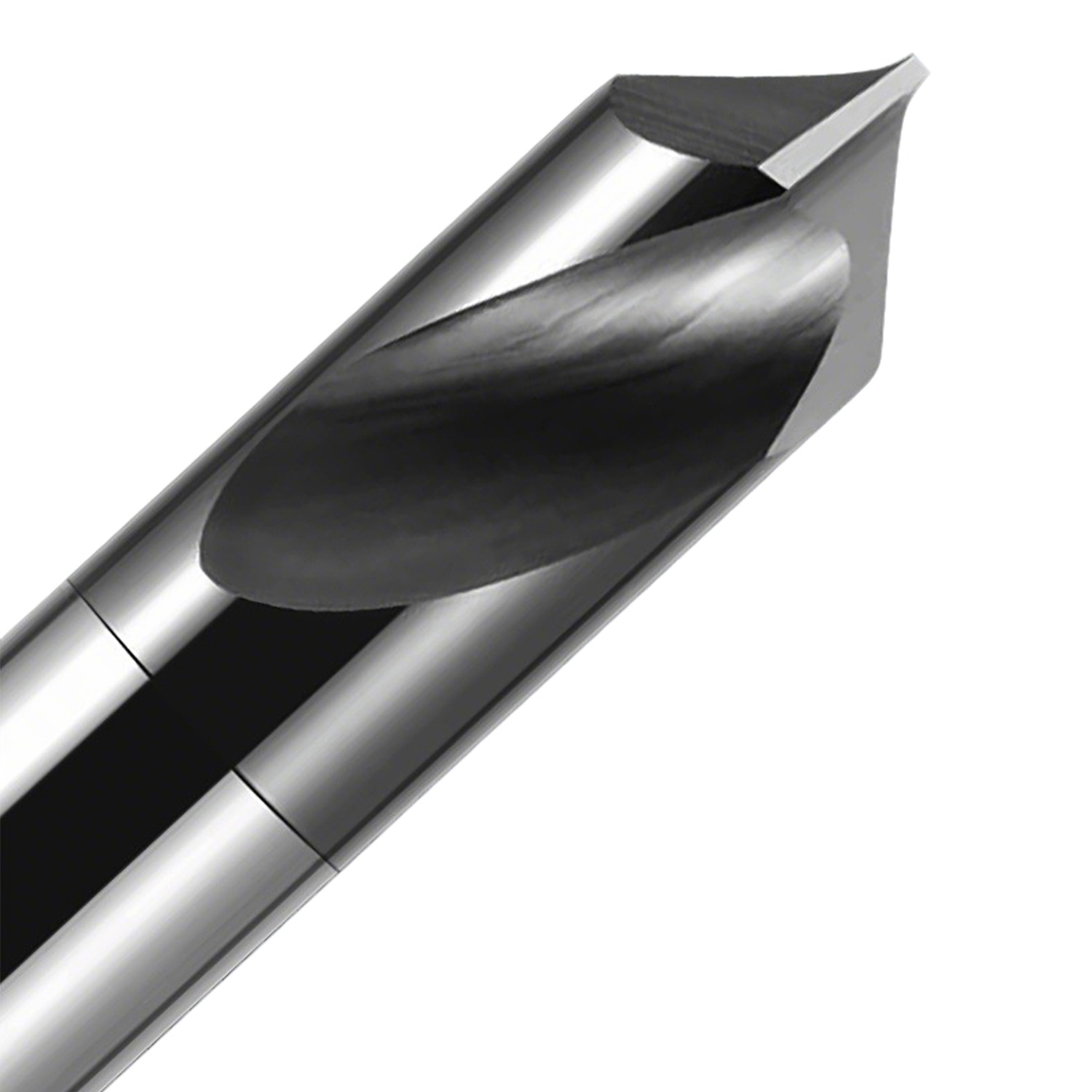

Solid Carbide Spot Drill Bit

This premium solid carbide 90° spot drill expertly combines center drilling, spotting, and chamfering in one tool. Its robust 2-flute design, enhanced by a larger core diameter, provides exceptional rigidity and vibration resistance for smooth, precise cuts. Manufactured with five-axis grinding on HRC45 carbide, it delivers superior accuracy and durability for demanding applications.

Important Attributes

| Material | Carbide | Hardness | Tungsten Steel |

| Shank Diameter | 3-12 | Total Length | 50-75 |

| place of origin | Tianjin, China | point angle | 90° |

| Surface Finishing | ALTIN Black Coating | Applications | centering/positioning, Drilling |

| Brand Name | MSK | Model Number | 3-12 |

| warranty | 3 MONTHS | customized support | OEM |

| Coating Type | ALTIN Black Coating | Number of cutting edges | 2 |

| Package Quantity | 1 | Precision | / |

| Suitable material | stainless steel and aluminum | Type | / |

| Product Name | solid carbide drill bit hrc45 | Application | Metal Drilling |

| Suitable for | Cooper.Cast Iron.Carbon Steel.Mould Steel | Flute | 2 |

| Type | Spot Drill Bit | MOQ | 10 Pieces |

| Packing | 1ps/ Plastic Box | TRANSPORT | Express |

| Color | Metal Color | Keywords | 90 Degree Spot Drill |

|

Model

|

D

|

d

|

L

|

Angle

|

|

Aluminum: Ф3x3Dx50L-90°

|

Ф3

|

3D

|

50L

|

90°

|

|

Aluminum: Ф4x4Dx50L-90°

|

Ф4

|

4D

|

50L

|

90°

|

|

Aluminum: Ф5x5Dx50L-90°

|

Ф5

|

5D

|

50L

|

90°

|

|

Aluminum: Ф6x6Dx50L-90°

|

Ф6

|

6D

|

50L

|

90°

|

|

Aluminum: Ф8x8Dx60L-90°

|

Ф8

|

8D

|

60L

|

90°

|

|

Aluminum: Ф10x10Dx75L-90°

|

Ф10

|

10D

|

75L

|

90°

|

|

Aluminum: Ф12x12Dx75L-90°

|

Ф12

|

12D

|

75L

|

90°

|

|

Steel: Ф3x3Dx50L-90°

|

Ф3

|

3D

|

50L

|

90°

|

|

Steel: Ф4x4Dx50L-90°

|

Ф4

|

4D

|

50L

|

90°

|

|

Steel: Ф5x5Dx50L-90°

|

Ф5

|

5D

|

50L

|

90°

|

|

Steel: Ф6x6Dx50L-90°

|

Ф6

|

6D

|

50L

|

90°

|

|

Steel: Ф8x8Dx60L-90°

|

Ф8

|

8D

|

60L

|

90°

|

|

Steel: Ф10x10Dx75L-90°

|

Ф10

|

10D

|

75L

|

90°

|

|

Steel: Ф12x12Dx75L-90°

|

Ф12

|

12D

|

75L

|

90°

|

Product Features

Sharp cutting edge for smooth cuttin

Advantages

1.One drill with dual functions, highly efficient and precise

The 90-degree drill tip angle integrates the functions of center drill positioning and chamfering. With a single operation, it can complete high-precision centering and perfect chamfering, reducing tool change time and improving processing efficiency and positional accuracy.

2. Excellent rigidity, stable seismic resistance

With a large core diameter design, it ensures sufficient chip-discharging space while significantly enhancing the overall rigidity and anti-vibration performance of the tool. This effectively suppresses processing vibrations, reduces the risk of chipping, and ensures stable performance even in deep holes or high-load conditions.

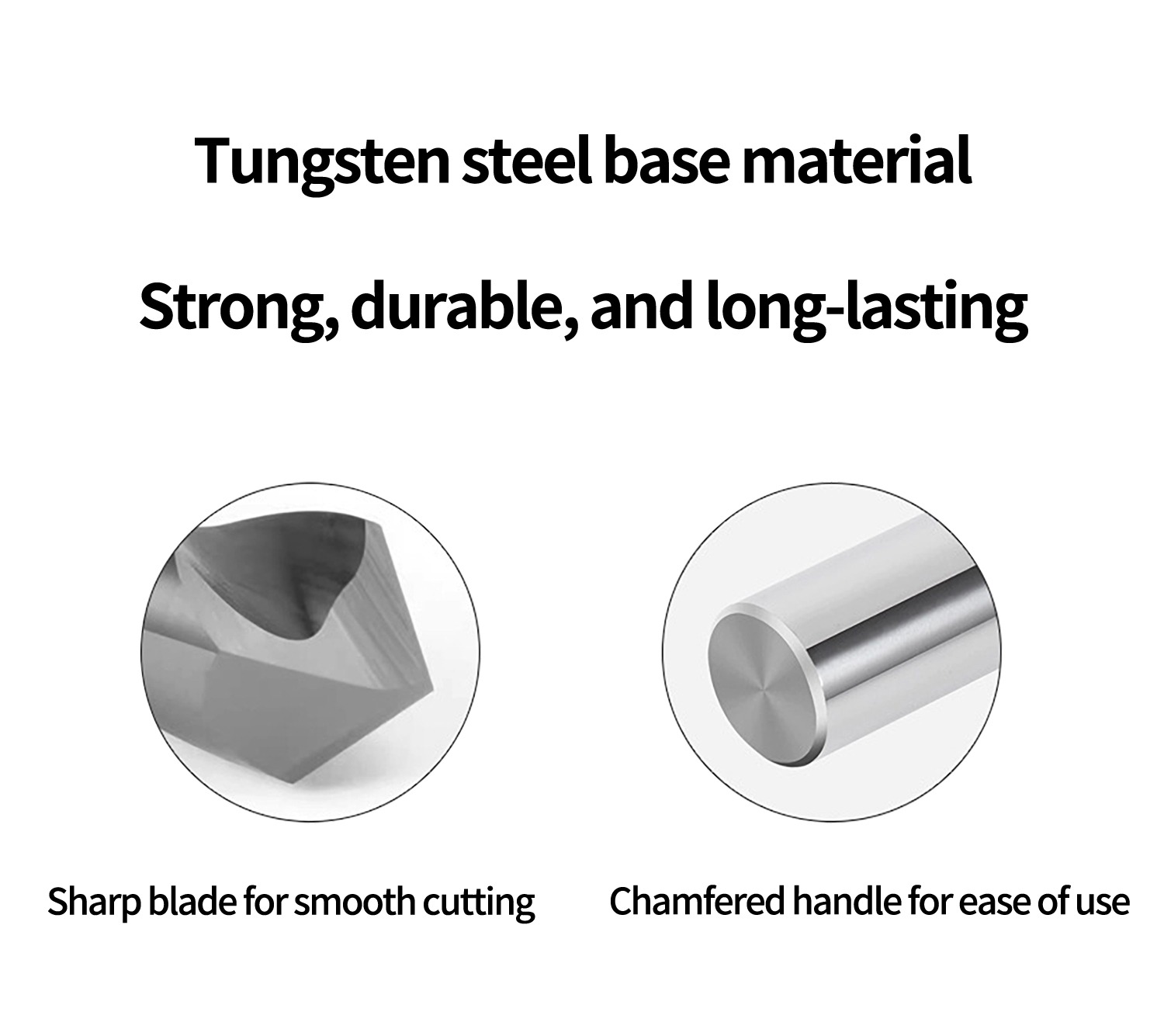

3. Super-hard and durable, long-lasting

Using high-quality hard alloy materials, the hardness reaches HRC45, featuring excellent wear resistance and impact toughness. The blade has a long service life, capable of handling continuous production, and reducing the cost of single-piece processing.

4. Sharp cutting edge, smooth processing

Precision manufacturing is carried out using a five-axis grinding machine to ensure that the cutting edge is extremely sharp and the edge is uniform. The double-edge design facilitates smooth chip removal, enabling smoother cutting and better surface finish, thereby reducing subsequent processing steps.

5. Highly versatile and stable, reliable

The standard 90-degree angle is applicable to most common chamfering and centering requirements. It is a high-reliability and wide-scope general-purpose efficient drilling tool that can simplify the inventory and management of cutting tools.

Why Choose Us

Factory Profile

FAQS

1. Q: What are the main functions and applicable scenarios of this 90-degree point drill?

A: This hard alloy point drill integrates center drill, point drill and 90-degree chamfering functions. Its precise 90-degree angle design is specifically designed for accurately locating the center of the hole, creating guiding holes, and processing high-precision chamfers before turning or milling operations. It is a key tool for achieving efficient and accurate hole processing preparations.

2. Q: What does the term "HRC45 hardness" mentioned in the product description mean?

A: HRC45 indicates that the hardness of the tool body reaches 45 degrees on the Rockwell hardness scale. For hard alloy tools, a high base hardness is the fundamental guarantee for wear resistance and service life. This ensures that the point drill can resist wear during continuous processing, maintain dimensional stability and sharpness, and achieve long-term high-performance machining.

3. Q: How does "five-axis grinding machine processing" specifically enhance the performance of the cutting tools?

A: The five-axis grinding machine process achieves ultra-high precision for the edge formation and the grinding of complex geometric structures. This directly results in sharper cutting edges, thereby achieving smoother cutting surfaces and lower cutting resistance. At the same time, the unparalleled precision ensures the consistency and repeatability of each tool angle.

4. Q: How does the "large core diameter design" of the cutting tool ensure both rigidity and chip removal space?

A: We have achieved a large core diameter between the double-edge grooves through optimized design. This structure significantly enhances the overall rigidity and anti-vibration performance of the cutting tool, reduces the risk of fracture, and at the same time provides a smooth chip removal channel, effectively avoiding the common chip blockage problem that occurs during deep hole drilling.

5. Q: Compared to ordinary high-speed steel or cheap carbide point drills, where does this product's core advantage lie?

A: The core advantage lies in the combination of "high-performance carbide material" and "precise five-axis grinding process". This brings: 1) Longer service life and better wear resistance; 2) Higher processing accuracy and consistency of chamfers; 3) Stronger rigidity and reliability, reducing the risk of breakage; 4) Better chip removal and surface finish. It is a high-end tool designed for professional users who pursue efficiency, accuracy, and long-term cost-effectiveness.