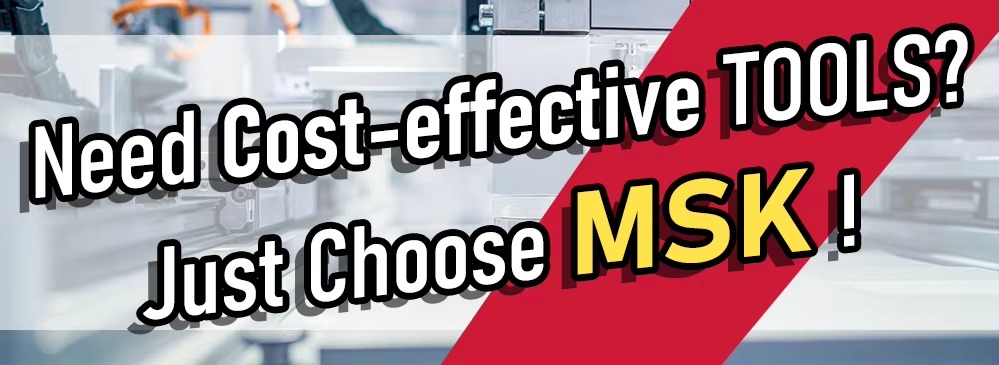

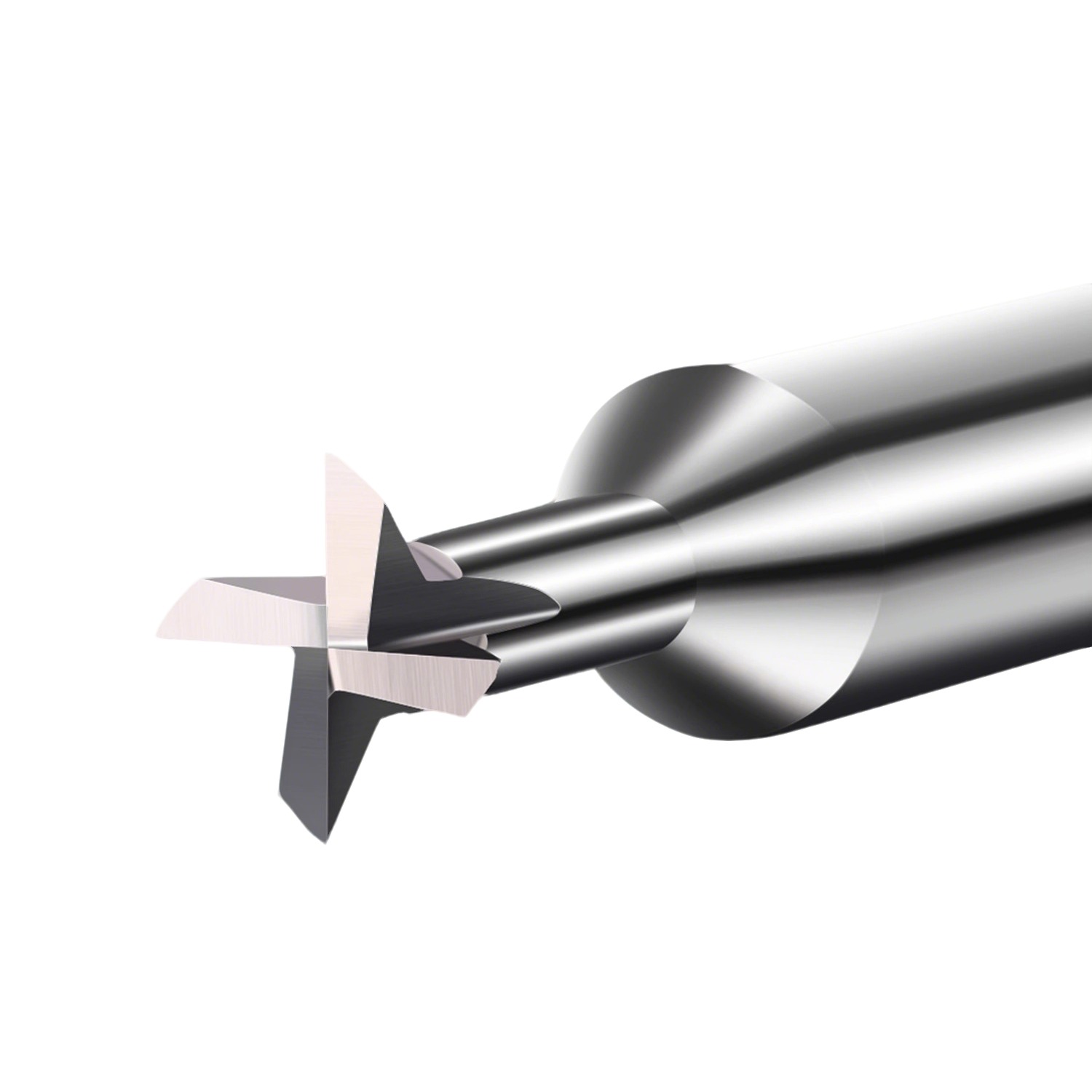

Precision Dovetail Cutter End Mill

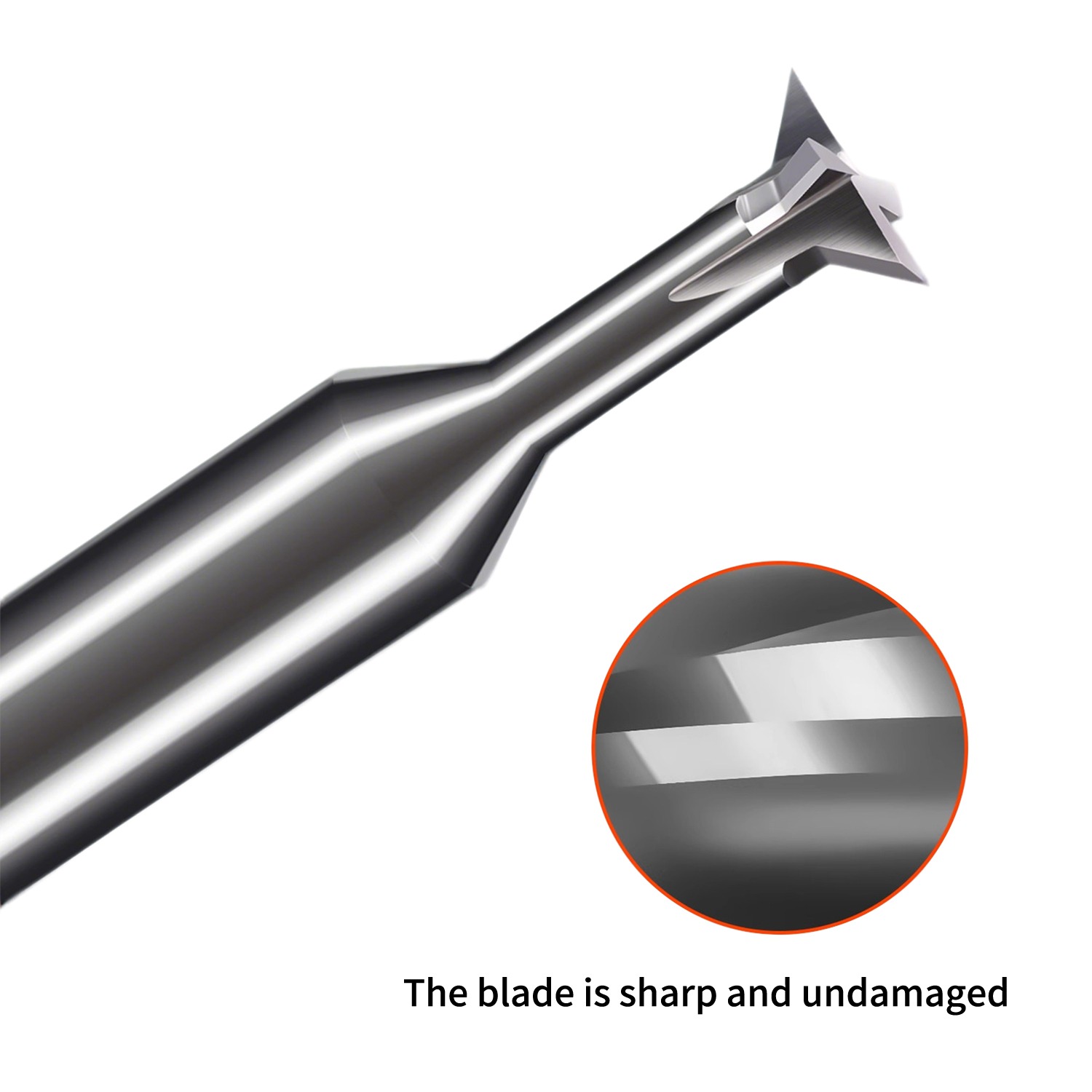

This precision 4-flute carbide end mill is engineered for longevity and high-performance machining of aluminum alloys. Its micro-grain tungsten carbide construction delivers superior wear resistance and rigidity, enabling fast chip removal and clean, precise cuts. The optimized large core diameter and chip space ensure exceptional vibration resistance and productivity in demanding applications.

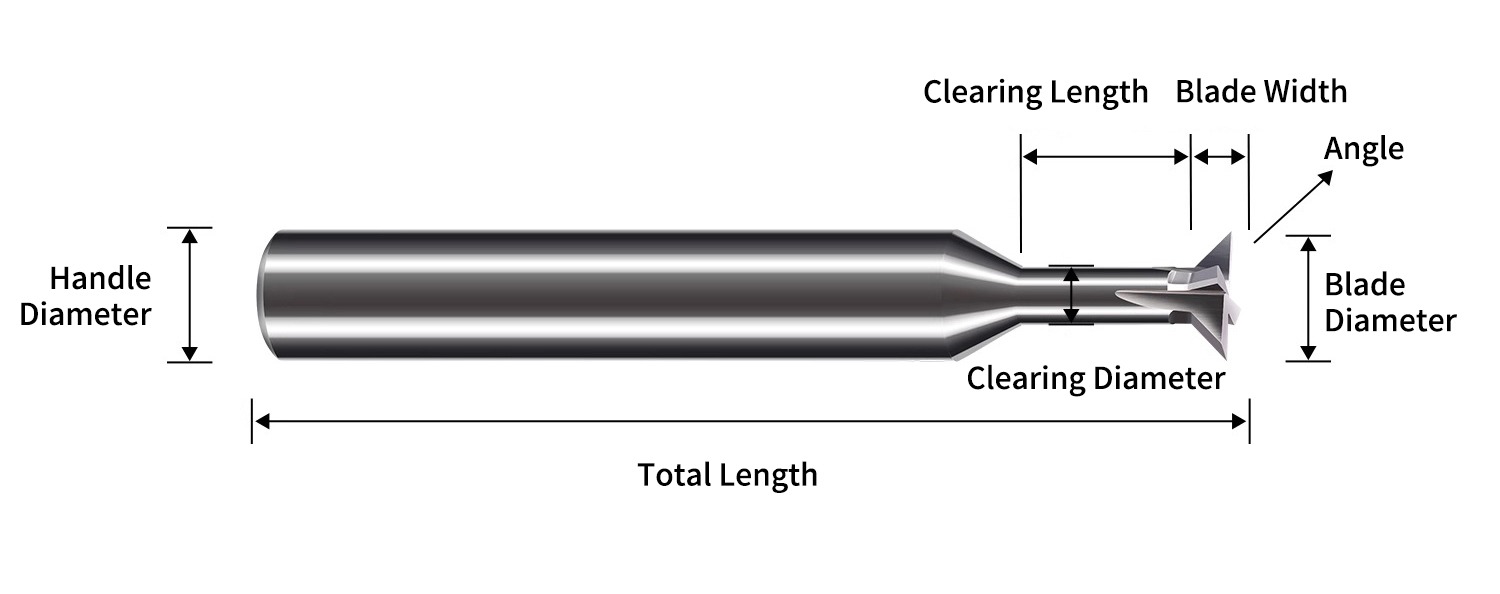

Important Attributes

| coating | Uncoated | HRC | / |

| material | Carbide | customized support | OEM |

| Applicable machine | Horizontal Milling Machine, Vertical Milling Machine | Cutting Direction | Conventional Milling |

| Cutting Edge Length | / | place of origin | Tianjin, China |

| model number | MSKDT | brand name | MSK |

| Cutting hardness | / | Effective Cutting Length | / |

| Flute | 4 flutes | Helix Angle | / |

| warranty | 3 MONTHS | Product Name | 4 Flute Solid Carbide Dovetail Cutter |

| Application | CNC Milling Machining | Flute | 4 |

| Usage | CNC Machine Center | Keywords | Tungsten Steel Dovetail Milling Cutter |

| Packing | 1ps/ Plastic Box | Processing Type | Metal Cutting Tools |

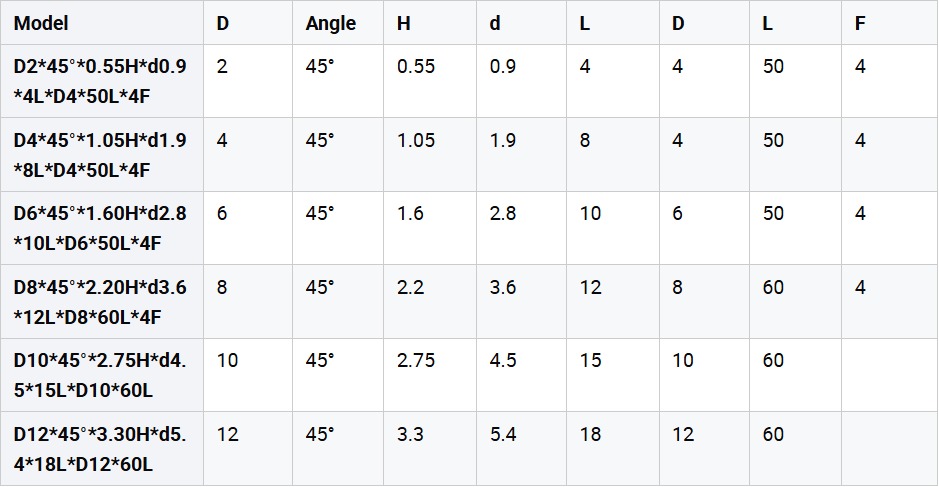

| Advantages | Sharp Cutting Edge | MOQ | 10 Pieces |

| Color | Sliver | ||

Product Features

Advantages

1.Outstanding durability and efficiency, hassle-free operation

Using a micro-particle tungsten steel substrate, it features extremely high wear resistance and hardness. It is specially designed for high-strength and high-load cutting scenarios, significantly extending the tool life, reducing the frequency of tool changes and long-term costs.

2. Rigorous strengthening, stable processing

The large-diameter design not only ensures sufficient chip storage space but also significantly enhances the rigidity and anti-vibration performance of the cutting tool, ensuring a stable cutting edge and precise angles. It is suitable for high-precision processing requirements.

3. Smooth operation, efficiency improvement

The wide chip-removal groove structure ensures that chips are discharged smoothly and quickly, avoiding clogging and overheating. It also takes into account the high heat resistance characteristic, enabling continuous and efficient production and enhancing the overall processing efficiency.

4. For optimization, professional and reliable

Special optimization has been carried out based on the material characteristics of aluminum alloys, etc. The four-edge design takes into account both cutting speed and surface finish, making it a reliable choice for processing structures such as precision T-shaped grooves and dovetail grooves.

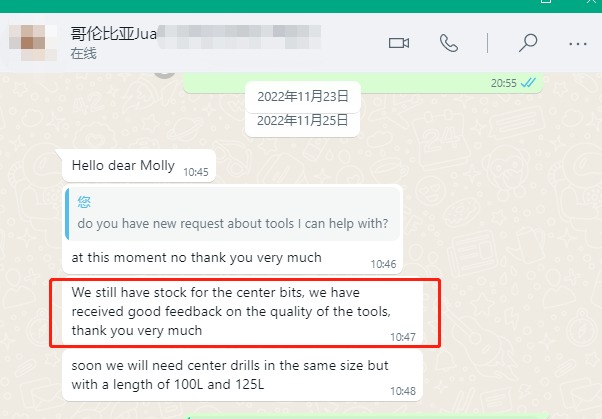

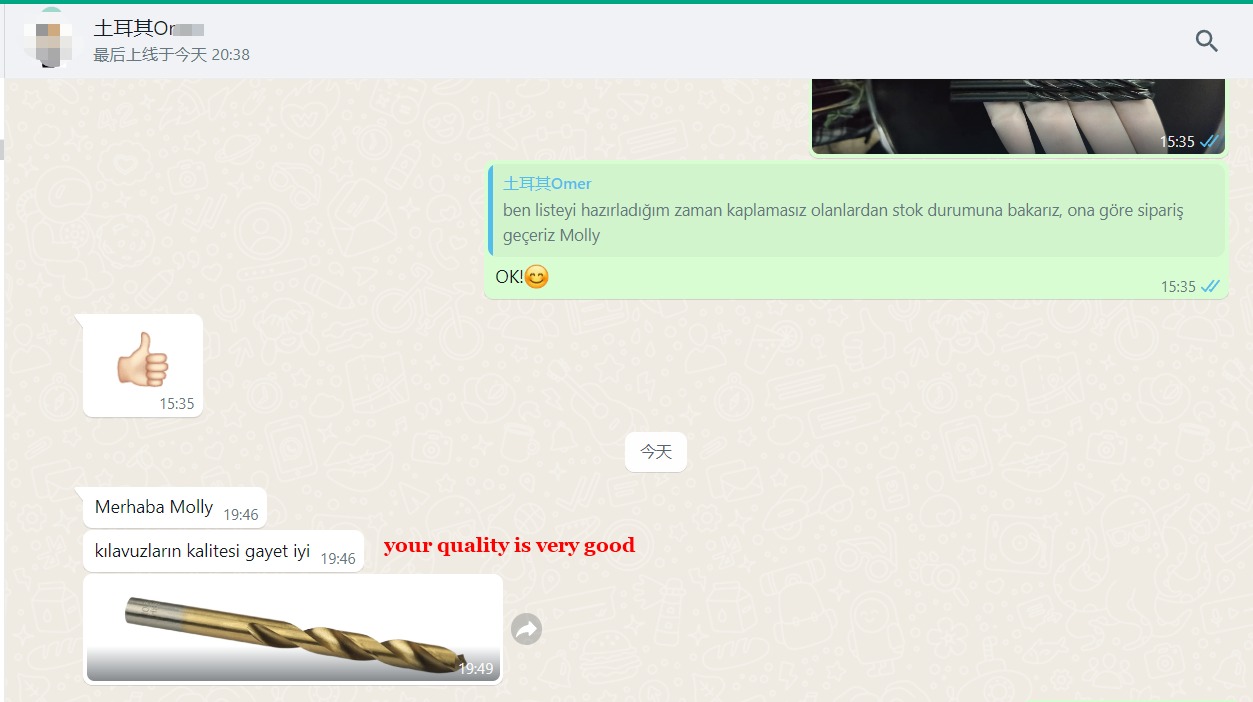

Why Choose Us

Factory Profile

FAQS

1. Q: What is the main application material of this milling cutter? Why is it suitable for processing aluminum alloys?

A: This four-edge hard alloy vertical milling cutter is specially designed forsuch as aluminum alloys. Its multi-edge groove design combined with excellent heat resistance enables rapid chip removal and avoids the formation of chip lumps, thus achieving high smoothness and smooth surfaces with no burrs in the processing of aluminum alloys.

2. Q: How are the "high rigidity" and "anti-vibration" features of the cutting tools designed?

A: We adopt a large-diameter design, which not only ensures sufficient chip retention space but also significantly enhances the overall rigidity of the cutting tool. Combined with strengthened cutting edge rigidity and precise cutting angles, the cutting tool can effectively suppress vibrations during high-speed and large-feed processing, ensuring high precision and long service life.

3. Q: What are the advantages of the "micro-particle tungsten steel hard alloy" base material used in this tool?

A: The micro-particle tungsten steel hard alloy base material has higher hardness and denseness, which gives the tool excellent wear resistance and strength. This makes it particularly suitable for processing high-hardness materials and working conditions with high cutting loads, allowing it to maintain sharpness for a long time and reducing the frequency of tool changes.

4. Q: How does the "large chip deflection groove" design of the cutting tool contribute to the processing efficiency?

A: The large chip deflection groove design ensures that the chips can be smoothly and quickly discharged during the cutting process, avoiding the problem of overheating, wear, or damage to the processing surface caused by chip blockage. This not only protects the cutting tool but also enables continuous and efficient production, especially suitable for deep slots or high-efficiency milling.

5. Q: As a factory-direct sold cutting tool, what guarantees does it have in terms of cost-effectiveness and reliability?

A: As a professional manufacturer, we complete the entire process from material selection, precision processing to quality control independently. The direct sales model ensures that you can obtain a reliable product with superior quality at a more favorable price. Each cutting tool undergoes strict inspection to provide long-lasting and stable processing performance, thereby reducing your overall usage costs.