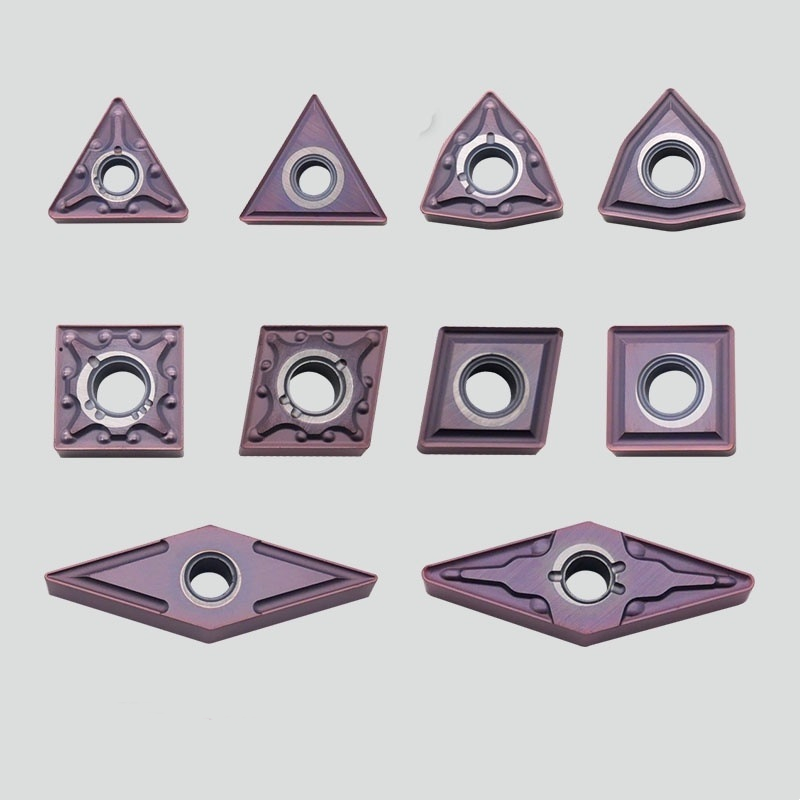

Designed explicitly for demanding CNC turning applications, these carbide turning inserts set a new benchmark in wear resistance, chip control, and productivity for workshops tackling challenging stainless alloys.

Stainless steel machining is notoriously difficult. Its tendency to work-harden, generate significant heat, produce tough, stringy chips, and cause severe tool wear has long plagued manufacturers, leading to frequent insert changes, compromised surface finishes, and reduced overall productivity. MSK's new inserts directly address these pain points with a sophisticated trifecta of design and material science.

Engineered for Peak Performance in Stainless Steel:

High-Efficiency Machining: At the core of these inserts is an advanced micro-grain carbide substrate formulated for exceptional hot hardness and resistance to deformation under the extreme pressures and temperatures encountered when cutting stainless steel. Combined with an ultra-smooth, optimized rake face geometry and a positive rake angle, the inserts significantly reduce cutting forces. This allows CNC turning centers to operate at higher cutting speeds and feed rates than previously possible with conventional inserts, dramatically boosting metal removal rates and slashing cycle times.

Wear-Resistant & Practical: Longevity is paramount. MSK utilizes a state-of-the-art multi-layered Physical Vapor Deposition (PVD) coating, such as a specialized TiAlN (Aluminum Titanium Nitride) variant. This coating provides an exceptional barrier against abrasive wear, crater wear, and the diffusion wear common when machining sticky stainless alloys. The result is dramatically extended tool life, reducing the frequency of insert indexing and tool changes. This translates directly to lower tooling costs per part, reduced machine downtime, and increased shop floor predictability. The robust substrate also enhances resistance against chipping and micro-fractures, ensuring consistent performance even under interrupted cuts common in stainless applications.

Smooth Chip Breaking: Uncontrolled chip formation is a major safety hazard and can damage both the workpiece and the tool. MSK engineers have meticulously designed a highly effective chipbreaker geometry integrated into the insert's top surface. This geometry precisely guides the chip, inducing controlled curl and breakage into manageable, safe "C" or "6" or "9" shaped fragments across a wide range of cutting parameters (feeds, depths of cut). Consistent, smooth chip evacuation prevents chip entanglement around the tool or workpiece, protects the cutting edge from re-cutting chips, improves surface finish, and enhances operator safety. This reliable chip control is essential for unattended or lights-out CNC turning operations.

Optimized for CNC Turning Productivity: These inserts are designed to maximize the capabilities of modern CNC turning centers. Their consistent performance allows programmers to confidently push machines to their optimal parameters, knowing the inserts can handle the demands of stainless steel. The combination of high-speed capability, extended tool life, and reliable chip breaking minimizes non-cutting time and ensures smoother, more efficient production runs.

Target Applications: These specialized inserts are ideal for machining a wide range of austenitic (e.g., 304, 316), duplex, and super duplex stainless steels across critical industries including:

Oil & Gas (Valves, Fittings)

Aerospace (Hydraulic Components)

Medical Device Manufacturing (Implants, Instruments)

Chemical Processing Equipment

Food & Beverage Machinery

General Precision Engineering

About MSK

MSK (Tianjin) International Trading CO.,Ltd was established in 2015, and the company has continued to grow and develop during this period. The company passed the Rheinland ISO 9001 certification in 2016. It has international advanced manufacturing equipment such as the German SACCKE high-end five-axis grinding center, the German ZOLLER six-axis tool testing center, and the Taiwan PALMARY machine tool. It is committed to producing high-end, professional and efficient CNC tools.

Post time: Jun-23-2025