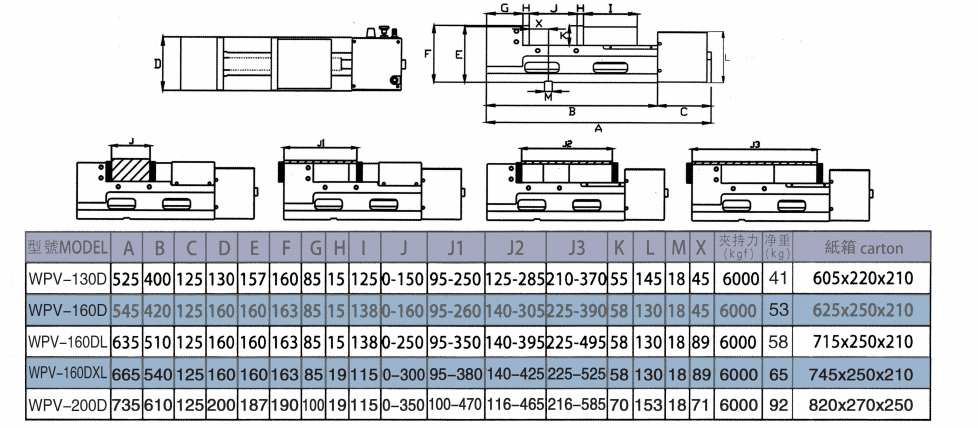

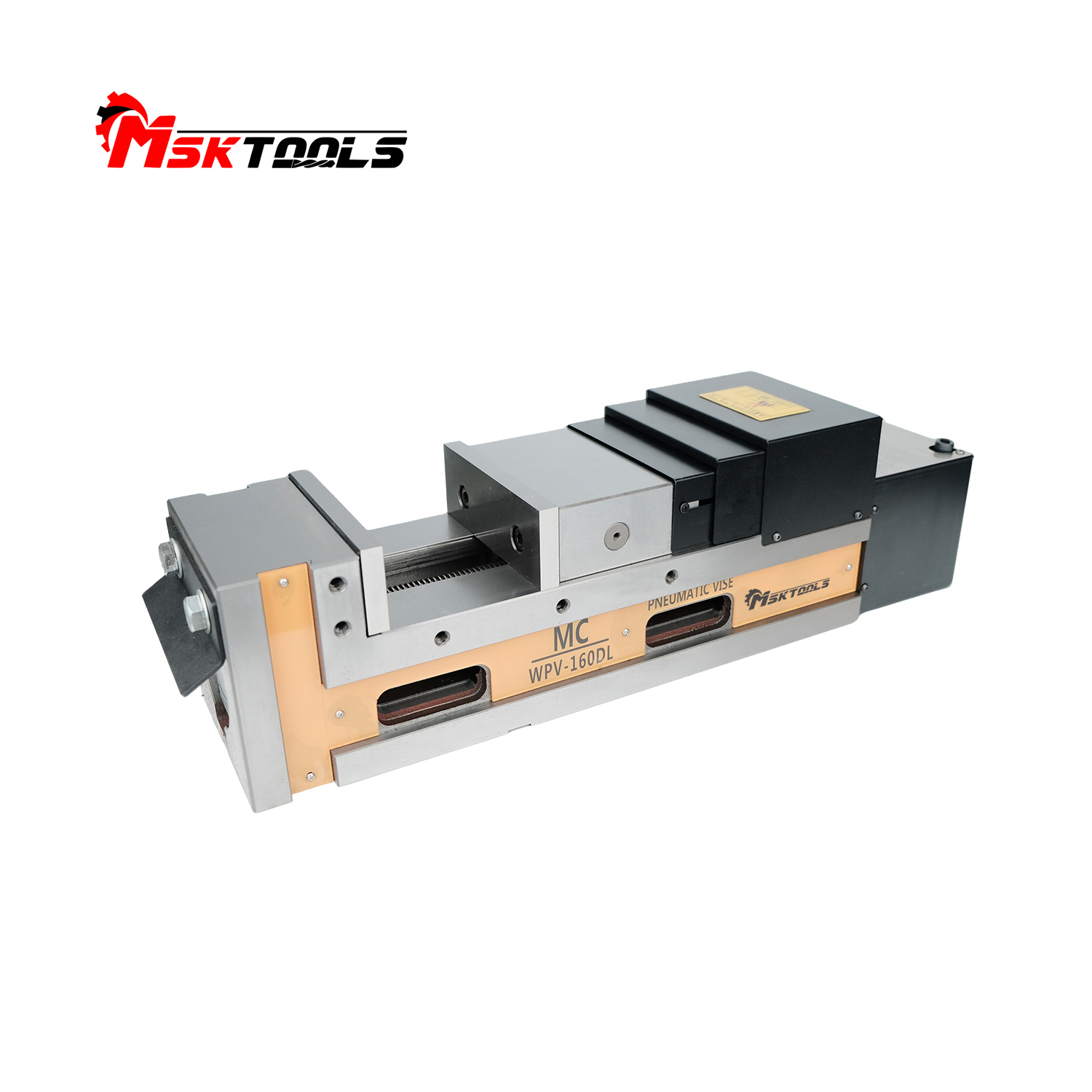

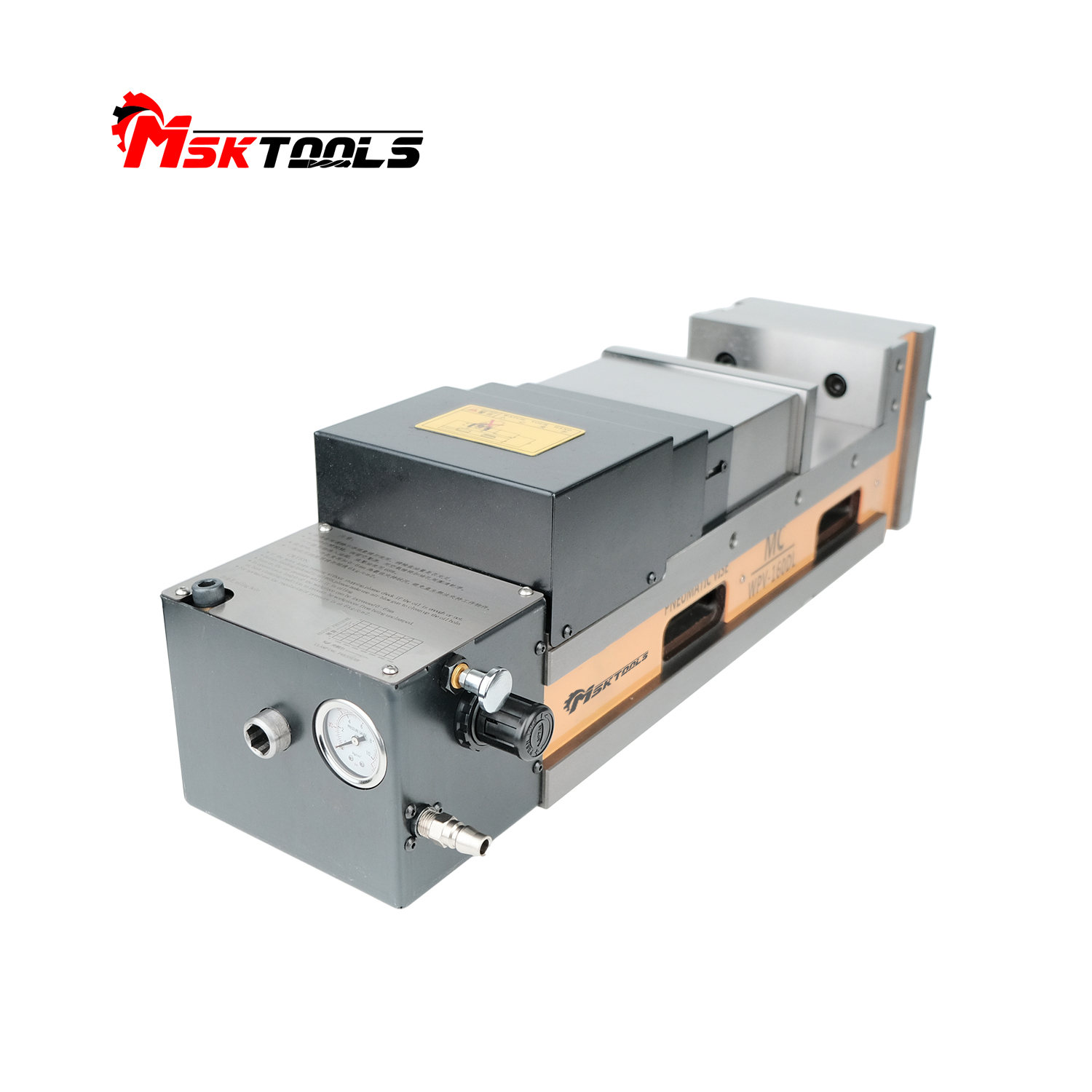

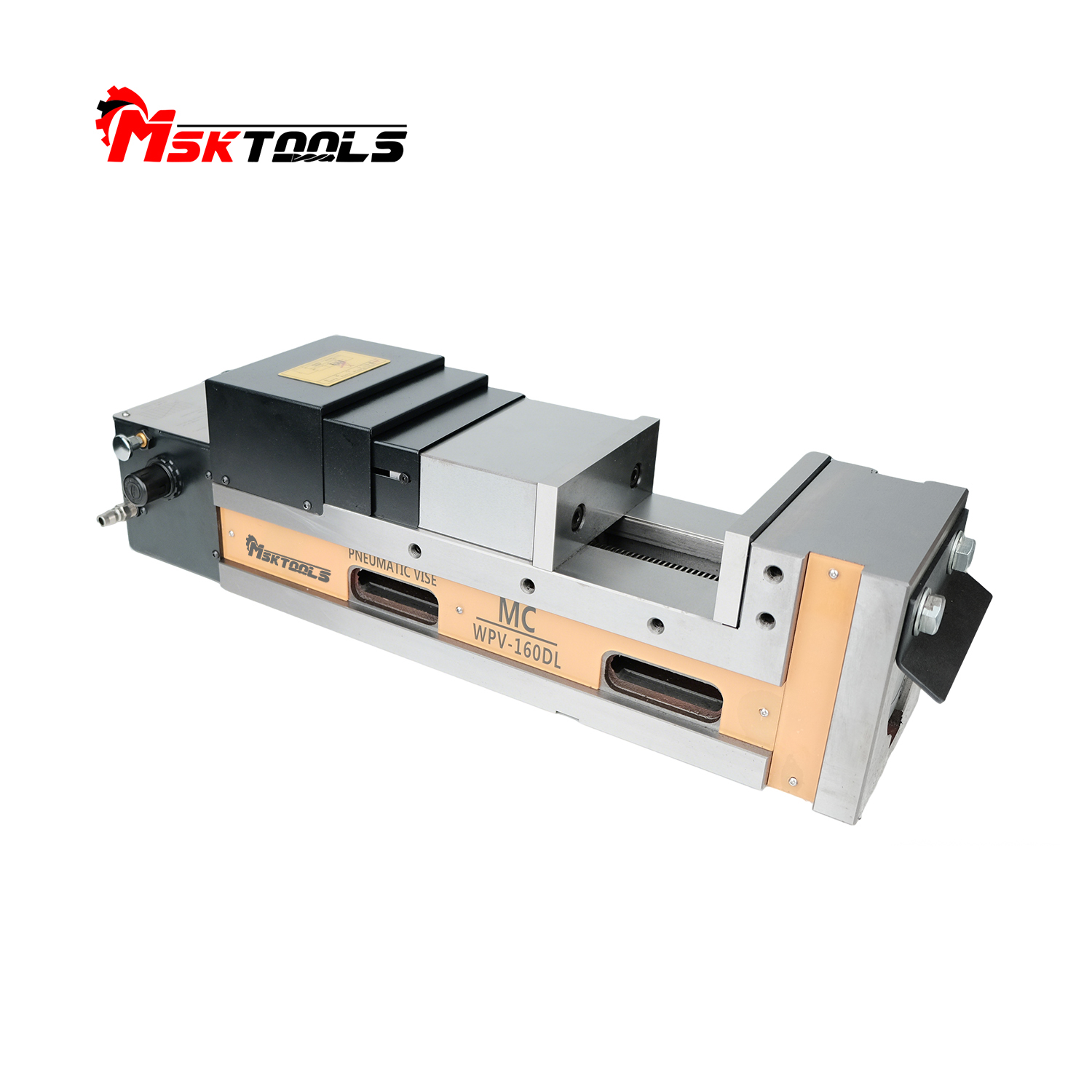

MC Precision Super Hi-Pressure Rapid Vise

Super hi-pressure rapld vise is designed for both light processing of copper and aluminum workpieces and heavy cutting of cast iron, maintaining stable clamping pressure even under varying air supply conditions. It features a fast switching speed of just 1.5 seconds, a safe holding distance of 6mm for operator protection, and can be integrated into automated unmanned production systems.

Important Attributes

Product Features

1.It can be modified for use as an electrically controlled pneumatic hydraulic vise or foot switch

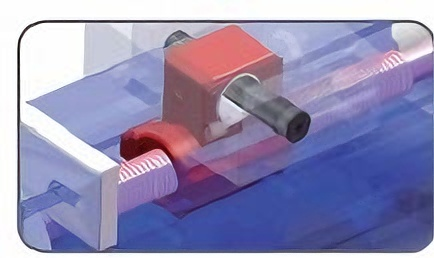

2.Hidden antifloating transmission mechanism

The downward force during clamping also acts,Therefore,the upward movement of the workpiece and movable body is extremely small. The body and fixed jaw are constructed as a whole,Therefore,it can prevent the tilting of the clamp body.

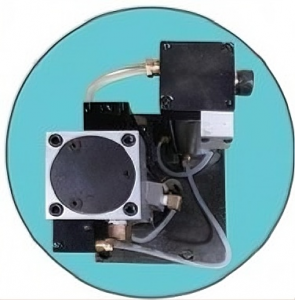

3.Adopting self-developed reciprocating technology Type air compressor motor,Continuously pushing the oil circuit with air pressure Method to achieve automation.

Advantages

1. Superior Rigid Structure and Clamping Stability

Integrated Rigid Design: The clamp body and fixed jaws are integrally molded, effectively preventing tilting during machining and ensuring extremely high overall rigidity.

Downward Clamping Principle: The clamping force primarily acts downwards, greatly reducing upward displacement of the workpiece and moving clamp body, achieving more stable and precise clamping.

2. Intelligent and Reliable Pressure Control System

Adaptive Pressure Stabilization Technology: Utilizing independently developed reciprocating pneumatic-hydraulic technology, power transmission is achieved by continuously driving the hydraulic circuit with air pressure. The regulator has automatic pressure compensation and stabilization functions, maintaining the preset clamping pressure even under fluctuating air source pressure or varying demands from light machining to heavy cutting, eliminating the risk of pressure loss.

Wide Pressure Adjustment Range: Users can freely set the required clamping force via the pressure regulator to adapt to various working conditions, from light machining of copper and aluminum to heavy cutting of cast iron blanks.

3. Highly Efficient, Safe, and Flexible Operation

Rapid Opening and Closing: Under manual switch control, clamping and releasing takes only about 1.5 seconds, significantly reducing clamping time and improving production efficiency.

Safety Protection: Designed with a 6mm safety clamping distance, providing physical protection during operation and effectively preventing accidental injury.

Automation Compatibility: Not only can it be operated manually, but it can also be seamlessly integrated into automated unmanned production systems (controlled via solenoid valves or machine tool controllers), providing key support for achieving intelligent manufacturing.

4. Lasting Precision and Durability

High-Strength Material: The clamp body is made of high-ductility spheroidal graphite cast iron (FCD600), possessing high tensile strength.

Reinforced Key Components: The guide rails on both sides of the clamp body are heat-treated and hardened (HRC42°), ensuring high precision, high wear resistance, and a long service life.

Why Choose Us

Factory Profile

FAQS

1. Q: Will the clamping force of this vise weaken due to unstable air supply?

A: No. This vise employs automatic pressure compensation and stabilization technology. Even when machining copper and aluminum (light cutting) or cast iron blanks (heavy cutting), it automatically maintains a stable clamping force under the set pressure, ensuring that clamping failure will not occur due to air supply pressure fluctuations.

2. Q: Will the clamping action of the vise cause the workpiece to float or misalign?

A: Virtually not. Its clamping force mainly acts downwards, effectively suppressing upward displacement of the workpiece and the moving jaws. Simultaneously, the vise body and fixed jaws are designed as a single unit, preventing the vise body from tilting during clamping and ensuring positioning accuracy.

3. Q: How fast is the opening and closing speed of this vise? Is it safe to operate?

A: The opening and closing speed is extremely fast, requiring only about 1.5 seconds. It has a 6mm safe clamping distance, effectively preventing accidental injury during operation. It also supports operation via manual switch, electric control valve, or machine tool controller, adapting to various working modes.

4. Q: Can it be used in automated production lines?

A: Absolutely. This product is designed to integrate with automated unmanned production systems. Automatic tightening and loosening can be achieved via external electric valves or machine tool controller signals. It is suitable for CNC machining units or flexible manufacturing systems requiring fully automated clamping.

5. Q: Can the structure and materials of the vise guarantee long-term accuracy and durability?

A: Yes. The vise body is made of high-strength ductile iron (FCD600), with an integral design. The guide rails on both sides are heat-treated and hardened to HRC42°, possessing high tensile strength, high wear resistance, and high rigidity. It can maintain machining accuracy over a long period and is suitable for high-load cutting environments.