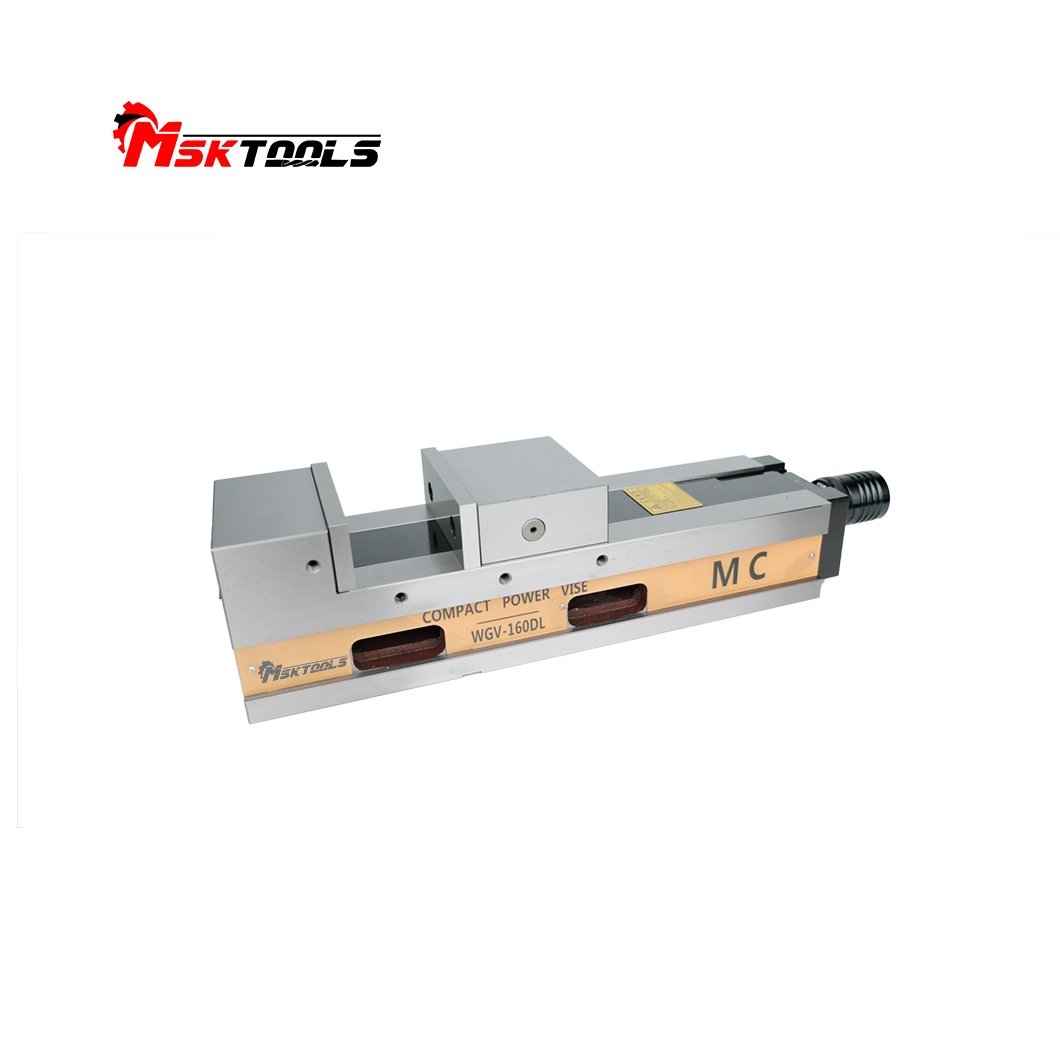

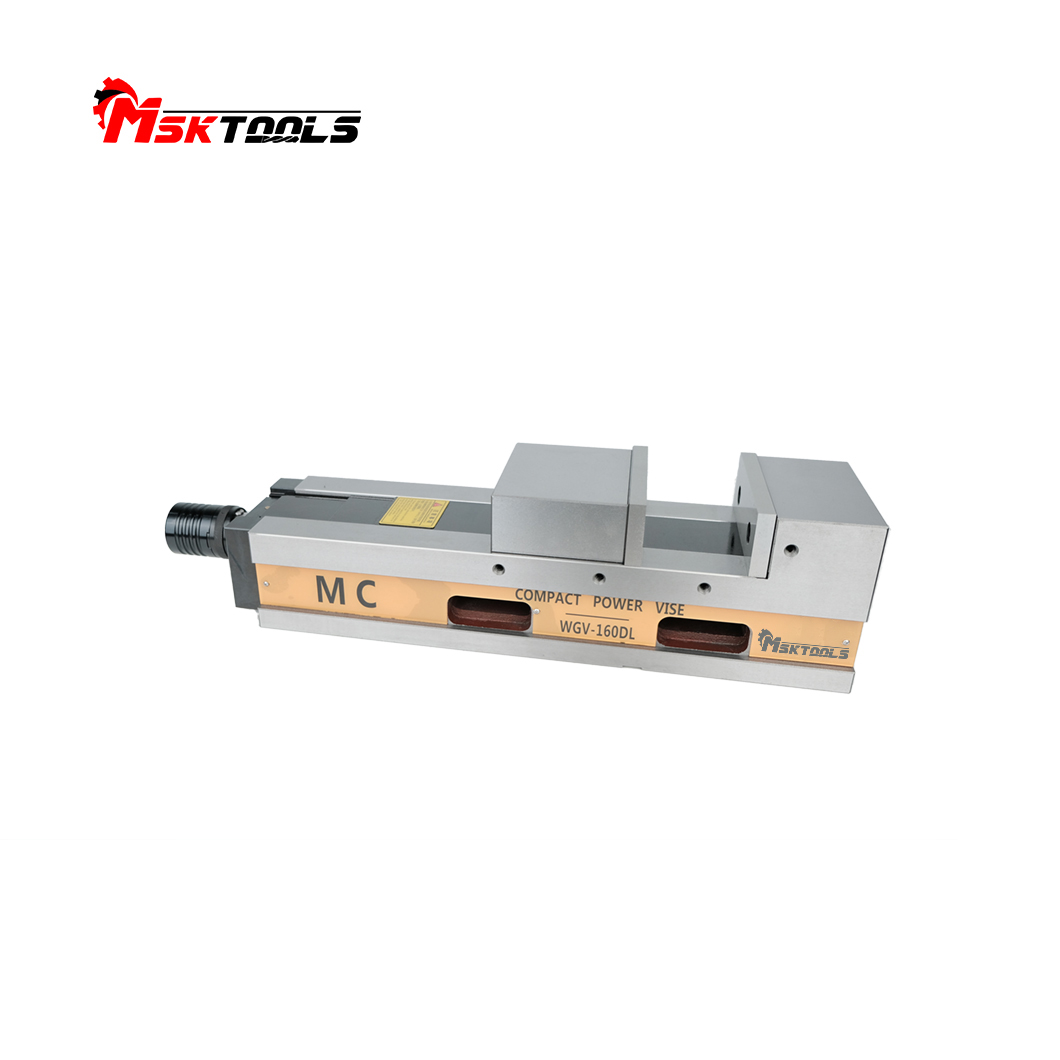

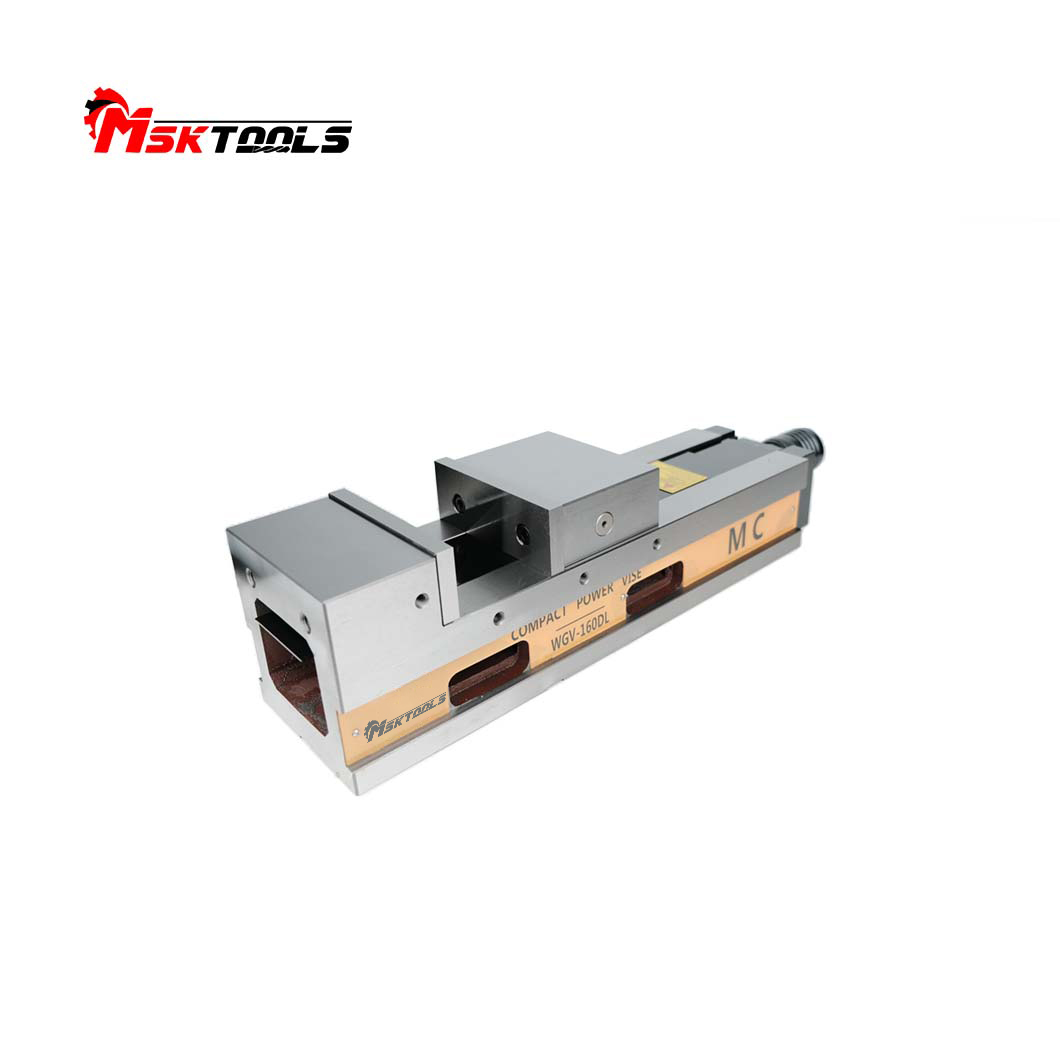

MC Precision Power Vise-Mechanically Pressurized

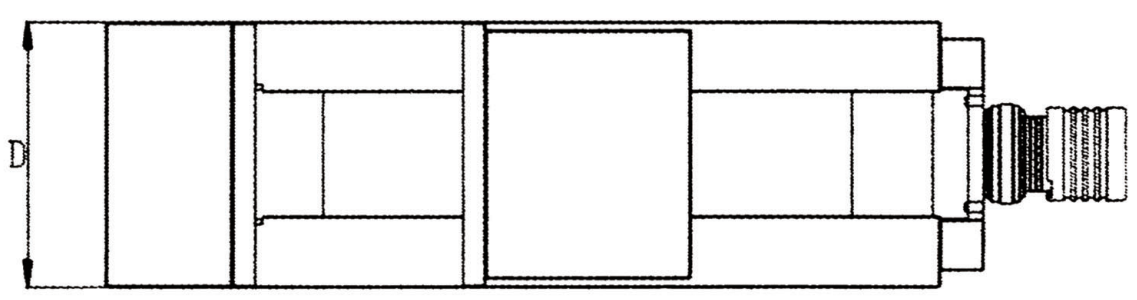

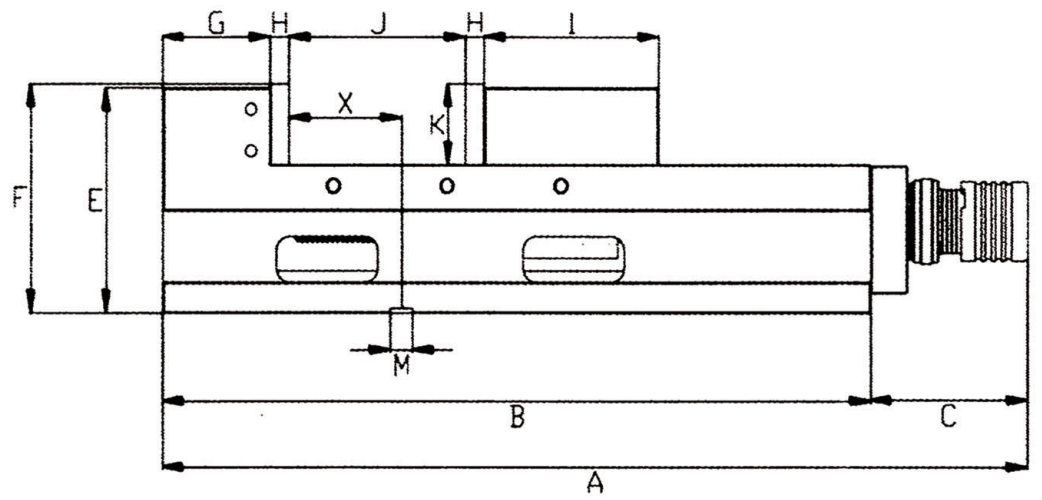

MC Precision Power Vise-Mechanically Pressurized is a high-end modular hydraulic vise specially designed for horizontal machining centers and high-performance precision milling/cutting processes. It integrates ultra-high precision, ultimate rigidity, super strong clamping force and long-lasting durability. Through full-process precision processing and innovative patented design, it provides a reliable workpiece clamping solution for harsh metal processing environments, especially suitable for manufacturing fields that require long-term, high-load and high-precision processing.

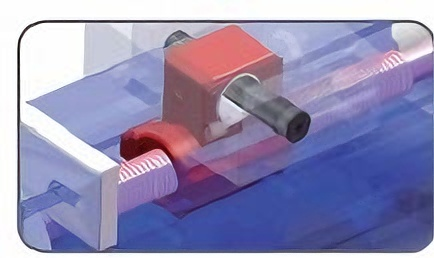

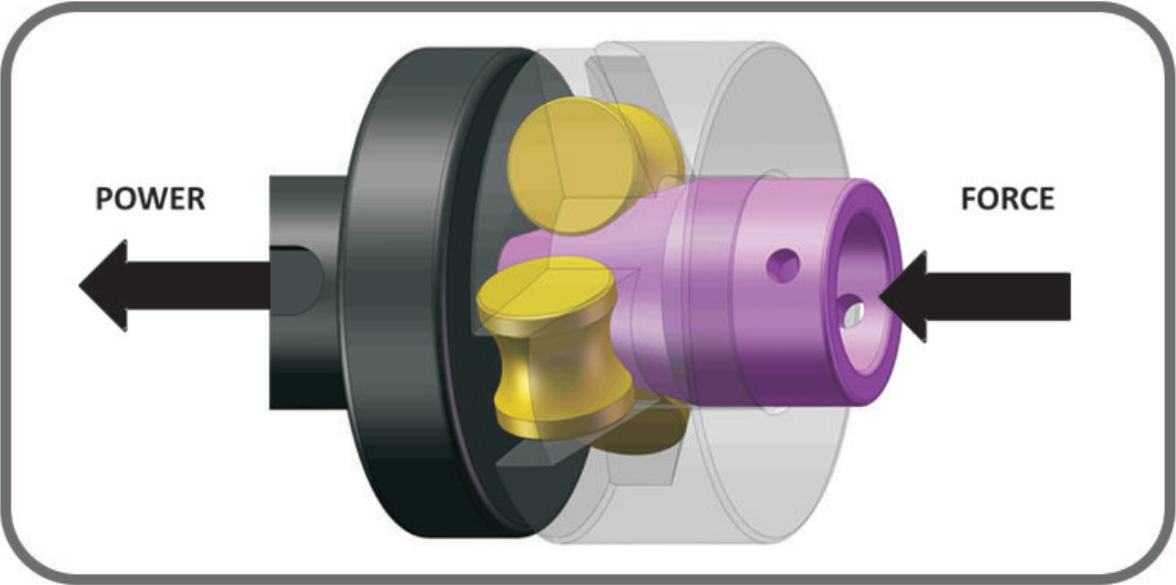

It is equipped with an internal anti-floating transmission mechanism

When clamping, the downward force also acts, so the upward floating of the workpiece and the movable body is extremely small. The main body and the fixed jaw are integrated into one structure, thus preventing the tilting of the clamp body.

The unique pressure-increasing device ensures your safety and no loss of pressure.

The MC mechanical force doubling and pressure boosting vise is a high-performance fixture specially designed for modern high-load processing environments. Its precise force doubling and pressure boosting mechanism can easily handle various processing requirements from light cutting to heavy cutting, ensuring convenient operation and stable and reliable clamping.

The clamp body is integrally cast from high-strength ductile iron FCD600, featuring outstanding tensile strength and deformation resistance. Combined with the hardening treatment of the sliding surface above HRC42, it ensures the product's ultimate wear resistance and precision durability under long-term heavy-load use. This vise is particularly suitable for vertical and horizontal integrated machining centers and FMS flexible manufacturing systems. Its integrated structure can effectively suppress the backward tilt of the vise and the upward floating of the workpiece during clamping, providing a firm and precise clamping solution for heavy cutting operations.

What customers say about us

FAQ

1. How strong is the clamping force of this vise and in which processing scenarios is it suitable?

This product adopts a unique patented mechanical force-doubling pressure-increasing design, with a maximum clamping force of up to 5000 kgf. It is suitable for all kinds of processing from light cutting to heavy cutting, especially for high-intensity and high-load heavy cutting operations in vertical and horizontal integrated cutting machines and FMS flexible manufacturing systems.

2. How can the durability and precision of the vise be guaranteed?

The clamp body is made of high-strength ductile iron FCD600 in one piece. Combined with the hardening treatment of the sliding surface and the clamp mouth at HRC42° or above, it ensures high tensile strength and anti-deformation ability, while achieving excellent wear resistance and long-term precision stability.

3. What are the error-proof and damage-proof features of the product in terms of structural design?

The vise is equipped with an internal anti-floating transmission mechanism, which generates a downward force during clamping, greatly inhibiting the upward floating of the workpiece. At the same time, the main body and the fixed jaw are integrated in structure, which can effectively prevent the clamp body from tilting or tilting backward. In addition, the patented anti-chip design can prevent iron filings from entering the interior, thus extending the service life.

4. Is the power boosting device safe and reliable? Will it lose pressure halfway?

This product is equipped with a unique double-force pressure-increasing device. Its mechanical structure has been precisely designed and verified, capable of maintaining a stable high clamping force while rapidly increasing pressure, achieving a reliable performance that is safe and pressure-free, ensuring a firm and safe processing procedure.

5. Is this vise suitable for automated or high-precision production lines?

Yes. Each track of the vise has undergone precise processing and polishing. Combined with the overall rigid design and anti-floating and anti-tilting structure, it is highly suitable for integration into automated systems such as horizontal machining centers. Its high repeat positioning accuracy and anti-interference ability can meet the strict requirements for clamping stability in FMS systems and precision machining.

The MC Mechanical Force-Boosting Vise is a professional clamping tool designed for heavy-duty cutting and high-precision machining environments. It is widely used in vertical and horizontal integrated cutting machines and FMS flexible manufacturing systems. Its core design integrates a high-rigidity structure, patented pressure-boosting technology, and long-lasting wear-resistant protection, aiming to provide a stable and reliable clamping solution for high-intensity machining.

Design and Composition

The vise body is integrally cast from high-ductility spheroidal graphite cast iron FCD600, with a tensile strength of up to 60 kgf/mm², ensuring structural strength and resistance to deformation.

Key sliding surfaces and jaws undergo hardening heat treatment, achieving a hardness of HRC42 or higher, effectively improving wear resistance and service life.

Equipped with a patented mechanical force-boosting device and built-in chip protection design, it balances powerful clamping with internal mechanism protection.

The body and fixed jaws adopt an integral construction, combined with a concealed anti-lift transmission mechanism, suppressing tilting and lifting during clamping from the design stage.

Features

High-efficiency pressure-boosting clamping: A unique mechanical force-multiplying design achieves rapid clamping and a strong clamping force of up to 5000 kgf, ensuring no workpiece displacement during light or heavy cutting.

Anti-floating and anti-tilting protection: A downward additional force is generated during clamping, significantly reducing the upward movement of the workpiece and moving parts; the integrated structure effectively resists backward tilting of the vise, ensuring machining perpendicularity.

Long-lasting chip protection and wear resistance: An optimized chip-proof structure prevents chips from entering the internal mechanism, and combined with hardened sliding rails, significantly extends the vise's service life in harsh environments.

Safe and pressure-free: The pressure-boosting mechanism has self-locking and pressure-holding characteristics, maintaining stable clamping force during long-term machining and avoiding safety hazards caused by pressure loss.

Application Scenarios

This product is specifically designed for vertical and horizontal machining centers and FMS system integration, and is especially suitable for the following high-requirement machining scenarios:

Heavy cutting machining, such as milling, drilling, and tapping of steel, cast iron, and high-strength alloys.

Mass production of precision components demands high repeatability and clamping stability.

Automated production lines require robotic arms to enable rapid workpiece clamping and continuous machining.

Precision Machining Support

Each slide rail undergoes precision machining and polishing to ensure smooth movement and accurate positioning.

A high-rigidity, integrated body and hardened sliding surfaces together ensure the vise maintains its geometric accuracy over long-term use.

Suitable for high-precision mold processing, aerospace component manufacturing, and other fields highly sensitive to clamping deformation.

Challenges and Considerations

Under extreme heavy cutting conditions, it is essential to ensure consistently uniform clamping force to prevent workpiece deformation caused by localized stress.

When applied to automated systems, appropriate cleaning and maintenance procedures are necessary to leverage the long-term protective effect of the chip-resistant design.

While the design accommodates both light and heavy cutting, clamping strategies and parameter settings still need to be evaluated based on actual working conditions in ultra-high frequency vibration environments.

The MC Mechanical Force-Boosting Vise, with its integrated high-rigidity structure, patented force-boosting mechanism, anti-floating and anti-tilting mechanism, and long-term wear-resistant protection, has become a reliable heavy-cutting partner in modern high-efficiency machining. It not only improves machining accuracy and stability, but also reduces maintenance needs through user-friendly design, making it an ideal fixture choice for manufacturing companies that pursue production efficiency and quality.