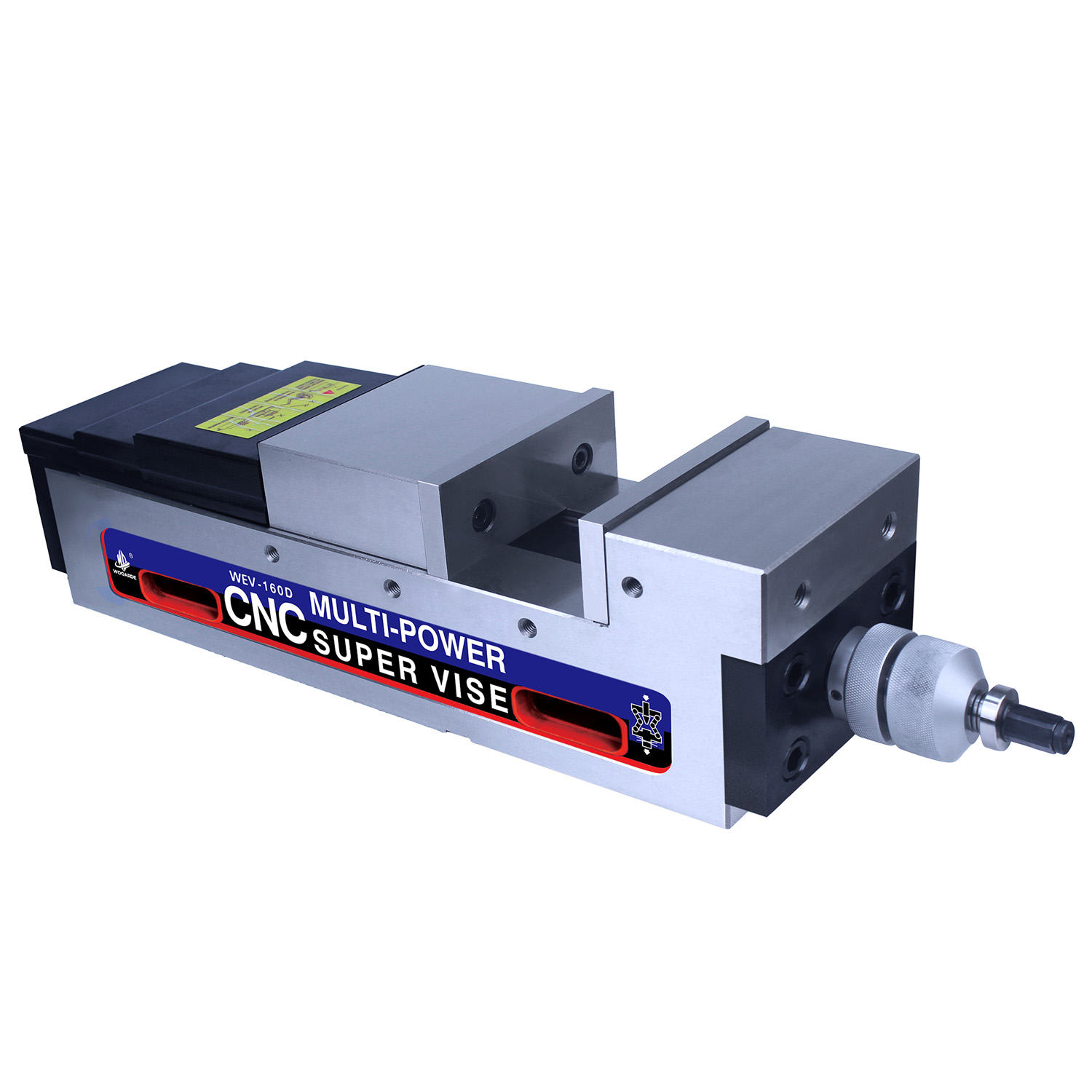

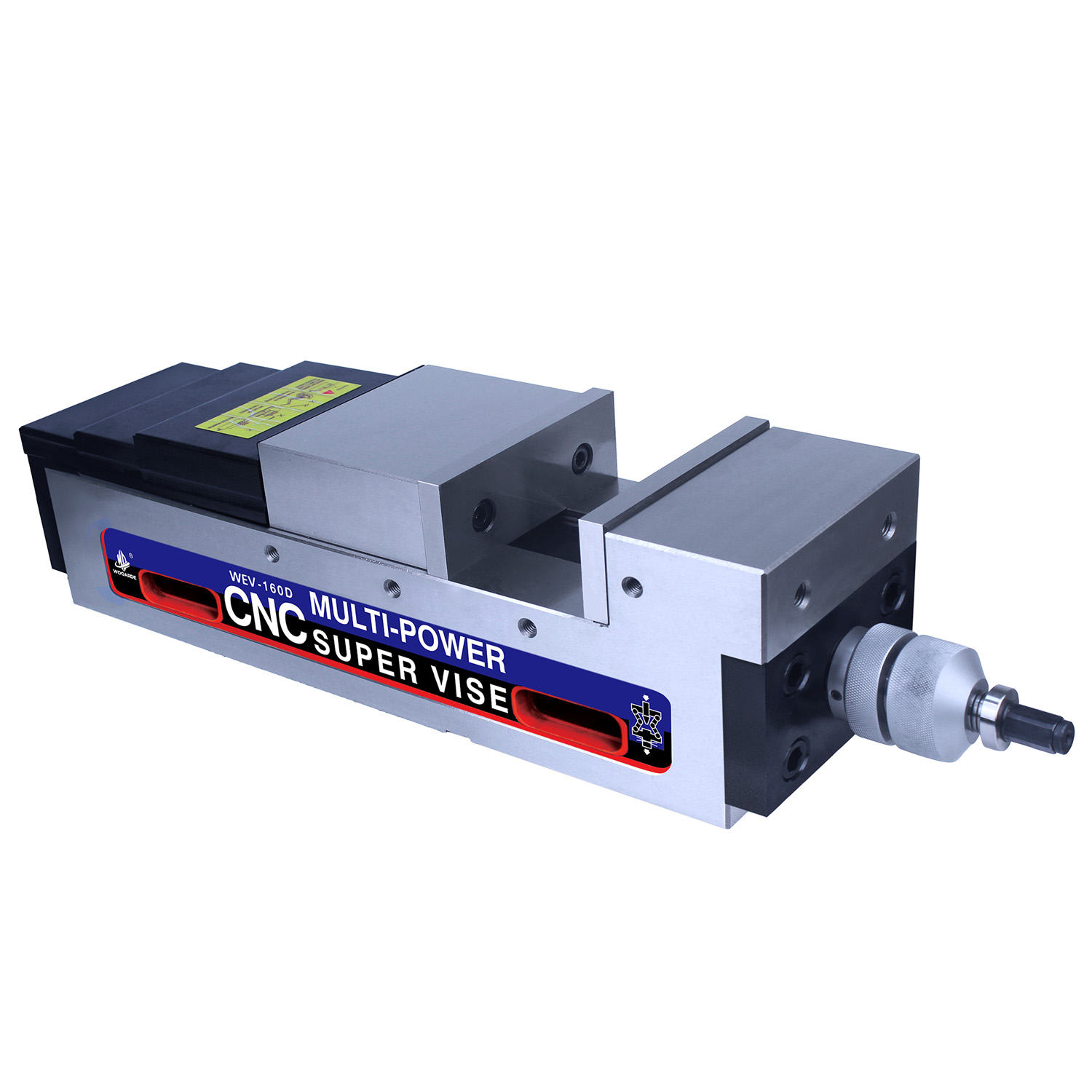

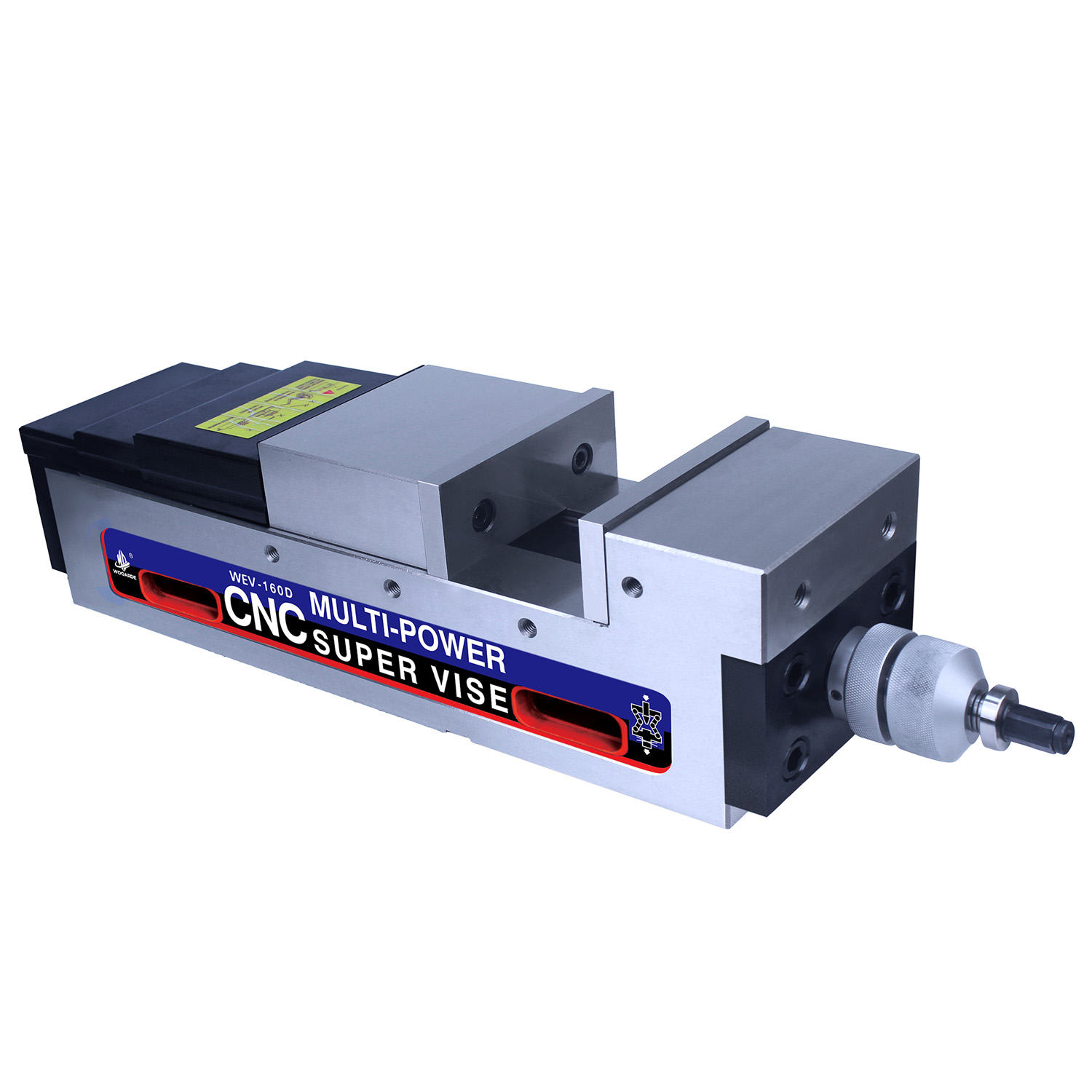

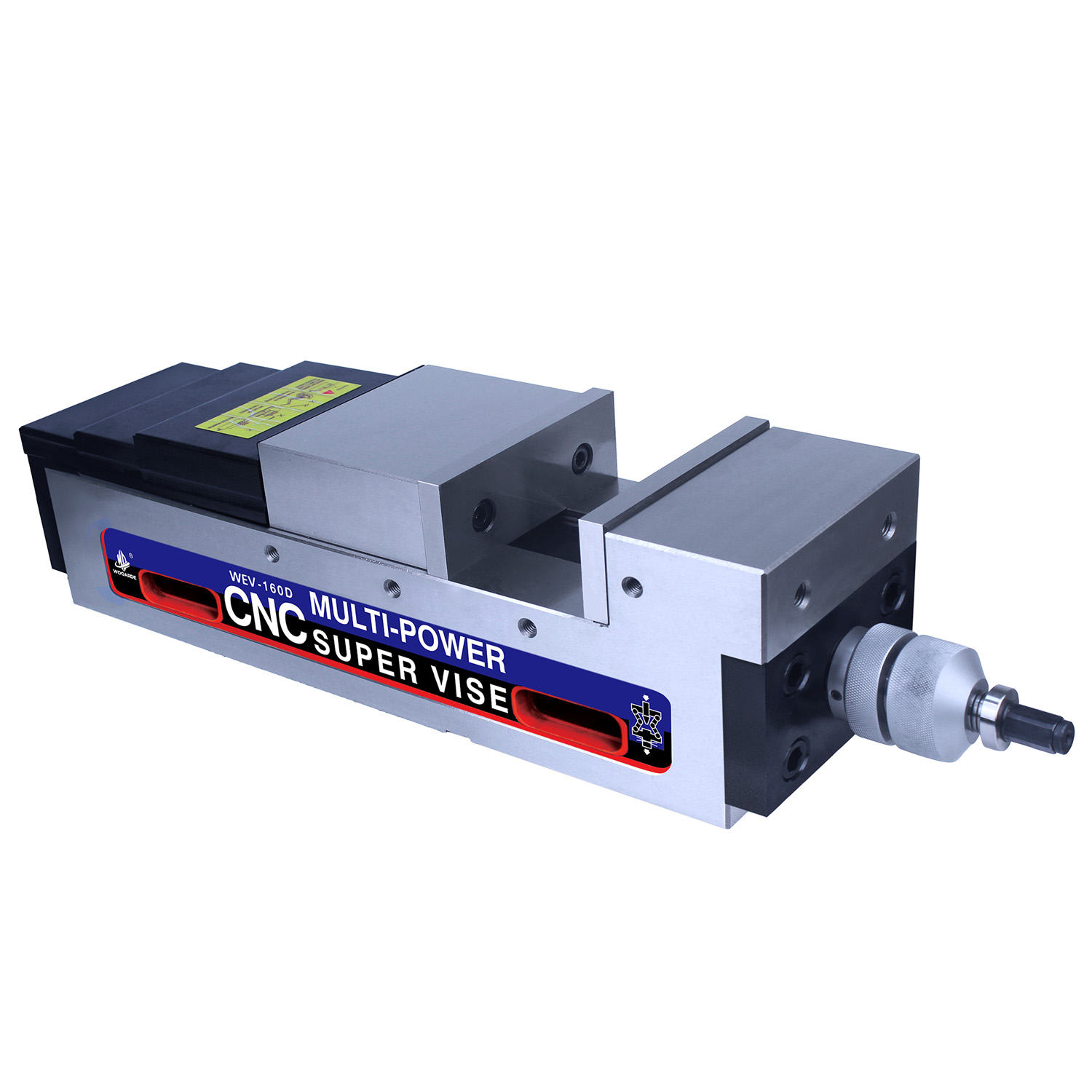

MC Multi-Power Super Vise

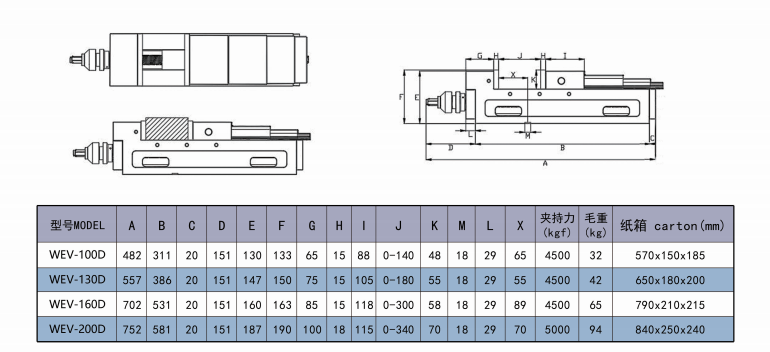

The MC Multi-Power Super Vise is specially designed for vertical/ horizontal comprehensive machining centers and FMS systems. Through precise hydraulic amplification and patented pressurization mechanisms, it can achieve a powerful clamping force of up to 5000 kilograms, perfectly capable of handling heavy cutting operations. It is manufactured using high-strength FCD600 ductile iron for one-piece molding, with key sliding surfaces and jaws having a hardness of HRC42 or above, ensuring extremely high rigidity, resistance to deformation, and long-lasting wear resistance. The product is equipped with a pressure regulating ring that can preset the clamping force, ensuring consistent clamping force each time and featuring effective chip-removal design. The operation is simple, stable, and reliable.

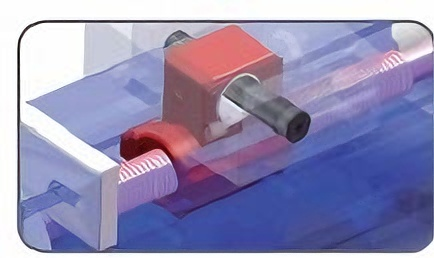

Hidden anti floating transmission mechanism

The downward force during clamping also actsTherefore,the upward movement of the workpiece and movable body is

extremely small.The body and fixed jaw are constructed as a whole,Therefore,it can prevent the tilting of the clamp body.

Adjusting stop ring:this simple and effective presetting device enables to preset each desired clamping force and it guaranteesto repeat each clamping operation at the same clamping force.

The MC precision hydraulic vise is a product specially designed for vertical and horizontal comprehensive processing centers and FMS systems, suitable for high-demand heavy cutting operations. Its core features include precise hydraulic amplification and patented pressure-boosting mechanism, making it easy to operate and boasting a powerful clamping force of up to 5000 kgf, capable of handling both light and heavy cutting tasks with ease.

The product is made of a single-piece high-strength spherical graphite cast iron (FCD600). The key sliding surfaces and jaws have a hardness of above HRC42°, ensuring excellent rigidity, wear resistance and accuracy retention. Additionally, it is equipped with a pressure regulating ring that can preset the clamping force, ensuring consistent clamping force in each operation. Combined with a chip prevention design, it effectively extends the service life.

What customers say about us

FAQ

1.Q: In which types of machine tools is this hydraulic vise suitable for use? What types of processing can it perform?

A: It is specifically designed for vertical, horizontal comprehensive machining centers and FMS (Flexible Manufacturing System). Its strong clamping force and rigidity make it particularly suitable for heavy cutting operations, and it can also perfectly meet the requirements of precision cutting.

2. Q: What are the core advantages of this product? How can its stability and lifespan be guaranteed in heavy cutting operations?

A: The core advantage lies in the combination of the precise oil pressure amplification design and the high rigidity structure. The clamp body is made of one-piece high-strength ductile iron (FCD600), with the sliding surface hardness reaching above HRC42°, ensuring wear resistance and deformation resistance. The patented pressurization mechanism can generate a maximum clamping force of up to 5000 kgf, combined with the built-in anti-floating transmission mechanism, it can effectively prevent the workpiece from floating and the clamp body from tilting, ensuring absolute stability during heavy cutting operations.

3. Q: How is the precise, rapid control and consistency of the clamping force achieved?

A: The product is equipped with a patented hydraulic rapid pressure application mechanism, which is easy to operate. The key is its unique adjustment stop ring (pressure regulating ring), which is a simple and effective preset device. It allows the operator to pre-set the required clamping force and ensures that each clamping operation will repeat the same precise force, thus guaranteeing processing consistency.

4. Q: How does the product address the maintenance challenges in the processing site during design?

A: This vise adopts a chip-removal design, which can effectively prevent iron chips from entering the internal transmission mechanism of the vise and also has an internal structure that facilitates the discharge of iron chips. This not only reduces the occurrence of faults caused by chip entrapment, but also significantly extends the service life of the vise, and reduces the difficulty and frequency of daily maintenance.

5. Q: How are the clamping accuracy and repeat positioning accuracy of the product guaranteed?

A: Firstly, it is manufactured through high-precision machining and grinding processes. Secondly, the body and the fixed jaw are integrated, eliminating the clearance in the connection from the very beginning and preventing the backward tilt and shaking during clamping. Finally, the adjustable moving block design (as mentioned) or the high-precision manufacturing benchmark allows users to make fine adjustments to maintain the best clamping accuracy of the vise over a long period.

The MC series precision hydraulic vise is a high-performance clamping solution specifically designed for modern vertical and horizontal comprehensive machining centers and flexible manufacturing systems (FMS). It combines a powerful hydraulic amplification mechanism with a precise mechanical structure, aiming to meet various demanding requirements ranging from heavy cutting to precision machining, ensuring high efficiency, high precision, and high reliability.

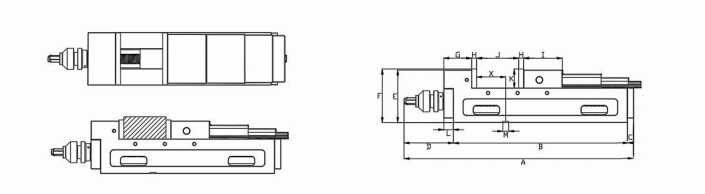

Design and Composition

Solid body: It is made by casting a high tensile strength spherical graphite cast iron (FCD600) in one piece, ensuring structural rigidity and strong resistance to deformation.

Hardening treatment: The sliding surface of the handle and the jaws of the clamp have undergone hardening heat treatment, with a hardness of over HRC42°, ensuring excellent wear resistance and long service life.

Patent pressure mechanism: The core is a patented rapid pressure increase and high clamping force hydraulic mechanism.

Integrated fixed jaw: The body and the fixed jaw are of an integrated structure, fundamentally preventing the backward tilt during clamping and the overturning of the jaw body.

Anti-scraping design: A specially designed anti-scraping structure effectively prevents iron filings from entering the internal transmission components, facilitating cleaning and extending the service life.

Core Function

Superior Clamping Force: The patented hydraulic mechanism can provide a maximum clamping force of up to 5,000 kgf, providing a solid foundation for heavy cutting operations.

Prevent work from floating: A built-in anti-floating transmission mechanism is incorporated. When clamping, it generates a downward force, effectively suppressing the upward floating of the workpiece and the movable jaw, ensuring processing stability.

Clamping force preset and consistency: Equipped with an adjustable "adjusting stop ring", the operator can easily preset the required clamping force. The system ensures that each clamping operation will repeat the exact same precise force, which is crucial for automated production.

Quick operation: The hydraulic design enables rapid clamping and releasing, significantly enhancing the efficiency of component replacement.

Application scenario

Precision mechanical processing: Suitable for milling, drilling, tapping and other processes that require high repeatability positioning accuracy.

Re-cutting processing: With its strong clamping force, it is capable of performing heavy-duty rough machining and roughing on materials such as steel and cast iron.

Automated production line (FMS): The clamping force can be preset and consistent, and it works in conjunction with rapid movements, making it a reliable choice for unmanned or flexible manufacturing units.

Multi-station configuration: Suitable for batch production or processing of complex parts where multiple vices need to be used simultaneously for clamping.

Challenges and Solutions

Challenge: Vibration and workpiece displacement caused by re-cutting

Solution: The 5000kgf high clamping force, combined with the integrated body and anti-floating mechanism, forms a highly rigid clamping system that effectively absorbs vibrations and prevents the workpiece from loosening.

Challenge: Inconsistent clamping force during automated production affects quality

Solution: The unique preset pressure regulating ring ensures that the clamping force is exactly the same for each operation and each workstation, guaranteeing the stability of mass production.

Challenge: Processing iron filings affects accuracy and equipment lifespan

Solution: The comprehensive anti-scuffing design protects the precise hydraulic and transmission components, reduces maintenance requirements, and ensures long-term accuracy.

The MC series precision hydraulic vise is not a common manual fixture. It is an engineering solution specifically designed to address the challenges of modern high-end mechanical processing. It combines an extremely strong clamping force (5000 kgf), precise anti-floating control, repeatable clamping force presets, and a sturdy and durable structure. It is the ideal choice for heavy cutting processing and automated production environments that prioritize high efficiency, high precision, and high reliability.