Pob kws Radius Mill rau Nickel-Based High-Temp Alloys

COV KHOOM PIAV TXOG

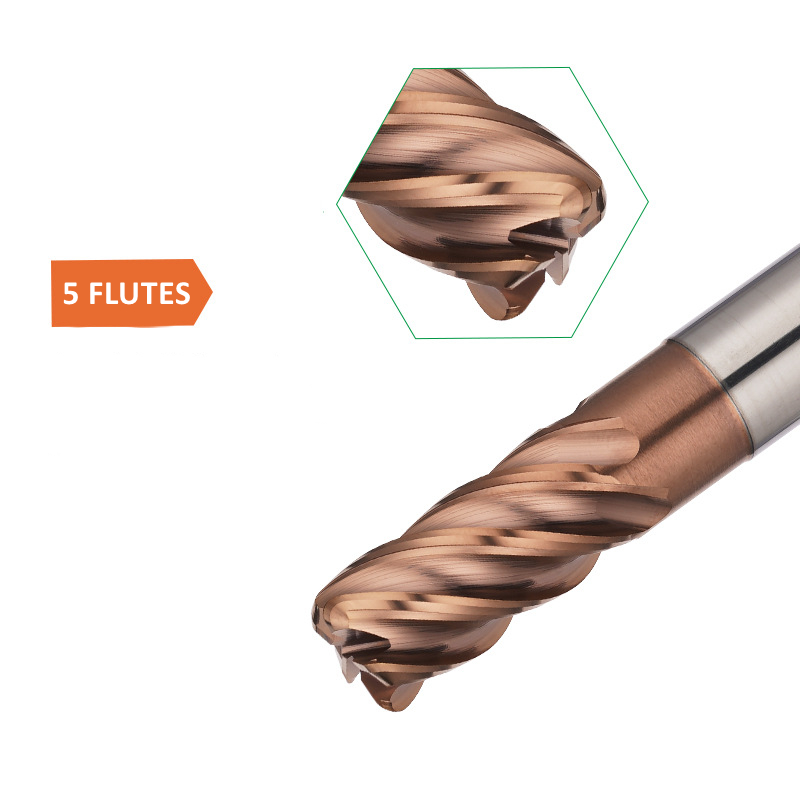

Titanium yog ib yam khoom siv uas nyuaj rau tshuab, tshwj xeeb tshaj yog nyob rau hauv cov cuab yeej siv zog, xws li cov uas cuam tshuam nrog High Efficiency Milling (HEM). Lub tshuab txiav ces kaum no yog siv tshwj xeeb rau kev ua cov ntaub ntawv hauv kev lag luam aviation. Nws siv cov hlau tungsten uas xa tuaj thiab muaj lub neej ua haujlwm ntev.

COV LUS QHIA TXOG KEV SIV HAUV COV ROOJ SIB THAM

Titanium alloy TC18-21, ferrite, high-nickel alloy saum toj no 35%, high-temperature stainless hlau, nickel-chromium-cobalt thiab lwm yam nyuaj-rau-txiav high-strength titanium alloys, high-temperature alloy cov ntaub ntawv.

Tus qauv tsim 5-flute yog 30% -40% sai dua li lub tshuab txiav 3-flute / 4-flute

Tsim Kev Av Qeeg/Kev Tshem Tawm Hlau Siab Heev/Kev Nyuaj Siab Sab Hauv Qis

| Lub raj nplaim txoj kab uas hla | D6-D12 | Lub raj ntev | 8-24 hli |

| Hom raj nplaim | Helical | Khoom siv | Tungsten qib siab |

| Txheej | Yog | Hom | MSK |

| Kev Ua Haujlwm Ntau Yam | Cov ntaub ntawv nyuaj txiav xws li titanium alloys, superalloys, ferrites, nickel bodies, high-temperature stainless steels, thiab nickel-chromium-cobalt | ||

| Cov Tshuab Siv Tau | Cov tshuab milling, CNC machining chaw, lub computer gongs, engraving tshuab | ||

NTAUB NTAWV

1. Tshwj xeeb rau Titanium / superalloy nyuaj-rau-txiav cov ntaub ntawv

Nruab nrog lubricating siab thiab qis txhuam coefficient txheej kom txo qis kev ntxhov siab sab hauv ntawm cov khoom ua tiav.

2. Lub raj nplaim geometry

Kev tsim qauv geometric zoo heev 5-hniav U-groove tuaj yeem ua rau qhov chaw sib cuag nrog cov khoom siv uas yuav tsum tau ua tiav, thaum ua kom lub cuab yeej ruaj khov thiab ua kom qhov roughness ntawm qhov chaw zoo heev.

3. Cov hlau tungsten uas tau xa tawm

Qhov tseeb ntawm qhov kam rau siab ntawm shank yog H5, tsim tshwj xeeb rau cov kab ke clamping shank siab.

4. Tsim qauv Chamfer

Ua kom yooj yim rau clamp.

5. Tsim Kev Tiv Thaiv Av Qeeg

Kev tshem tawm cov hlau sai heev, kev ntxhov siab sab hauv qis, 30% -40% sai dua li cov tshuab txiav 3-hniav/4-hniav ib txwm muaj

Daim Ntawv Thov:

Aerospace, tub rog, khoom siv kho tshuab, tsheb, kev sib txuas lus hluav taws xob tshwj xeeb thiab lwm yam teb

Cov Lus Cim ntawm Tus Neeg Yuav Khoom:

1. Ua ntej siv cov cuab yeej, thov ntsuas qhov deflection ntawm cov cuab yeej. Thaum qhov tseeb ntawm cov cuab yeej deflection tshaj 0.01 hli, thov kho nws ua ntej txiav.

2. Qhov ntev ntawm cov cuab yeej uas tawm ntawm lub chuck luv dua, qhov zoo dua. Yog tias cov cuab yeej tawm ntev dua, qhov ceev, qhov nrawm ntawm kev pub thiab qhov ntau ntawm kev txiav yuav tsum tau txo qis.

3. Thaum lub sijhawm txiav, yog tias muaj kev co lossis suab tsis zoo, thov txo qhov ceev thiab qhov txiav kom txog thaum qhov xwm txheej zoo dua.

4. Cov hlau txias zoo dua yog siv tshuaj tsuag thiab cua tshuab, uas tuaj yeem txhim kho kev siv ntawm lub tshuab txiav. Tsis pom zoo kom siv cov titanium alloys thiab lwm yam superalloys.