HSSCO Kub Melt Laum Tshwj Xeeb Siv Tap M3 M4 M5 M6 M8 M10 M12

KHOOM PLIG

Cov laum kub yaj ua kom muaj cua sov los ntawm kev sib hloov ceev thiab axial siab sib txhuam, plasticizes cov khoom, thiab tib lub sij hawm xuas nrig ntaus thiab tsim cov bushing txog 3 npaug ntawm cov khoom siv raw.Precision, high-strength threads.

Nws zoo daws qhov teeb meem ntawm tapping nyias phaj, square tube thiab round tube qhov chaw thiab txhim kho kev sib txuas lub zog;nws tsis tas yuav siv qhov yooj yim qhov chaw vuam, txiv ntseej thiab ntxhua khaub ncaws, uas ua kom yooj yim rau cov txheej txheem ua tiav, thiab muaj kev ua haujlwm siab, yog li txo qhov seem ntawm cov khoom thiab txuag nyiaj.Tus nqi tsim khoom.

Kev siv cov kub-melt drilling yog txheej txheem tshiab ntawm kev txuag hluav taws xob thiab kev tiv thaiv ib puag ncig.Kev siv tshuab tshiab.

Nws tuaj yeem ntsia tau rau ntawm qhov chaw machining, CNC tshuab cuab yeej, tshuab milling, lub rooj ntev zaum xyaum, tes xyaum, drilling tshuab thiab lwm yam khoom siv.

Nws yog tsim rau kev ua ntau yam ntaub ntawv hlau nrog ib txoj kab uas hla ntawm 1.8-32MM thiab phab ntsa thickness ntawm 0.5-12.5MM.Tom qab ua tiav, lub voj voog tus thawj coj yuav raug tsim rau ntawm qhov chaw ntawm lub workpiece.

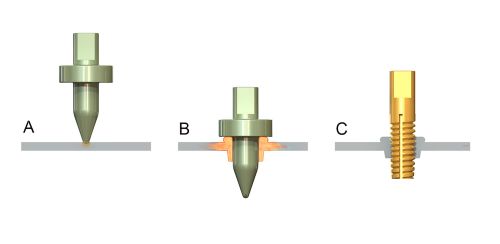

Qhov saum npoo ntawm lub workpiece yog tiaj tus tom qab lub tiaj tiaj-hom kub drilling txheej txheem, uas yog tsim los ntawm flattening tus thawj annular los ntawm kev txiav ntug nyob rau hauv pem hauv ntej ntawm lub shank.

Vim hais tias lub thickness ntawm lub thoob tom qab kub yaj drilling txheej txheem yog nyias nyias, cov pa tej kais dej tsis tau siv thaum tapping threads, tab sis txias extrusion kais siv, thiab cov extruded threads muaj zog heev., High hardness tsis yooj yim rau hnav thiab txhim khu lub zog torque.

Qhov kub yaj laum yuav tsim kom muaj qhov kub thiab txias thaum lub sijhawm ua haujlwm, uas yuav hloov cov cua sov mus rau qhov ntxaiv ntawm lub laum rig thiab ua rau muaj kev puas tsuaj rau lub fixture.

Lub tshuab-clamping cuab yeej tuav nrog tshwj xeeb tshav kub dissipation muaj nuj nqi yog siv ua ke, uas tsis tsuas yog txhim kho qhov raug thiab tiv thaiv cov cuab yeej, tab sis kuj zoo dissipate tshav kub.Lub clamping ib feem ntawm lub txias tis kov yuav xaiv raws li txoj kev sib txuas ntawm cov cuab yeej siv tshuab, thiab cov chuck tuaj yeem xaiv raws li qhov loj ntawm qhov kub laum.

Vim tias qhov kev ua tau zoo ntawm cov ntsiab lus kub-kub ntawm qhov kub-melt laum, nws tuaj yeem tsis tsuas yog laum high-speed steel, bearing alloy steel thiab high-hardness workpieces tom qab quenching, tab sis kuj cov txheej txheem xws li stainless hlau, qis- carbon hlau, thiab tooj liab alloys.

Siv dav hauv kev tsim tsheb thiab maus taus, rooj tog, kev tsim kho, kho kom zoo nkauj, tshuab cuab yeej machinery, aerospace, electronics, khoom siv hluav taws xob, dej, rhawv, nkoj tsim thiab automation khoom, thiab lwm yam.