Cov Cermet Zoo Zoo Rau Kev Ua tiav Hlau Thiab Stainless

COV KHOOM PIAV TXOG

Ntawm qhov kawg ntawm lub kais (xov kais) yog lub laum me ntsis, uas yog lub kais ua haujlwm siab (xov kais) rau kev tho thiab tapping tas mus li kom ua tiav cov txheej txheem ib zaug.

Cov yam ntxwv

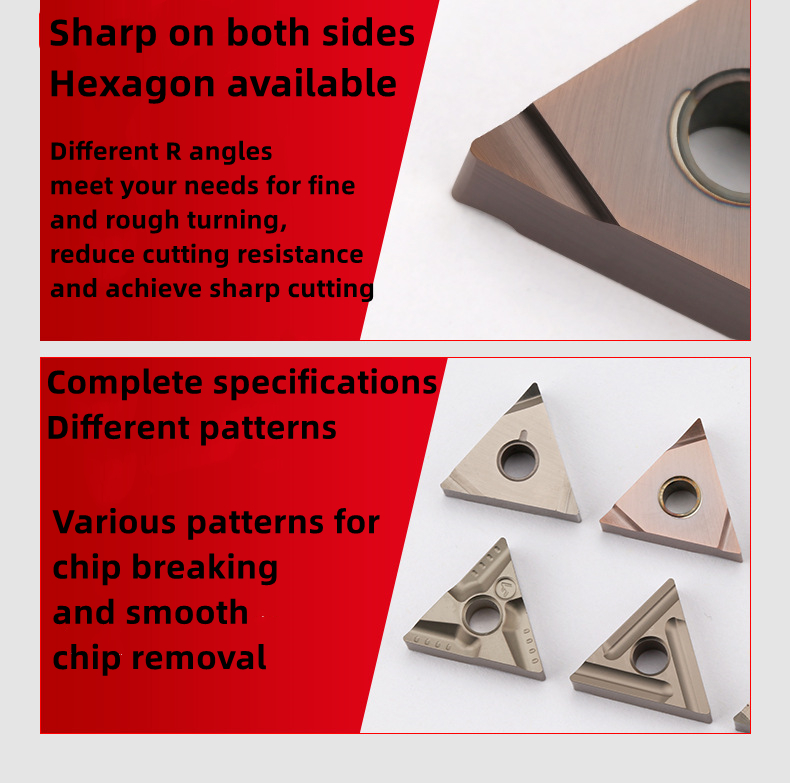

1. Ob sab ntse, Hexagon muaj

Cov kaum sab xis R sib txawv ua tau raws li koj qhov kev xav tau tig zoo thiab ntxhib, Txo qhov tsis kam txiav thiab ua tiav kev txiav ntse

2. Cov qauv sib txawv

Cov lus qhia tiav thiab ntau yam qauv rau kev tawg chips thiab kev tshem tawm cov chips du

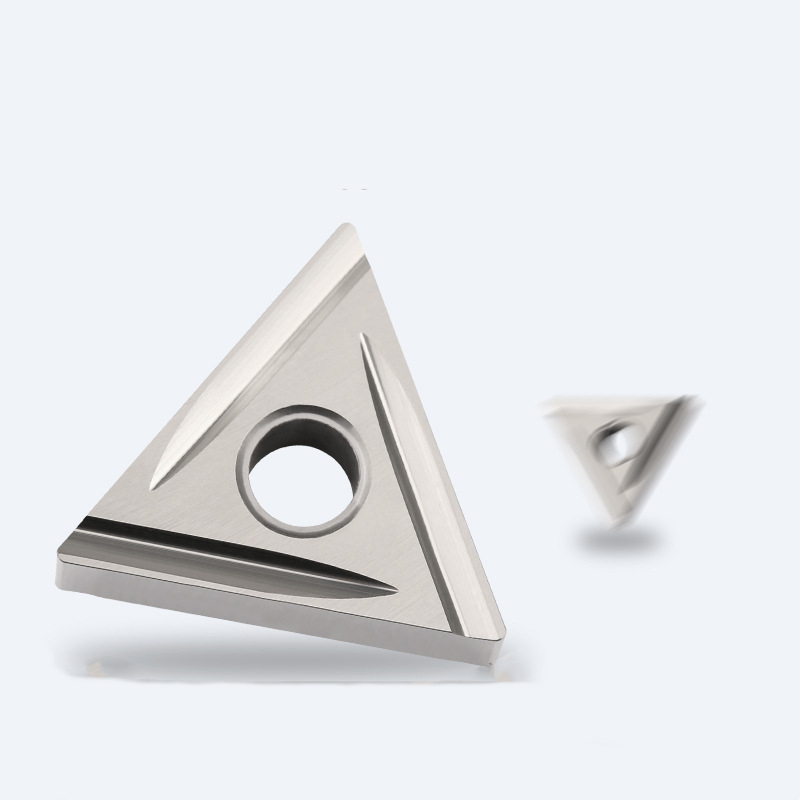

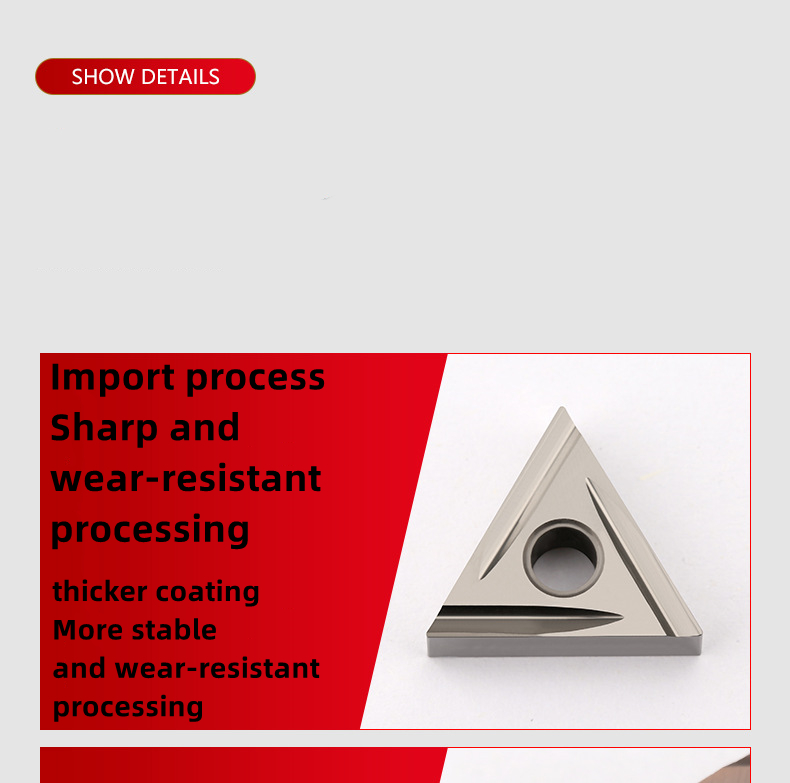

3. Cov txheej txheem ntshuam

Ntse thiab hnav-resistant, txheej tuab dua.

Kev ua haujlwm ruaj khov dua thiab hnav-resistant

Tshwj xeeb rau cov khoom siv ceramics, hnav-resistant thiab ruaj khov, siab dua hardness.

| Hom | MSK | Hom | Cov Cuab Yeej Milling |

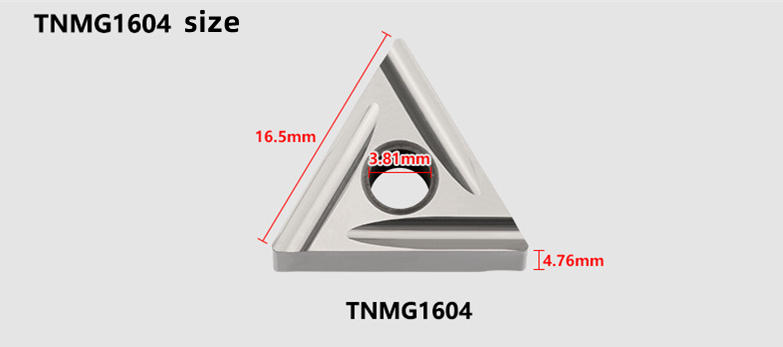

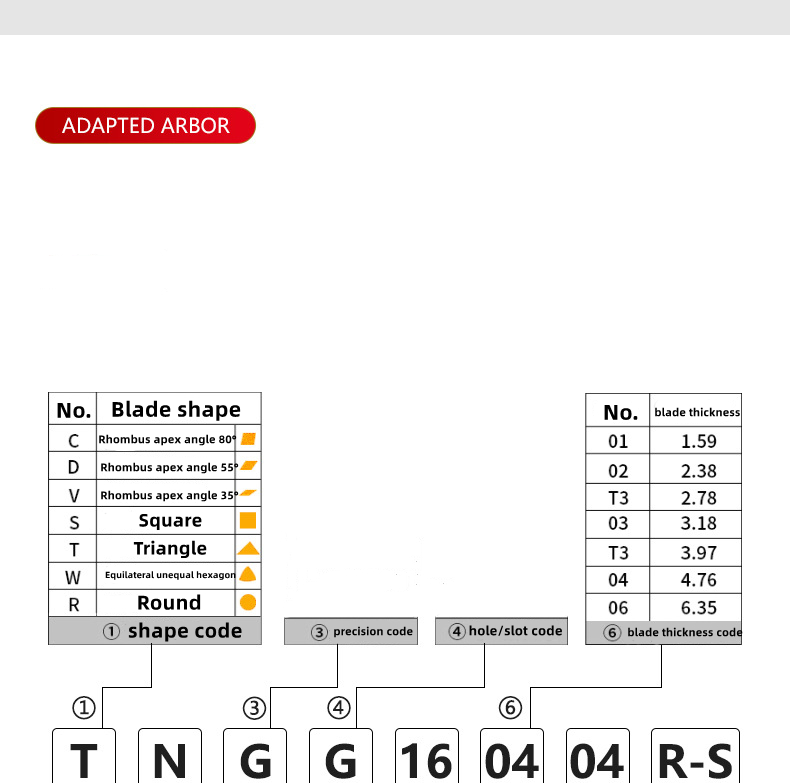

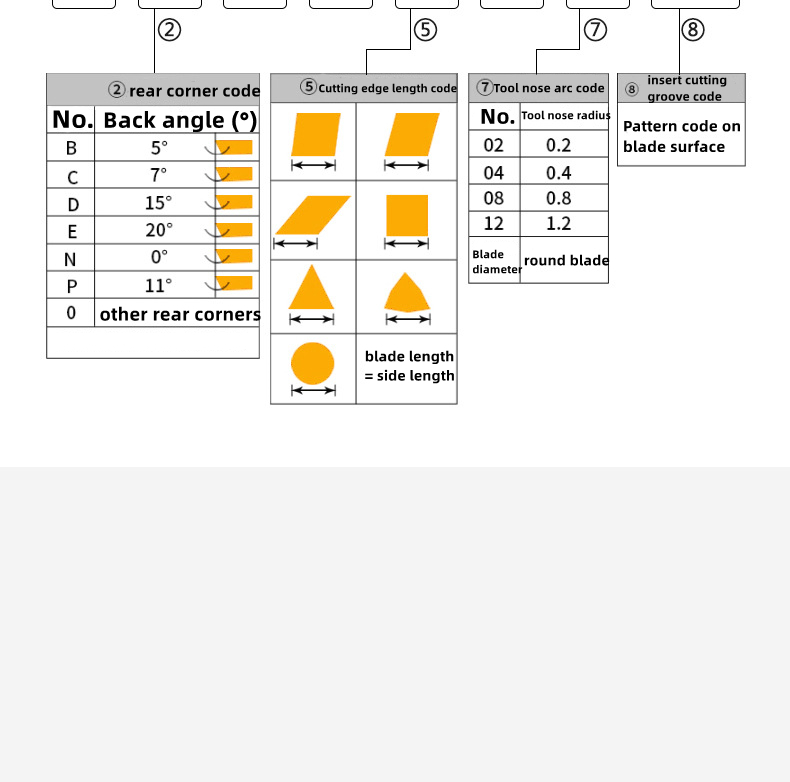

| Lub Npe Khoom | Cov Carbide Inserts | Qauv | TNGG160402 |

| Khoom siv | Cov Khoom Siv Ua Los Ntawm Av nplaum | Pob khoom | Lub thawv yas |

DAIM NTAWV CEEV

Kev tshuaj xyuas cov teeb meem uas tshwm sim ntau zaus

1. Kev hnav lub ntsej muag rake: (qhov no yog hom kev siv ua feem ntau)

Cov Teeb Meem: Kev hloov pauv maj mam ntawm qhov loj ntawm cov khoom ua haujlwm lossis txo qhov tiav ntawm qhov chaw.

Vim li cas: Cov khoom siv riam tsis haum, thiab qhov txiav ntau dhau.

Kev Ntsuas: Xaiv cov khoom siv tawv dua, txo qhov txiav ntau npaum li cas, thiab txo qhov ceev ntawm kev txiav.

2. Teeb meem kev sib tsoo: (kev ua haujlwm tsis zoo)

Cov Teeb Meem: Kev hloov pauv sai sai ntawm qhov loj me ntawm workpiece lossis qhov chaw tiav, ua rau muaj hluav taws xob ntawm qhov chaw.

Vim li cas: kev teeb tsa tsis raug, kev xaiv cov khoom siv hniav tsis raug, qhov workpiece tsis ruaj khov, kev clamping hniav tsis ruaj khov. Kev Ua: Tshawb xyuas cov txheej txheem machining, xws li txo qhov ceev ntawm kab thiab hloov mus rau qhov ntxig uas tiv taus hnav dua.

3. Poob lawm loj heev: (tsis zoo kiag li)

Kev cuam tshuam: qhov tshwm sim sai thiab tsis paub tseeb, ua rau cov khoom siv tuav cuab yeej pov tseg lossis cov khoom ua haujlwm tsis zoo thiab pov tseg. Ua rau: Cov txheej txheem ua haujlwm tau teeb tsa tsis raug, thiab cov khoom siv cuab yeej co lossis hniav tsis tau teeb tsa rau hauv qhov chaw.

Kev Ntsuas: Teem cov txheej txheem machining tsim nyog, txo qhov pub noj thiab txo cov chips kom xaiv cov machining inserts sib xws.

Ntxiv dag zog rau lub rigidity ntawm workpiece thiab hniav.

3. Ntug ua tiav

Kev Cuam Tshuam: Qhov loj ntawm cov khoom ua haujlwm tawm tsis sib xws, qhov chaw tiav tsis zoo, thiab qhov chaw ntawm cov khoom ua haujlwm tau txuas nrog fluff lossis burrs. Vim li cas: Qhov ceev txiav qis dhau, qhov pub tsawg dhau thiab cov hniav tsis ntse txaus.

Kev Ntsuas: Ua kom qhov ceev ntawm kev txiav thiab siv cov ntxig ntse dua rau kev pub.