High Quality M35 Machine Spiral Taps DIN 376 Spiral Thread Taps

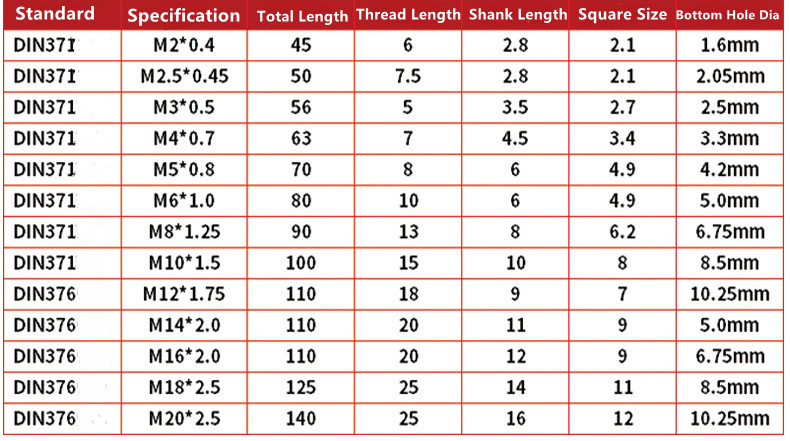

Analysis on the Problem of Premature Breaking of Taps;Reasonable selection of taps: The tap type must be reasonably determined according to the workpiece material and the depth of the hole;The bottom hole diameter is reasonable: for example, M5*0.8 should choose 4.2mm bottom hole. Misuse of 4.0mm will cause breakage.;Workpiece material problem: the material is impure, there are excessive hard points or pores in the part, and the tap instantly loses balance and breaks;Choose flexible chuck: set a reasonable torque value with a chuck with torque protection, which can prevent breaking when stuck;Synchronous compensation tool holder: it can provide axial micro-compensation for the non-synchronization of speed and feed while rigid tapping;Poor quality of cutting fluid: Problems with the quality of cutting fluid and lubricating oil will affect the accuracy of the thread and the life of the tap;Cutting speed feed: too small thread accuracy is poor, too high will break the tap directly, depending on the master’s experience;Blind hole hits the bottom hole: When machining the blind hole thread, the tap is about to touch the bottom of the hole, and the operator does not realize it

Excellent selection of materials

Using excellent cobalt-containing raw materials, it has the advantages of higher toughness, good hardness and wear resistance.

Wide range of applications

Cobalt-containing straight flute taps can be used for drilling of different materials, with a complete range of products.