High-Quality EMR Radius Milling Bar For Precise Design

This EMR round nose milling bar is designed for multi-faceted machining, excelling in roughing, digging, jacking, EMR Radius Cutting and step/trapezoidal surface machining. Constructed with hardened, vibration-resistant alloy steel, it offers more stable and efficient high-power milling; its extra-long, effective clearance design significantly reduces friction and increases chip clearance, making machining smoother and more reliable.

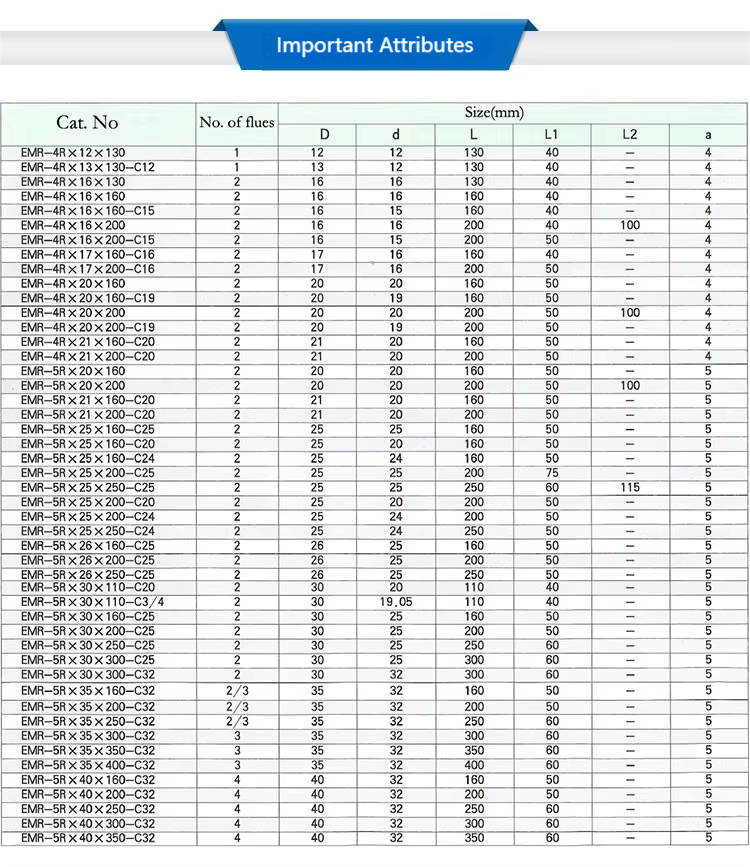

Important Attributes

Product Features

Powerful cutting capability; its rotation and feed rate are three times that of ordinary end mills; economical inserts; high cost-performance ratio.

1.The insert and bar fit together tightly to effectively reduce vibration and prevent wear.

2.Precision chip removal groove design

Adequate chip removal reduces blade wear and tool breakage caused by poor chip removal during processing

3.The effect of installing the milling bar on the tool holder

Advantages

1. All-rounder: Suitable for rough machining, excavation, cutting, and processing of various complex shapes such as step surfaces and trapezoidal surfaces. With multiple functions in one rod, it enhances processing adaptability.

2. More shock-resistant and efficient: Made of special hardened shock-resistant alloy steel, it effectively suppresses cutting vibration, ensuring stable and efficient operation even during heavy milling, significantly enhancing processing efficiency and surface quality.

3. Strong chip avoidance and clearance: The optimally designed ultra-long effective chip avoidance structure not only prevents interference and friction between the tool holder and the workpiece but also provides a larger chip clearance space, making chip removal smoother and the processing cleaner and more reliable.

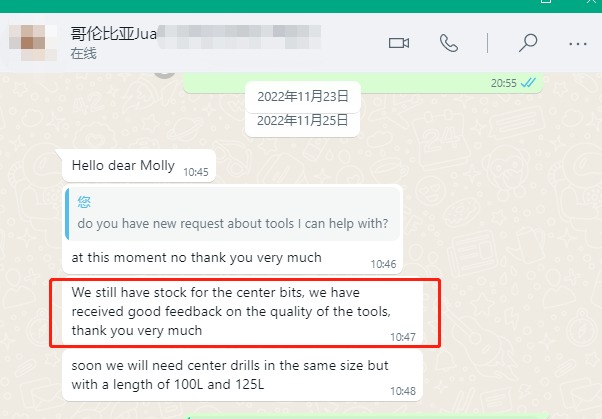

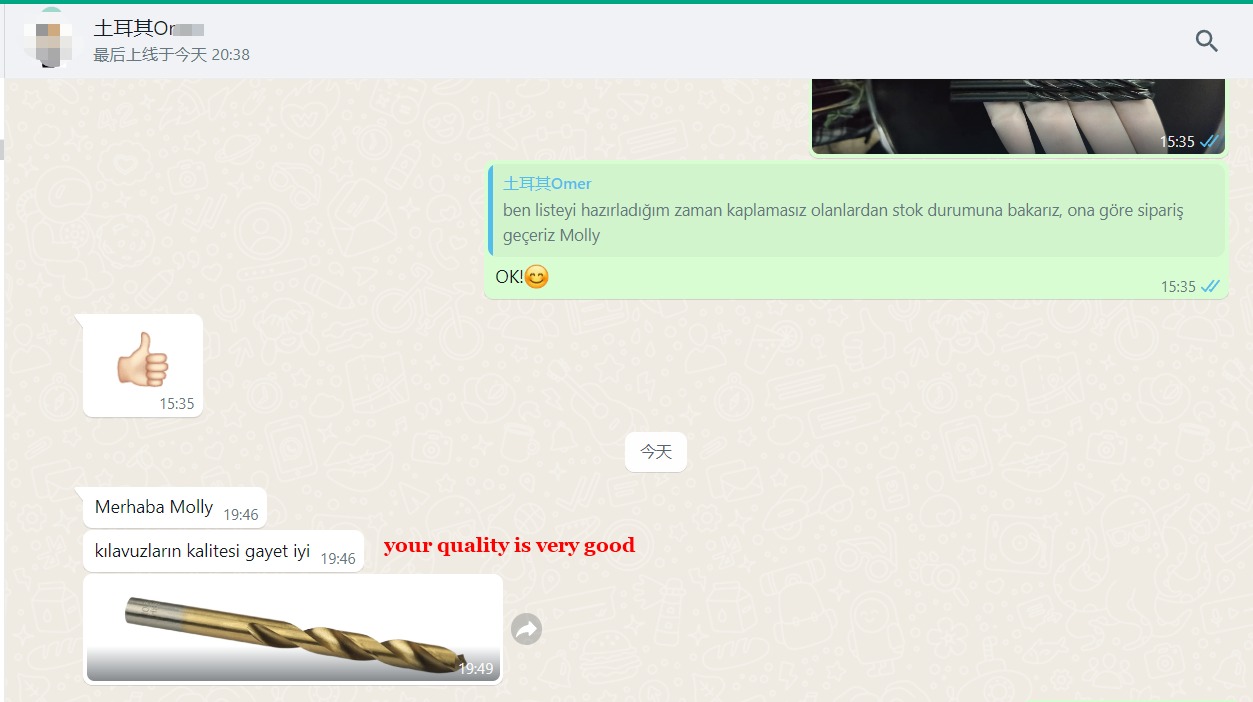

Why Choose Us

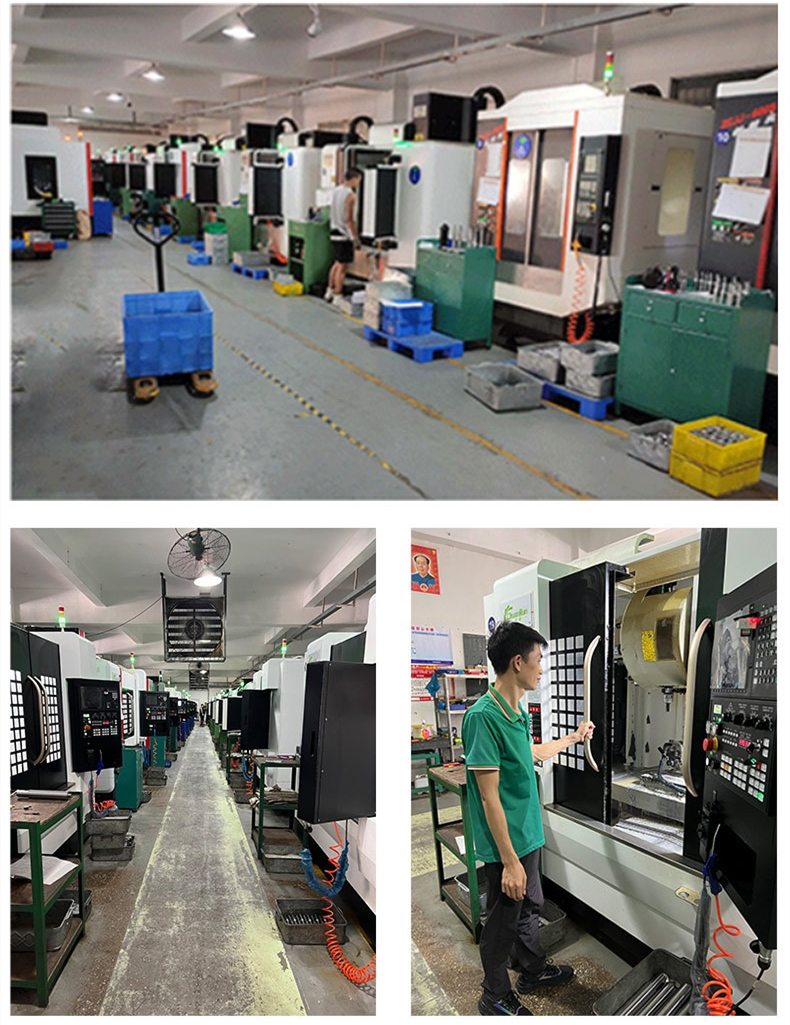

Factory Profile

FAQS

1.Q: In which specific processing scenarios is the EMR round-nose milling cutter holder suitable?

A: It is a multi-functional milling cutter holder, specially designed for complex working conditions, and is widely applicable to rough machining, excavation, cutting, as well as efficient milling of various shapes such as step surfaces and trapezoidal surfaces.

2. Q: How does this tool holder ensure stability during heavy processing?

A: The tool holder is made of specially designed anti-vibration alloy steel and has undergone hardening treatment. This can effectively suppress cutting vibration, ensuring stable processing even during heavy-duty milling, thereby enhancing processing efficiency and surface quality.

3. Q: What benefits does the "effective void avoidance long" design bring to actual processing?

A: This design mainly has two major advantages: First, it avoids interference and friction between the tool holder body and the workpiece surface, protecting both the workpiece and the tool; Second, it provides a larger chip holding space, making chip removal smoother and reducing the risk caused by chip blockage.

4. Q: Can it be used to enhance the efficiency of rough machining?

A: Absolutely possible. Its outstanding shock resistance and rigidity design enable it to withstand powerful cutting with large cutting depths and high feed rates, making it a reliable choice for efficient rough machining and excavation machining.

5. Q: What materials of workpieces is this tool holder suitable for processing?

A: The tool holder itself is made of high-strength alloy steel and is suitable for processing various metal materials. Its outstanding seismic resistance and strength make it perform particularly well under harsh conditions such as processing harder materials or intermittent cutting.