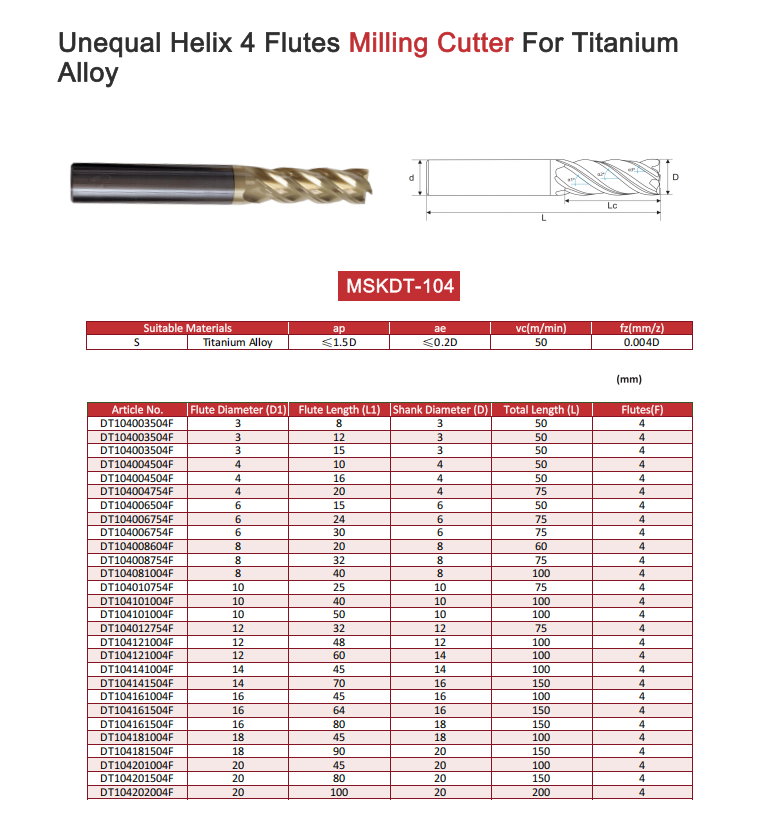

High-Performance Titanium Alloy Special End Mills For CNC Precision Machining

This titanium CNC end mill is crafted from robust carbide, achieving a hardness of HRC70 (the hardness rating for carbide end mills). Its Unequal Helix 4 Flutes design makes it exceptionally effective at machining high-hardness materials such as stainless steel and high-temperature alloys, making it a high-performance titanium end mill. We offer a variety of coating options, customization services, and expert technical support to ensure optimal machining results.

Important Attributes

| Product Name: | Helix Angle End Mill with Unequal Splits |

| Hardness: | HRC70 |

| Brand: | MSK |

| MOQ: | 5 pc |

| Number of Cuttings: | 4 (Flute) |

| Diameter: | D1-D20mm |

| Length: | 50/60/75/100/150/200 mm |

| Material: | Carbide |

| Processing Materials: | Aerospace, Stainless Steel, High Temperature Alloy |

Product Features

1.Coating:Titanium

The high-density coating is excellent in wear resistance and effective in heat insulation

2.Spiral large chip removal, smooth and non-stick cutting

Applicable models: CNC machining centers, engraving machines, precision engraving machines, and other high-speed machines.

3.Fully ground helix angle ensures smooth chip removal.

Prevent chip buildup and sticking to the blade, thus improving efficiency.

Advantages

1. Superior Durability and Long Lifespan: Utilizing a composite material of tungsten carbide (hard alloy) and high-speed steel, it combines high hardness and toughness, offering strong wear resistance and maintaining sharpness for extended periods, reducing frequent tool replacement costs.

2. Diverse Coatings and Wide Adaptability: Offers a variety of coating options including Altin, TiAlN, TiCN, and Tin. The optimal coating can be selected based on the material being machined (e.g., stainless steel, alloy steel, high-temperature alloys), significantly improving oxidation resistance and high-temperature performance, extending tool life.

3. High-Efficiency Cutting and Stable Reliability: The 4-flute design balances chip removal efficiency and cutting stability. Combined with a hardness of up to 68 HRC, it is suitable for high-speed cutting of high-strength materials (such as stainless steel), improving machining efficiency and surface finish.

4. Fully Customizable and Flexible: Supports deep OEM/ODM customization. Tool size, coating, and cutting edge shape can be customized according to customer needs to meet the personalized requirements of special processes or bulk purchases.

Why Choose Us

Factory Profile

About Us

Founded in 2015, MSK (Tianjin) International Trading CO.,Ltd has grown continuously and passed Rheinland ISO 9001 authentication. With German SACCKE high-end five-axis grinding centers, German ZOLLER six-axis tool inspection center, Taiwan PALMARY machine and other international advanced manufacturing equipment, we are committed to producing high-end, professional and efficient CNC tool. Our specialty is the design and manufacturing of all kinds of solid carbide cutting tools: End mills, drills, reamers, taps and special tools. Our business philosophy is to provide our customers with comprehensive solutions that improve machining operations, increase productivity, and reduce costs. Service + Quality + Performance. Our Consultancy team also offers production know-how, with a range of physical and digital solutions to help our customers navigate safely into the future of industry 4.0. For more in-depth information on any particular area of our company, please explore our site or use the contact us section to reach out to our team directly.

FAQS

Q1: Who are we?

A1: Established in 2015, MSK (Tianjin) Cutting Technology Co., Ltd. has been continuously growing and expanding, and has passed the Rheinland ISO 9001

Identity verification. Equipped with international advanced manufacturing facilities such as the German SACCKE high-end five-axis grinding center, the German ZOLLER six-axis tool inspection center, and Taiwan handheld consoles, we are committed to producing high-end, professional and efficient CNC tools.

Q2: Are you a trading company or a manufacturer?

A2: We are a factory of hard alloy tools.

Q3: Could you send the products to our freight forwarder in China?

A3: Yes, if you have a freight forwarder in China, we would be more than happy to send the products to him/her.

Q4: What payment terms can be accepted?

A4: Usually, we accept wire transfers.

Q5: Do you accept OEM orders?

A5: Yes, we can offer OEM and customization services. We also provide label printing services.

Q6: Why did you choose us?

A6:1) Cost control - Purchasing high-quality products at appropriate prices.

2) Quick response - Within 48 hours, a professional will provide you with a quotation and solve your problem.

3) High quality - The company has always sincerely proven that the products it provides are 100% of high quality.

4) After-sales service and technical guidance - The company provides after-sales service and technical guidance based on the requirements and needs of customers.