Good Quality HRC 55 Solid Carbide Reamer for CNC Machine

Introducing our cutting-edge hard alloy hinge cutter, boasting a remarkable hardness of HRC55. This tool is meticulously engineered to provide exceptional durability and precision in a wide range of applications. The HRC55 rating ensures that the blade maintains its sharpness over extended usage, guaranteeing consistent and reliable performance. Whether you're working on intricate woodworking projects or demanding metal applications, this hinge cutter is designed to meet the highest standards, making it an indispensable tool for craftsmen and professionals alike. Invest in precision and longevity with our HRC55 hard alloy hinge cutter.

| Flute diameter(d) | Flute length(L) | Total length(L) | Shank diameter(D) | Number of flutes(F) |

| 1 | 15 | 50 | 1 | 4 |

| 1.5 | 15 | 50 | 1.5 | 4 |

| 2 | 15 | 50 | 2 | 4 |

| 2.5 | 15 | 50 | 2.5 | 4 |

| 3 | 20 | 50 | 3 | 4 |

| 3.5 | 20 | 50 | 3.5 | 4 |

| 4 | 20 | 50 | 4 | 4 |

| 4.5 | 22 | 50 | 4.5 | 4 |

| 5 | 22 | 60 | 5 | 4 |

| 5.5 | 25 | 60 | 5.5 | 4 |

| 6 | 25 | 60 | 6 | 6 |

| 7 | 28 | 69 | 7 | 6 |

| 8 | 28 | 70 | 8 | 6 |

| 9 | 32 | 80 | 9 | 6 |

| 10 | 32 | 80 | 10 | 6 |

| 11 | 35 | 80 | 11 | 6 |

| 12 | 35 | 80 | 12 | 6 |

| 13 | 50 | 100 | 13 | 6 |

| 14 | 50 | 100 | 14 | 6 |

| 15 | 50 | 100 | 15 | 6 |

| 16 | 50 | 100 | 16 | 6 |

| 18 | 50 | 100 | 18 | 6 |

| 20 | 50 | 100 | 20 | 6 |

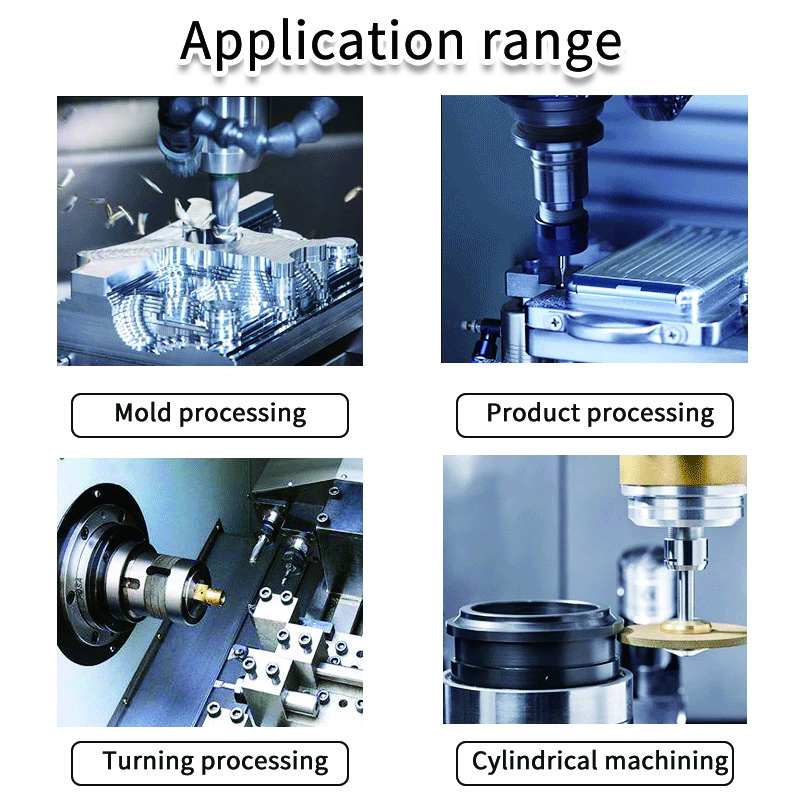

A reamer is a versatile tool widely used in metalworking for cutting and shaping a variety of metal workpieces. The tool consists of a sturdy blade and a handle that makes precise cuts on metal surfaces by manually or mechanically reciprocating the blade.

This tool plays a pivotal role in various industries such as manufacturing, construction and maintenance. Its wide range of applications makes it an indispensable asset in the metalworking process, providing vital support for tasks that require precision, efficiency and versatility.

| Brand | MSK | Packing | Plastic box or other |

| Material | 20CrMnTi | Usage | Cnc Milling Machine Lathe |

| Customized support | OEM,ODM |

Type | NBT-ER |

What customers say about us

FAQ

Q1: Who are we?

A1: MSK (Tianjin) Cutting Technology Co., Ltd. was established in 2015. It has been growing and has passed Rheinland ISO 9001

With international advanced manufacturing equipment such as SACCKE high-end five-axis grinding center in Germany, ZOLLER six-axis tool testing center in Germany, and PALMARY machine tools in Taiwan, it is committed to producing high-end, professional, efficient and durable CNC tools.

Q2: Are you trading company or manufacturer?

A2: We are manufacturer of carbide tools.

Q3: Can you send the product to our forwarder in China?

A3: Yes, if you have a forwarder in China, we are happy to send the products to him/her.

Q4: What payment terms can be accepted?

A4: Usually we accept T/T.

Q5: Do you accept OEM orders?

A5: Yes, OEM and customization are available, we also provide custom label printing service.

Q6: Why choose us?

1) Cost control - purchase high-quality products at an appropriate price.

2) Quick response - within 48 hours, professionals will provide you with quotations and solve your doubts

consider.

3) High quality - the company always proves with a sincere heart that the products it provides are 100% high-quality, so that you have no worries.

4) After-sales service and technical guidance - we will provide one-on-one customized service and technical guidance according to your requirements.

The reamer, an indispensable tool in precision machining, plays a pivotal role in achieving accurate dimensions and smooth finishes in machined holes. Comprising a simple yet sophisticated design, the reamer exemplifies the meticulous craftsmanship demanded by various industries. Let's delve into the intricacies of this tool, exploring its functions, applications, and significance in the world of machining.

Design and Components:

A reamer typically consists of a series of cutting edges arranged along a cylindrical body. The cutting edges, often in the form of straight or helical flutes, are designed to remove material gradually as the tool is rotated. The body of the reamer is crafted from high-speed steel, carbide, or other durable materials, ensuring longevity and resilience under the demanding conditions of machining.

Functionality:

The primary function of a reamer is to refine and size a previously drilled hole. Unlike drills that create holes, reamers provide the finishing touch, ensuring the hole meets precise dimensional requirements. They remove any irregularities left by the drilling process, improving the accuracy and surface finish of the machined hole. Reamers come in various types, including straight-fluted, spiral-fluted, and adjustable, each designed to cater to specific machining needs.

Applications:

The versatility of reamers finds application in a multitude of industries, including aerospace, automotive, medical, and manufacturing. In aerospace and automotive engineering, where precision is paramount, reamers are instrumental in creating holes for critical components such as engine parts and fasteners. In the medical field, where implant manufacturing demands utmost precision, reamers contribute to creating holes for prosthetic components.

Precision Machining:

One of the key attributes of reamers is their ability to achieve tight tolerances. Machinists rely on these tools to fine-tune hole dimensions within extremely narrow limits. The precision afforded by reamers is crucial in industries where components must fit together seamlessly, ensuring optimal functionality and structural integrity.

Types of Reamers:

The diverse requirements of machining have led to the development of various types of reamers. Straight-fluted reamers are well-suited for general-purpose applications, while spiral-fluted reamers excel in tasks requiring efficient chip removal. Adjustable reamers offer flexibility in achieving different hole sizes without the need for multiple tools. Each type caters to specific machining scenarios, showcasing the adaptability of reamers in various industrial settings.

Challenges and Considerations:

While reamers are invaluable in achieving precision, machinists must consider factors such as tool alignment, speed, and feed rates to ensure optimal performance. Maintaining sharp cutting edges is essential for achieving consistent results, and periodic inspections and regrinding become part of the routine maintenance to uphold the effectiveness of the tool.

In conclusion, the reamer stands as a testament to the precision demanded by modern machining processes. Its ability to refine and size machined holes with accuracy and finesse makes it a cornerstone in industries where quality and precision are non-negotiable. As technology advances, the reamer continues to evolve, adapting to the ever-changing landscape of manufacturing and remaining a vital tool in the pursuit of excellence in precision machining.