Chamfer Tool

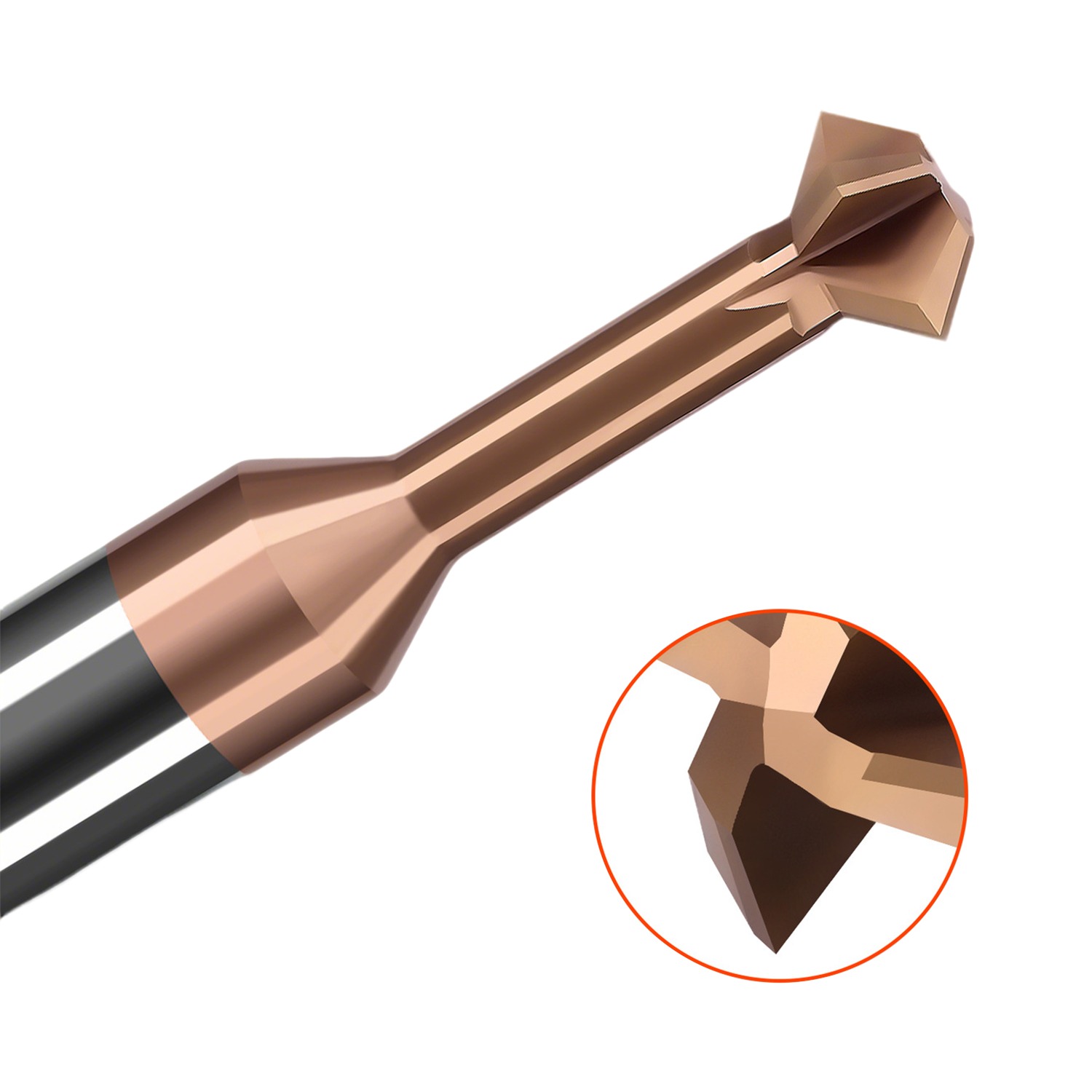

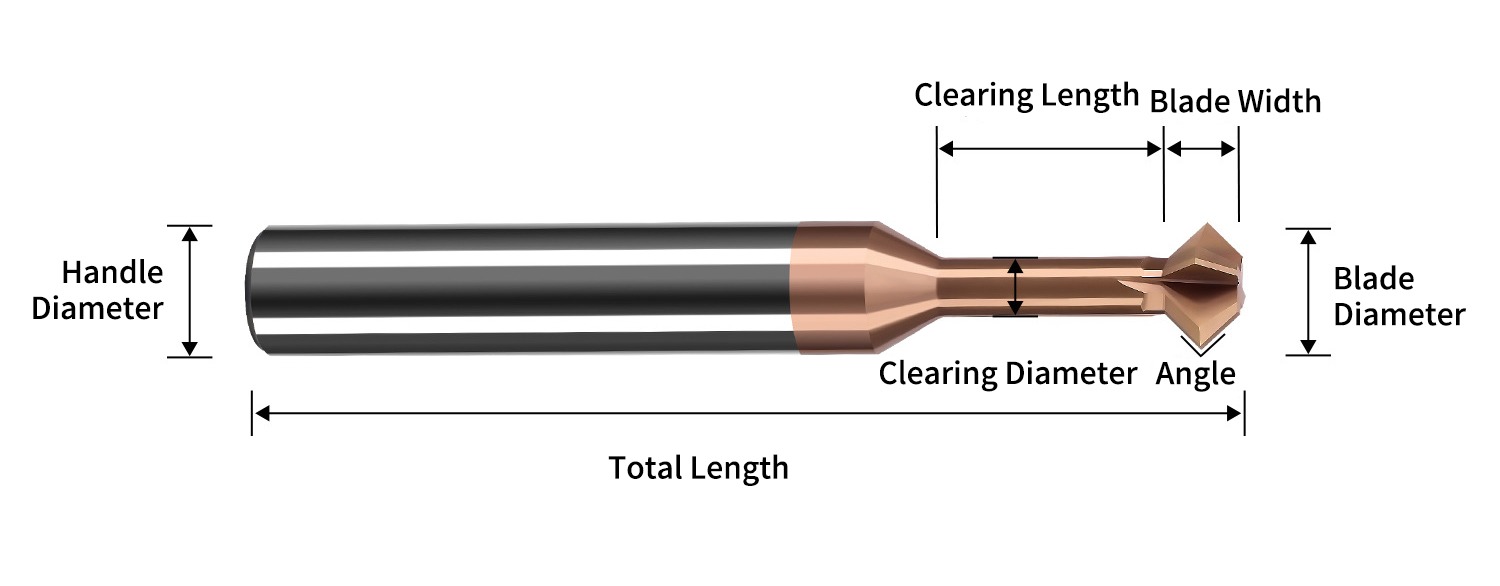

Designed specifically for efficient CNC milling and turning, this tungsten steel end mill features a four-edge structure and TiSiN coating, ensuring precise 90° chamfers and smooth deburring on steel, aluminum, and alloy materials. Its widened chip-removal grooves and blunted cutting edge provide excellent chip removal capability and durability, enabling stable completion of both front and back chamfers even for complex deep-hole workpieces, significantly enhancing production efficiency and processing quality.

Important Attributes

| Product Name | 90-degree chamfering tool | Brand | Moscow Oblast |

| Coating | TiSiN coating | Number of cutting edges | Four cutting edges |

| Applicable materials | Common steel, stainless steel, castiron, carbon steel, etc. |

Applicable equipment | CNC machining centers, engraving machines, precision engraving machines, etc. - high-speed machine tools |

| Coating | Composite Nanomaterial | HRC | 55HRC |

| Material | Hard Alloy | Support customization | OEM |

| Applicable machine | Vertical milling machine, horizontal milling machine |

Cutting direction | Conventional milling |

| Length of the cutting edge | / | Place of Origin | Tianjin, China |

| Model number | MSKDT | brand | MSK |

| Cutting hardness | hrc55, hrc45 | Effective cutting length | / |

| Trough shape | 4 flutes | helix angle | / |

| Warranty period | 3 months | Product Name | Beveling tool |

| Application | CNC milling | Packaging | 1ps / Plastic Box |

| Flute | 4 | Type | milling cutter |

| Suitable | Copper, cast iron, carbon steel, mold steel |

Minimum order quantity | Ten items |

| Advantages | Sharp cutting edge | Usage instructions | General high-speed cutting |

| Color | Metallic color | ||

Product Features

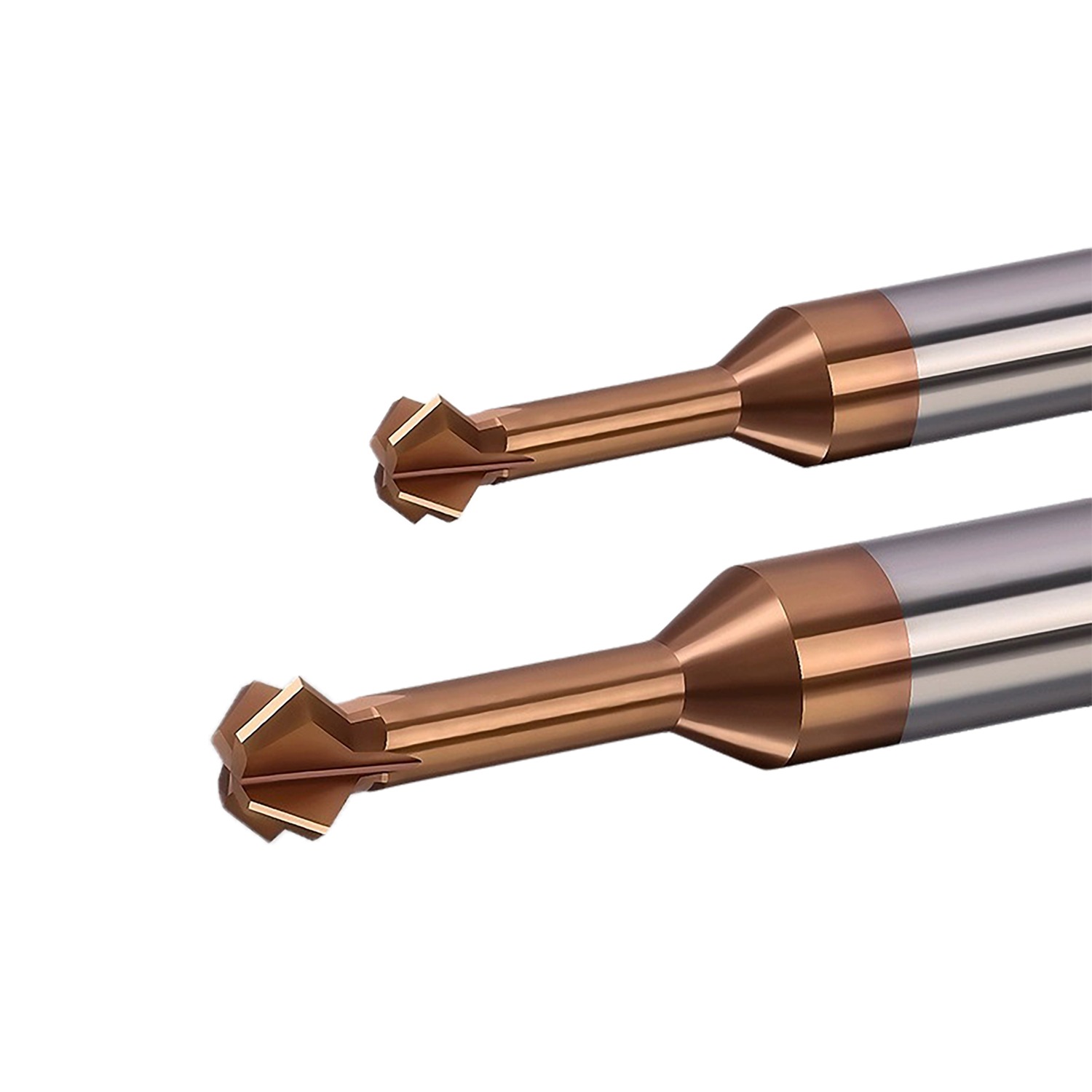

Tungsten steel milling cutter

Achieve a perfect 90° angle. Use our integral hard alloy face mill for chamfering and precise edge deburring. This tool features a sturdy four-edge design and a wear-resistant coating, ensuring exceptional durability and delivering excellent surface finish on steel, aluminum, and alloy materials. Perfect for efficient CNC milling and turning operations.

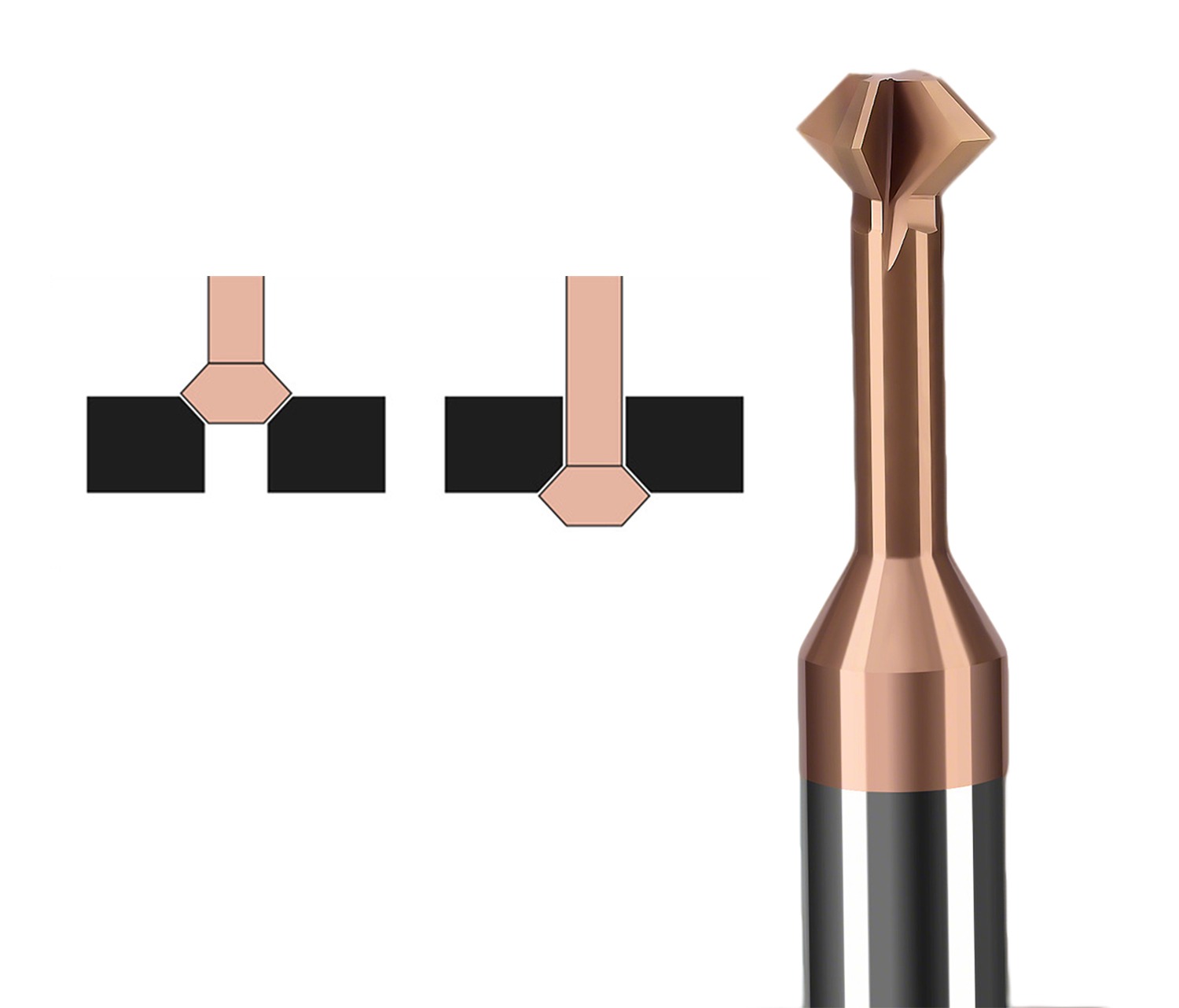

Positive and negative chamfers

For complex workpiece shapes, positive and negative chamfers can be applied, including chamfering for deep hole workpieces.

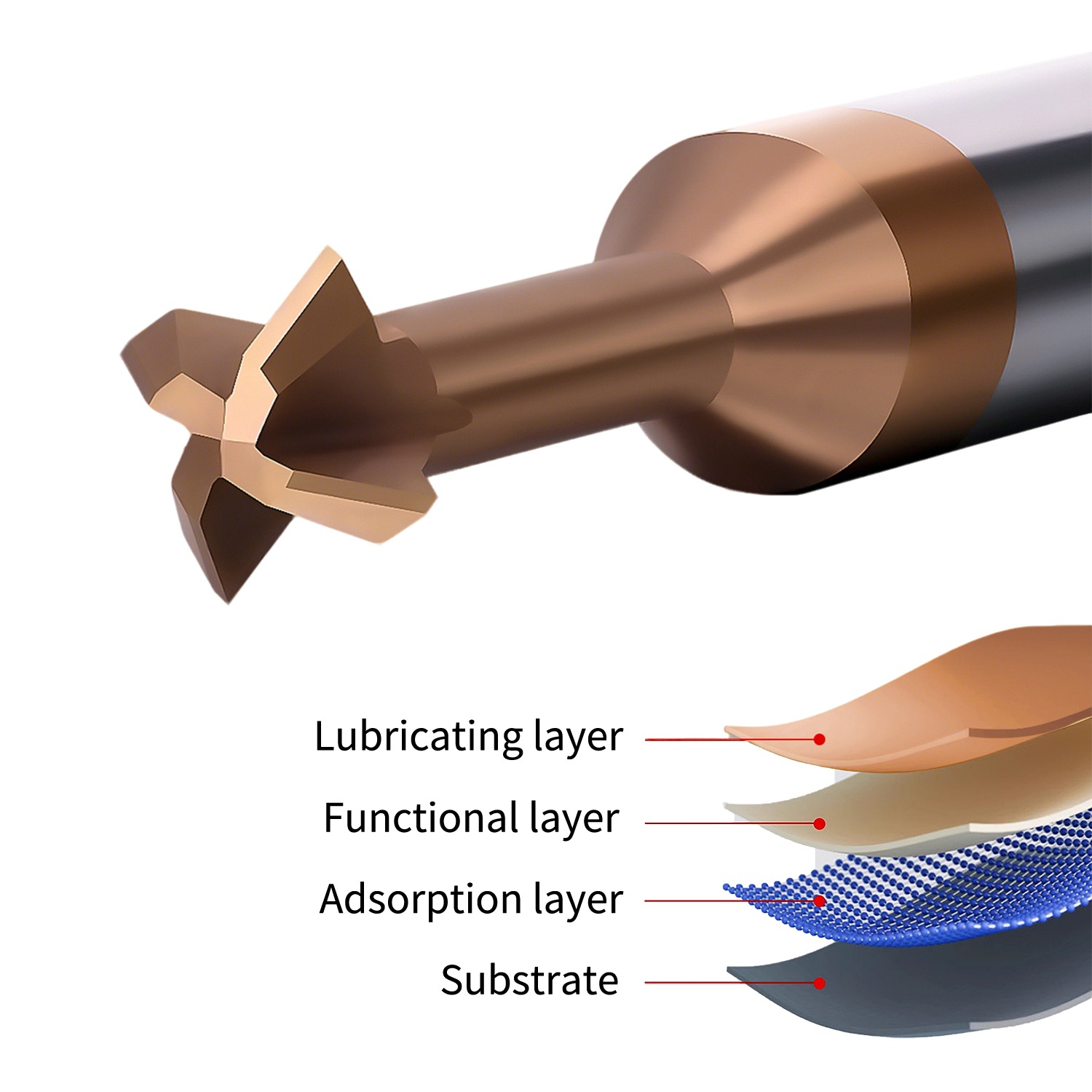

TiSiN coating

The upgraded coating enhances the wear resistance, ensuring that the cutting edge remains sharp and undamaged during rapid milling, and providing excellent durability.

High chip removal capacity

Full grinding spiral groove

Widened straight groove chip removal design, avoiding problems such as tool clogging and chipping, significantly improving production efficiency.

Unique tooth shape design

Smooth cutting, no chip accumulation, excellent stability, suitable for large-scale thread processing.

Passivation treatment

After the blade undergoes the passivation treatment process, when observed under the magnifying detection equipment, no minor defects are found. This enhances the durability of the cutting tool and the surface finish of the processed products.

Advantages

1.All-round processing, with outstanding precision

Achieve Perfect 90°: Optimized for precise chamfering and edge deburring, it enables effortless creation of high-quality right-angle contours.

Balancing both positive and negative chamfers: The unique edge design enables both front and back chamfering, significantly expanding the processing range. It is particularly suitable for complex-shaped workpieces and deep-hole chamfering, solving the processing challenges that traditional tools cannot reach.

2. Exceptionally durable, with a long lifespan

Sturdy four-edge design: Provides excellent tool rigidity and stability, disperses cutting forces, and reduces the load on a single cutting edge.

Upgrade TiSiN coating: Significantly enhances wear resistance and oxidation resistance. During high-speed milling, it can effectively maintain the sharpness of the cutting edge, prevent chipping and thermal wear, and significantly extend the service life of the cutting tool.

Edge hardening treatment: Through precise hardening process, microscopic defects (such as burrs and micro-fractures) are eliminated, making the edge surface smoother and more robust. This not only enhances the impact resistance and durability of the tool itself, but also directly results in better surface finish of the workpiece.

3. Chip removal is smooth, stable and efficient.

Wider straight slot chip removal design: Combined with the full grinding spiral groove, a spacious and smooth chip removal channel is formed. This can effectively prevent chip adhesion, accumulation and entanglement, fundamentally preventing the occurrence of tool chipping, overheating and processing quality degradation due to poor chip removal.

Unique tooth shape design: Optimized for processing of threads and complex contours, ensuring a smooth and stable cutting process, with reduced chip accumulation, and guaranteeing excellent stability in large-scale continuous processing.

4. Widely applicable and reliable performance

Multi-material compatibility: Optimized for performance, it can excel on steel, aluminum, and various alloy materials, achieving excellent surface processing quality.

Multi-process compatibility: Not only is it applicable to chamfering and deburring operations on CNC milling machines, but its stability also makes it suitable for efficient combined turning and milling processes as well as large-scale thread processing.

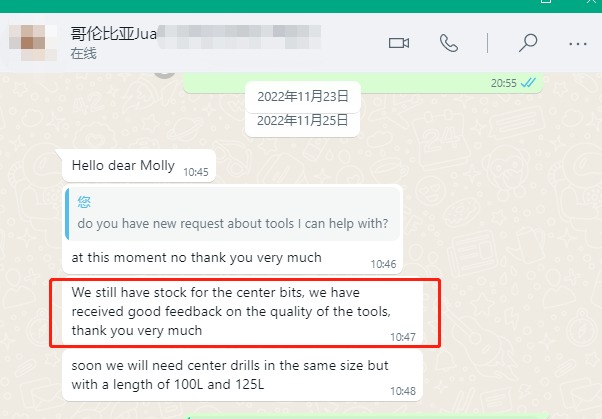

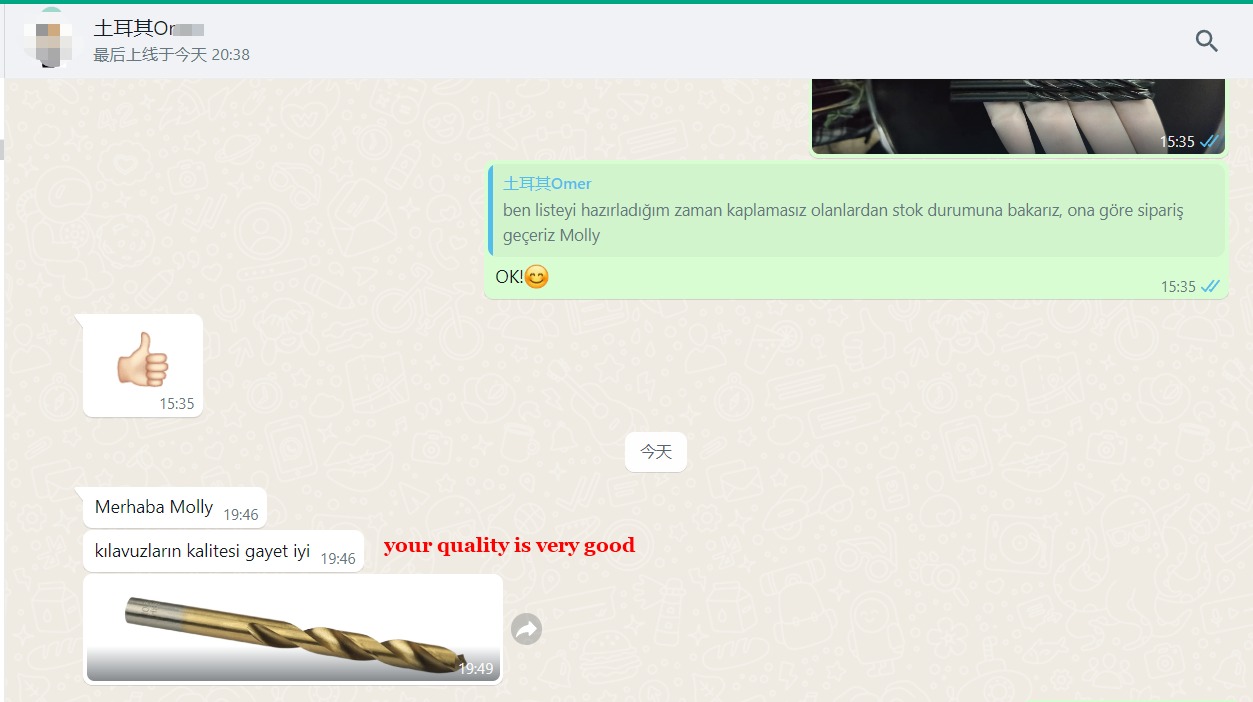

Why Choose Us

Factory Profile

FAQS

Q1.What are the advantages of the four-edge design of this tungsten steel end mill?

A:The four-edge design offers excellent rigidity and stability, making it particularly suitable for precise chamfering and edge deburring. Its sturdy structure can effectively resist cutting forces, ensuring excellent surface finish and dimensional accuracy on steel, aluminum, and alloy materials. It is especially suitable for efficient CNC milling and turning operations.

Q2.What does the "positive and negative chamfering" function of the cutting tool refer to?

A:The "positive and negative chamfering" function means that this milling cutter not only can perform the conventional outer edge or top surface chamfering, but also its unique blade design enables it to be suitable for performing inward or reverse chamfering on complex workpieces (such as the inner walls of deep holes or the backs of stepped structures), greatly expanding the application scope of the process and allowing multiple operations to be completed in one setup.

Q3.What performance improvements have been brought about by the upgrade of the TiSiN coating?

A:The upgraded TiSiN (nitrided titanium) coating boasts extremely high hardness and excellent heat resistance. It significantly enhances the wear resistance of the cutting tool, enabling it to maintain a sharp cutting edge for a long time even during rapid milling. It effectively prevents coating peeling and blade edge cracking, thereby providing outstanding tool durability and processing consistency.

Q4.How does the design of full grinding spiral grooves and widened straight grooves help improve processing efficiency?

A:The spiral grooves formed through the full grinding process have excellent surface finish and geometric accuracy. Combined with the widened straight groove design, it creates a larger chip-discharging space and a smoother chip-discharging path, enabling the rapid removal of chips. This fundamentally avoids problems such as tool sticking with chips, excessive temperature, built-up chips, and even tool breakage caused by poor chip discharge, thereby significantly enhancing processing efficiency and safety.

Q5.Why is the blade surface treated with passivation? What are the practical benefits of this process?

A:Passivation treatment is a precise micro-grinding process for the blade edge, aiming to remove microscopic defects such as visible micro-nicks and burrs under a microscope, so that the blade edge forms uniform and smooth small arcs. This can significantly reduce the initial wear and micro-fractures during the cutting process, directly improving the durability (life) of the tool, while reducing friction and vibration during processing, thereby achieving better surface finish of the workpiece.