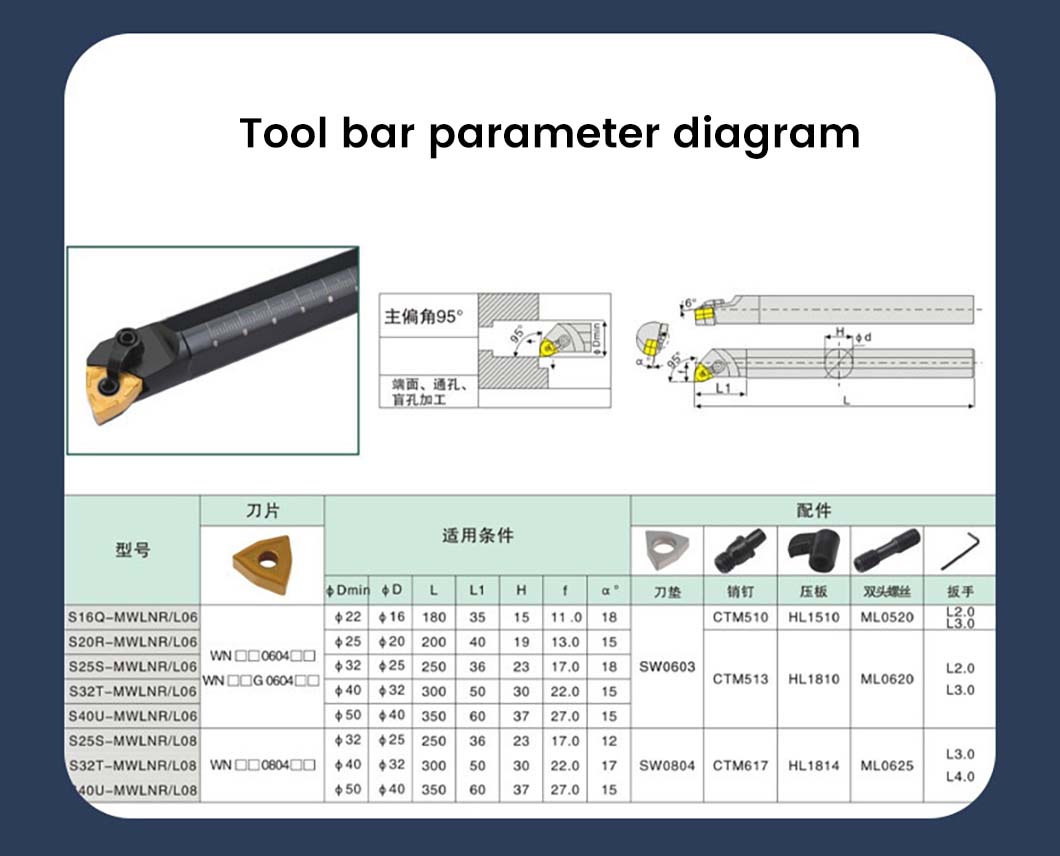

95° Anti-Vibration High Speed Steel Internal Toolholder For CNC Lathe Carbide Inserts

Double locking for a snug fit

Positive and negative knives are optional to meet different processing requirements.

1060° high temperature quenching and hardening treatment.

Specification

|

Product name

|

Composite inner hole tool bar

|

Brand:

|

MSK

|

|

Material

|

High speed steel

|

Accessories

|

Pressure plate/stud screw/pin/shim/wrench

|

Tool bar model For example:

Precautions for use

Matching blade, tight fit.

FAQs

1. Back damage: (this is a common effective form)

Impact: The workpiece size gradually changes or the surface finish decreases.

Reason: The line speed is too high and the tool life is reached.

Measures: Adjust processing parameters, such as reducing line speed and using blades with higher wear resistance.

2. Breaking problem: (bad effect form)

Impact: The workpiece size or surface finish changes suddenly, sparks and burrs are generated on the surface. Cause: Inappropriate parameter settings, inappropriate blade material selection, poor workpiece rigidity, unstable blade clamping. Measures: Check whether the parameter settings are reasonable, select the corresponding tool according to the workpiece material,

3. Severe fracture: (very bad effect form)

Impact: Sudden and unexpected occurrence, resulting in the scrapping of toolholder materials or defective and scrapped workpieces. Cause: Wrong machining parameter setting, vibrating workpiece or blade not installed in place. Measures: Set reasonable machining parameters, reduce feed rate and reduce chips, select corresponding machining blades to strengthen the rigidity of workpieces and blades.

4.Built-up edge

Impact: inconsistent workpiece size, poor surface finish, lint or burrs on the workpiece surface. Cause: too low cutting speed, too low feed, blade/not sharp enough. Measures: increase cutting speed, feed rate and use sharper blades.

Why Choose Us

Factory Profile

About Us

FAQ

Q1: who are we?

A1: Founded in 2015, MSK (Tianjin) Cutting Technology CO.Ltd has grown continuously and passed Rheinland ISO 9001

authentication.With German SACCKE high-end five-axis grinding centers, German ZOLLER six-axis tool inspection center, Taiwan PALMARY machine and other international advanced manufacturing equipment, we are committed to producing high-end,professional and efficient CNC tool.

Q2: Are you trading company or manufacturer?

A2: We are the factory of carbide tools.

Q3: Can you send products to our Forwarder in China?

A3: Yes,if you have Forwarder in China,we will glad to send products to him/her.Q4: What terms of payment are acceptable?

A4: Normally we accept T/T.

Q5: Do you accept OEM orders?

A5: Yes, OEM and customization are available, and we also provide label printing service.

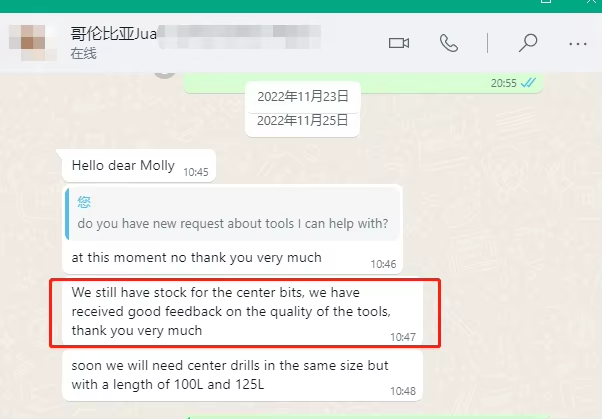

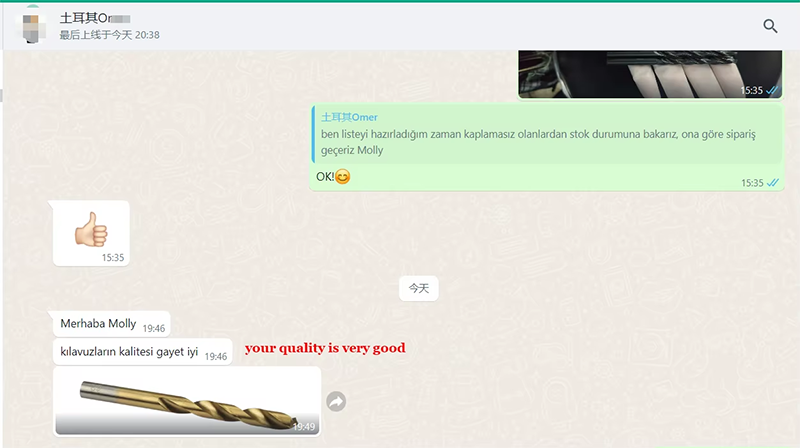

Q6: Why should you choose us?

A6:1) Cost control - purchasing high-quality products at an appropriate price.

2) Quick response - within 48 hours, professional personnel will provide you with a quote and address your concerns.

3) High quality - The company always proves with sincere intention that the products it provides are 100% high-quality.

4) After sales service and technical guidance - The company provides after-sales service and technical guidance according to customer requirements and needs.