Yakhelwe ngokucacile izinhlelo zokusebenza zokuguqula i-CNC ezidingayo, leziizinto zokufaka i-carbidesetha izinga elisha lokumelana nokuguguleka, ukulawula ama-chip, kanye nokukhiqiza kuma-workshop abhekana nezinsimbi eziqinile ezingagqwali.

Umshini wokugaya insimbi engagqwali unzima kakhulu. Ukuthambekela kwawo kokusebenza kanzima, ukukhiqiza ukushisa okukhulu, ukukhiqiza ama-chips aqinile, futhi kubangele ukuguguleka okukhulu kwamathuluzi kuye kwahlupha abakhiqizi isikhathi eside, okuholela ekushintsheni okuvamile kokufakwa, ukuqeda kobuso okonakalayo, kanye nokunciphisa umkhiqizo jikelele. Umshini omusha we-MSK ubhekana ngqo nalezi zindawo ezibuhlungu nge-trifecta eyinkimbinkimbi yokuklama kanye nesayensi yezinto ezibonakalayo.

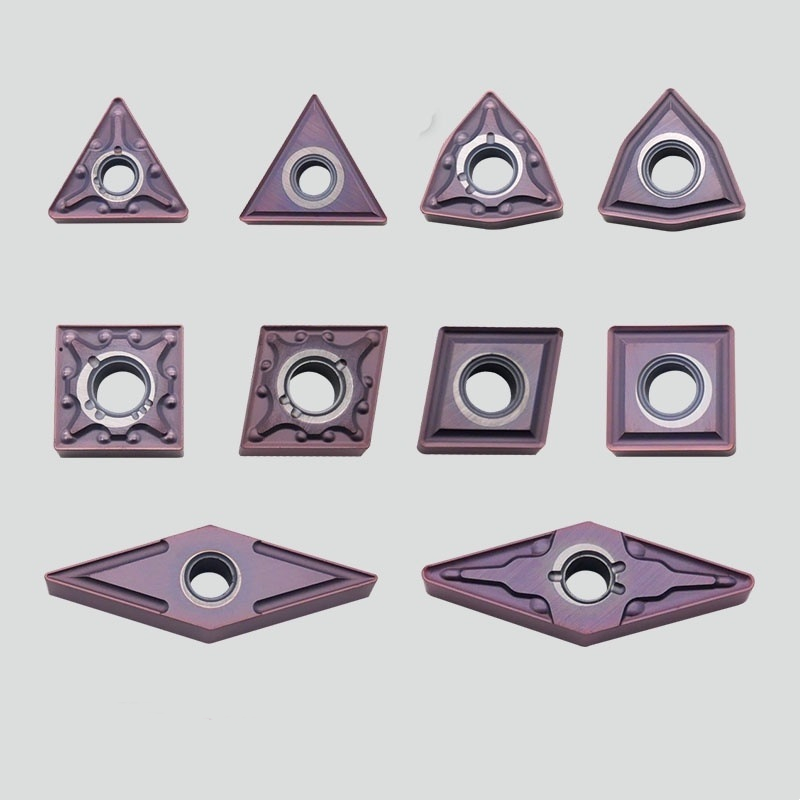

Yenzelwe Ukusebenza Okuphezulu Kwensimbi Engagqwali:

Umshini Osebenza Kakhulu: Enhliziyweni yalezi zifakelo kukhona i-substrate ye-carbide encane ethuthukisiwe eyenzelwe ukuqina okushisayo okungavamile kanye nokumelana nokuguquguquka ngaphansi kwezingcindezi ezinkulu kanye namazinga okushisa ahlangana nawo lapho kusikwa insimbi engagqwali. Kuhlanganiswe ne-geometry yobuso be-rake ebushelelezi kakhulu, elungiselelwe kahle kanye ne-angle enhle ye-rake, izifakelo zinciphisa kakhulu amandla okusika. Lokhu kuvumela izikhungo zokujika ze-CNC ukuthi zisebenze ngesivinini esikhulu sokusika kanye namazinga okuphakelayo kunangaphambili ngezifakelo ezivamile, okwandisa kakhulu amazinga okususa insimbi kanye nezikhathi zomjikelezo wokusikwa.

Imelana Nokugqokwa Futhi Iyasebenza: Isikhathi eside sibaluleke kakhulu. I-MSK isebenzisa isembozo sesimanje esinezingqimba eziningi ze-Physical Vapor Deposition (PVD), njenge-TiAlN (Aluminium Titanium Nitride) ehlukile ekhethekile. Lesi sembozo sinikeza isithiyo esiyingqayizivele ngokumelene nokugqokwa okukhuhlayo, ukugqokwa kwe-crater, kanye nokugqokwa kokusabalalisa okuvamile lapho kusetshenziswa ama-alloy aqinile angagqwali. Umphumela uba isikhathi eside kakhulu sokuphila kwamathuluzi, kunciphisa imvamisa yokufakwa kwe-indexing kanye nokushintsha kwamathuluzi. Lokhu kuholela ngqo ekwehliseni izindleko zamathuluzi ngengxenye ngayinye, ukunciphisa isikhathi sokungasebenzi komshini, kanye nokwanda kokubikezela phansi kwesitolo. I-substrate eqinile iphinde ithuthukise ukumelana nokuqhekeka kanye nokuqhekeka okuncane, ukuqinisekisa ukusebenza okuqhubekayo ngisho nangaphansi kokusikeka okuphazamisekile okuvamile ekusetshenzisweni kwe-stainless.

Ukuphuka Kwe-Chip Okubushelelezi: Ukwakheka kwe-chip okungalawulwa kuyingozi enkulu yokuphepha futhi kungalimaza kokubili i-workpiece kanye nethuluzi. Onjiniyela be-MSK baklame ngokucophelela i-geometry ye-chipbreaker esebenza kahle kakhulu ehlanganiswe endaweni ephezulu ye-insert. Le geometry iqondisa kahle i-chip, ibangela ukugoba okulawulwayo kanye nokuphuka kube yizingcezu ezibunjwe ngendlela "C" noma "6" noma "9" ezilawulekayo, eziphephile kuzo zonke izinhlobo zamapharamitha okusika (okuphakelayo, ukujula kokusikwa). Ukususwa kwe-chip okuhlala njalo, okubushelelezi kuvimbela ukuboshwa kwe-chip eduze kwethuluzi noma i-workpiece, kuvikela unqenqema lokusika ekusikeni kabusha ama-chip, kuthuthukisa ukuqeda kobuso, futhi kuthuthukisa ukuphepha komqhubi. Lokhu kulawulwa kwe-chip okuthembekile kubalulekile ekusebenzeni kokujika kwe-CNC okunganakiwe noma okukhanyisayo.

Kwenzelwe Ukukhiqiza Kokujika Kwe-CNC: Lezi zi-insert zenzelwe ukwandisa amakhono ezikhungo zesimanje zokujika ze-CNC. Ukusebenza kwazo okuqhubekayo kuvumela abahleli bezinhlelo ukuthi basunduze imishini ngokuzethemba kumapharamitha abo afanele, bazi ukuthi izi-insert zingabhekana nezidingo zensimbi engagqwali. Ukuhlanganiswa kwamandla asheshayo, impilo yamathuluzi ende, kanye nokuphuka kwama-chip okuthembekile kunciphisa isikhathi sokungasiki futhi kuqinisekisa ukusebenza kahle kokukhiqiza.

Izicelo Eziqondiwe: Lezi zifakelo ezikhethekile zilungele ukucubungula izinhlobo eziningi ze-austenitic (isb., 304, 316), i-duplex, kanye ne-super duplex stainless steels kuzo zonke izimboni ezibalulekile okuhlanganisa:

Uwoyela negesi (Amavalvu, Izinto Zokufaka)

Izindiza (Izingxenye ze-Hydraulic)

Ukukhiqizwa Kwamadivayisi Ezokwelapha (Izinto Ezifakwayo, Amathuluzi)

Imishini Yokucubungula Amakhemikhali

Imishini Yokudla Neziphuzo

Ubunjiniyela Obujwayelekile Bokucacisa

Mayelana ne-MSK

I-MSK (Tianjin) International Trading CO.,Ltd yasungulwa ngo-2015, futhi inkampani iqhubekile nokukhula nokuthuthuka phakathi nalesi sikhathi. Le nkampani iphumelele isitifiketi se-Rheinland ISO 9001 ngo-2016. Inemishini yokukhiqiza ethuthukisiwe yamazwe ngamazwe njengesikhungo sokugaya esisezingeni eliphezulu sase-SACCKE, isikhungo sokuhlola amathuluzi ayisithupha sase-German ZOLLER, kanye nethuluzi lomshini lase-Taiwan PALMARY. Izimisele ukukhiqiza amathuluzi e-CNC asezingeni eliphezulu, angochwepheshe futhi asebenzayo.

Isikhathi sokuthunyelwe: Juni-23-2025