Ingxenye 1

Ezweni lokukhiqiza kanye nobunjiniyela bokunemba, isibambi samathuluzi okunweba sivele njengesixazululo esiyingqayizivele, saguqula inqubo yokubopha futhi sabeka amazinga amasha okusebenza. Enhliziyweni yomklamo waso kukhona isimiso sokwanda nokuncipha kokushisa, okusihlukanisa njengento eshintsha umdlalo embonini.

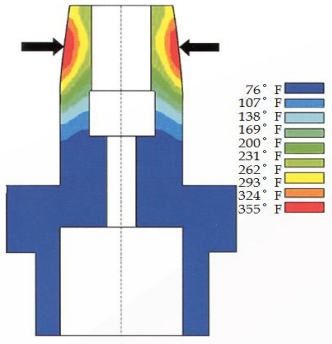

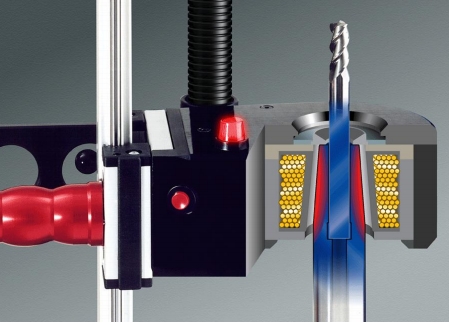

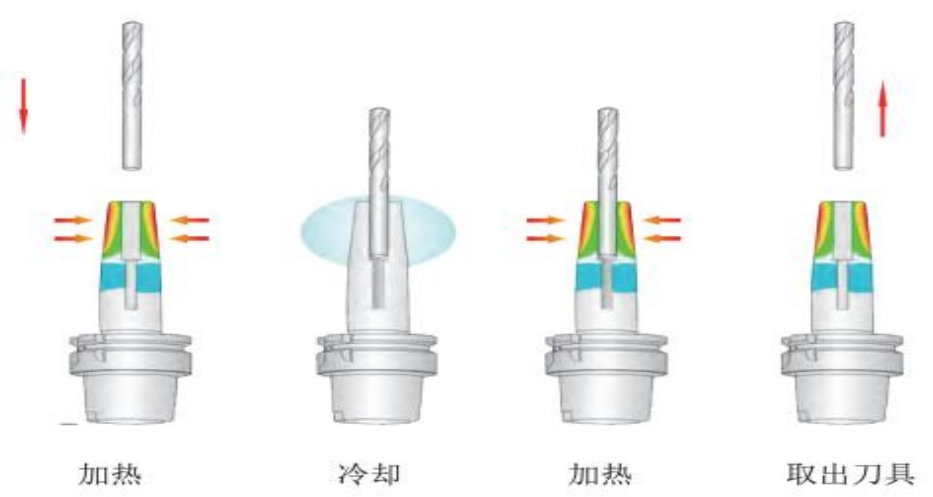

Umgomo Wokuqiniswa Kwesiphathi Sethuluzi Lokwandisa Isiphathi sethuluzi lokwandisa sisebenza ngesimiso esiyisisekelo sokwandiswa nokuncipha kokushisa, sisebenzisa amandla okushisa ukuze kufezwe ukuqina okulungile. Ngokusebenzisa idivayisi yokungenisa ukushisa, ingxenye yokuqinisa yaleli thuluzi ifudumala ngokushesha, okubangela ukwanda kobubanzi bangaphakathi besiphathi sethuluzi. Ngemva kwalokho, ithuluzi lifakwa ngaphandle kokuphazamiseka esiphathini sethuluzi esinwetshiwe, futhi lapho sipholile, isiphathi sethuluzi siyafinyela, sisebenzisa amandla afanayo okuqinisa ngaphandle kwezingxenye zokuqinisa zemishini.

Ingxenye 2

Izici Zesiphathi Sethuluzi Lokukhulisa Lesi sixazululo esisha sokubambelela sinezici eziningi ezihlaba umxhwele ezisihlukanisa nezindlela zendabuko:

Ukuphambuka okuncane kwamathuluzi (≤3μm) kanye namandla aqinile okubamba ngenxa yokubamba okufanayo

Idizayini encane futhi elinganayo enobukhulu obuncane bangaphandle, okwenza kube kuhle kakhulu ekusetshenzisweni kwemigodi ejulile

Ukuzivumelanisa nezimo okuguquguqukayo ekusebenzeni ngemishini esheshayo, okunikeza izinzuzo ezibalulekile kokubili ezinqubweni zokwenziwa kwemishini ezinzima neziphelele

Isivinini sokusika esithuthukisiwe, izinga lokuphakelayo, kanye nokuphela kobuso, ekugcineni kwandise isikhathi sokuphila sethuluzi kanye ne-spindle

Amathuluzi e-carbide aqinile ahlanganiswe nesiphathi samathuluzi okwandisa angabona ukwanda okuphawulekayo kokuphila kwamathuluzi ngaphezu kuka-30%, kanye nokuthuthukiswa kokusebenza kahle okungu-30%, okuqinisa isimo sawo njengesiphathi samathuluzi okubopha esinokunemba okuphezulu futhi esiqinile.

Ukusetshenziswa Kwesiphathi Sethuluzi Lokukhulisa Ukuze kwandiswe amandla esiphathi sethuluzi lokukhulisa, kunconywa ukuthi sisetshenziswe ekubambeni amathuluzi anezinduku ezisilinda. Amathuluzi anobubanzi obungaphansi kuka-6mm kufanele anamathele ekubekezeleni kwe-shank okungu-h5, kuyilapho lawo anobubanzi obungu-6mm noma ngaphezulu kufanele alandele ukubekezeleka kwe-shank okungu-h6. Nakuba isiphathi sethuluzi lokukhulisa sihambisana nezinto ezahlukahlukene zamathuluzi njengensimbi esheshayo, i-carbide eqinile, kanye nensimbi esindayo, i-carbide eqinile iyindlela ekhethwayo yokusebenza kahle.

Ingxenye 3

Izindlela Zokusebenzisa Namanothi Okuphepha Esibambi Sethuluzi Lokukhulisa Njenganoma yiliphi ithuluzi elithuthukile, ukuqonda ukusetshenziswa okufanele nokulandela izinqubo zokuphepha kubaluleke kakhulu. Ngesikhathi sokufakwa noma ukususwa kwamathuluzi, kubalulekile ukuqaphela ukuthi isibambi sethuluzi lokukhulisa singakhiqiza amazinga okushisa angaphezu kwama-degrees angu-300, isikhathi sokushisa esijwayelekile sisukela kumasekhondi angu-5 kuya kwangu-10. Ukuze kuphephe, kubalulekile ukugwema ukuthintana nezingxenye ezishisayo zesibambi sethuluzi ngesikhathi senqubo yokubamba futhi ugqoke amagilavu e-asbestos ngenkathi uphatha isibambi sethuluzi, ukunciphisa noma iyiphi ingozi yokusha.

Ukuzinza Nokuqina Ithuluzi lokukhulisa aligcini nje ngokuba uphawu lokusungula izinto ezintsha nokusebenza kahle kodwa futhi libonisa ubude besikhathi kanye nokuthembeka. Njengoba isikhathi senkonzo singaphezu kweminyaka emi-3, limelela ukwakhiwa kwalo okuhlala isikhathi eside kanye nomthelela oqhubekayo emisebenzini yokukhiqiza.

Ekuphetheni, isibambi samathuluzi okwandisa simelela intuthuko eqhubekayo kubuchwepheshe bokubopha, sinikeza ukunemba okungenakuqhathaniswa, ukusebenza kahle, kanye nokuthembeka. Ngomthelela waso oguqulayo endaweni yokukhiqiza, siqinise isimo saso njengethuluzi elibalulekile lobunjiniyela besimanje bokunemba.

Isikhathi sokuthunyelwe: Feb-28-2024