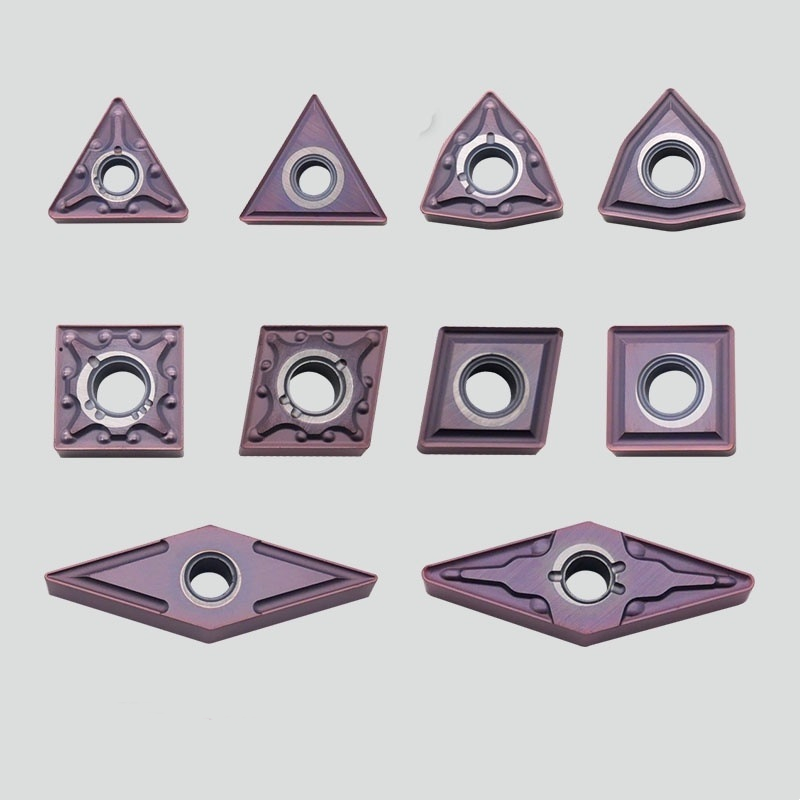

Yenzelwe ngokucacileyo izicelo zokujika ze-CNC ezifuna amandla, eziizinto zokuguqula ikhabhayithimisela umlinganiselo omtsha wokumelana nokuguguleka, ulawulo lweetshiphusi, kunye nemveliso kwiiworkshops ezijongene nee-alloys ezingenasici ezintsonkothileyo.

Umatshini wokulungisa intsimbi engagqwaliyo unzima kakhulu. Ukuthambekela kwawo ekusebenzeni nzima, ukuvelisa ubushushu obukhulu, ukuvelisa iitships eziqinileyo, kunye nokubangela ukuguguleka okukhulu kwezixhobo kuye kwabangela abavelisi ixesha elide, okukhokelela ekutshintsheni rhoqo kokufakwa, ukugqitywa komphezulu obuthathaka, kunye nokunciphisa imveliso iyonke. Ii-inserts ezintsha ze-MSK zijongana ngqo nale micimbi yentlungu nge-trifecta enobuchule yoyilo kunye nesayensi yezinto eziphathekayo.

Yenzelwe ukusebenza kakuhle kakhulu kwi-Stainless Steel:

Umatshini Osebenza Kakhulu: Embindini wezi zinto zokufaka kukho isiseko se-carbide esiphucukileyo esenziwe ngobuchule obuphezulu bokuqineka okushushu kunye nokuxhathisa ukuguquguquka phantsi koxinzelelo oluphezulu kunye namaqondo obushushu adibana nawo xa kusikwa intsimbi engatyiwayo. Xa idityaniswe ne-geometry yobuso be-rake egudileyo kakhulu, elungisiweyo kunye ne-angle ye-rake entle, ezi zinto zokufaka zinciphisa kakhulu amandla okusika. Oku kuvumela amaziko okujika e-CNC ukuba asebenze ngesantya esiphezulu sokusika kunye namazinga okutya kunokuba kunokwenzeka ngaphambili ngee-inserts zesiqhelo, okunyusa kakhulu amazinga okususa isinyithi kunye namaxesha okujikeleza kokusikwa.

Ayigugi kwaye iyasebenza: Ixesha elide libaluleke kakhulu. I-MSK isebenzisa uphahla olunemigangatho emininzi olune-Physical Vapor Deposition (PVD) olusemgangathweni, olufana nohlobo olukhethekileyo lwe-TiAlN (Aluminium Titanium Nitride). Olu phahla lubonelela ngomqobo okhethekileyo ngokuchasene nokuguguleka okurhabaxa, ukuguguleka kwe-crater, kunye nokuguguleka okuxhaphakileyo xa kusetyenzwa ii-alloys ezinamathelayo ezingenasici. Isiphumo sobude bexesha lesixhobo, kunciphisa ukuphindaphindeka kokufakwa kwe-indexing kunye notshintsho lwesixhobo. Oku kuthetha ngokuthe ngqo ekunciphiseni iindleko zesixhobo ngenxalenye nganye, ukunciphisa ixesha lokungasebenzi komatshini, kunye nokwanda kokuqikelelwa komgangatho wevenkile. I-substrate eqinileyo ikwaphucula ukumelana nokuqhekeka kunye nokuqhekeka okuncinci, ukuqinisekisa ukusebenza rhoqo nangona kunqunyulwe okuxhaphakileyo okuxhaphakileyo kwizicelo ezingenasici.

Ukuqhekeka kweChip okuSmooth: Ukwakheka kwechip okungalawulwayo kuyingozi enkulu yokhuseleko kwaye kungonakalisa zombini i-workpiece kunye nesixhobo. Iinjineli ze-MSK ziyile ngobuchule i-chipbreaker geometry esebenza kakuhle edityaniswe kumphezulu we-insert. Le geometry ikhokela ngokuchanekileyo i-chip, ibangela ukugoba okulawulwayo kunye nokuqhekeka kube ziziqwenga ezimile okwe-"C" okanye "6" okanye "9" ezilawulekayo, ezikhuselekileyo kuluhlu olubanzi lweeparamitha zokusika (i-feeds, ubunzulu bokusika). Ukukhutshwa kwe-chip okuhlala kuthambileyo, okugudileyo kuthintela ukuxinana kwe-chip ejikeleze isixhobo okanye i-workpiece, kukhusela umda wokusika kwii-chips eziphinda zisikwe, kuphucula ukugqitywa komphezulu, kwaye kuphucula ukhuseleko lomsebenzisi. Olu lawulo lwe-chip oluthembekileyo lubalulekile kwimisebenzi yokujika ye-CNC engajongwanga okanye ekhanyisayo.

Ilungiselelwe Imveliso Yokujika kweCNC: Ezi zifakelo zenzelwe ukwandisa amandla amaziko okujika eCNC anamhlanje. Ukusebenza kwazo rhoqo kuvumela abaqulunqi beenkqubo ukuba batyhale oomatshini ngokuzithemba kwiiparameter zabo ezifanelekileyo, besazi ukuba izifakelo zinokuhlangabezana neemfuno zentsimbi engagqwaliyo. Ukudibanisa amandla esantya esiphezulu, ubomi besixhobo obude, kunye nokuqhekeka kweetshiphusi okuthembekileyo kunciphisa ixesha lokunganqumi kwaye kuqinisekisa ukusebenza kakuhle kwemveliso.

Izicelo Ezijoliswe Kuzo: Ezi zinto zikhethekileyo zilungele ukwenziwa kwezixhobo ezahlukeneyo ze-austenitic (umz., 304, 316), ii-duplex, kunye neentsimbi ezingenasici ze-super duplex kumashishini abalulekileyo aquka:

Ioyile kunye neGesi (Iivalufu, Izinto zokufaka)

I-Aerospace (Iinxalenye zeHydraulic)

Ukwenziwa kweZixhobo zezonyango (Izifakelo, Izixhobo)

Izixhobo Zokucubungula Iikhemikhali

Oomatshini bokutya neziselo

Ubunjineli bokuGqibela ngokuBalaseleyo

Malunga ne-MSK

I-MSK (Tianjin) International Trading CO.,Ltd yasungulwa ngo-2015, kwaye inkampani iqhubekile nokukhula nokukhula ngeli xesha. Le nkampani iphumelele isiqinisekiso se-Rheinland ISO 9001 ngo-2016. Inezixhobo zokuvelisa eziphambili zamazwe ngamazwe ezifana neziko lokugaya elikumgangatho ophezulu le-SACCKE laseJamani, iziko lokuvavanya izixhobo ezi-six-axis laseJamani, kunye nesixhobo somatshini saseTaiwan PALMARY. Izimisele ukuvelisa izixhobo ze-CNC ezikumgangatho ophezulu, zobungcali nezisebenzayo.

Ixesha lokuthumela: Juni-23-2025