Iimpompo zekona ezijikelezayozikwaziwa ngokuba zii-tip taps kunye nee-edge taps kwishishini loomatshini. Eyona nto ibalulekileyo kwisakhiwo se-itephu yesikhonkwanengumngxuma okwisikrufu othe nkqo nofana nothambileyo okwisiphelo esingaphambili, ogoba ukusika ngexesha lokusika uze uwukhuphele ngaphambili kwimpompo nakwimbindi womngxuma wesikrufu.

Ngenxa yendlela yayo ekhethekileyo yokususa iitships,itephu yesikhonkwaneithintela ukuphazamiseka kwetshiphu kumphezulu wentambo owenziweyo, ukuze umgangatho womngxuma ogqityiweyo onentambo ube ngcono kunowomngxuma oqhelekileyo othe tye;

Ulwakhiwo lomngxuma ongaphantsi luqinisekisa ukupholisa kwaye luqinisa ukumelana ne-torque ekucutshungulweni kwempompo, ukuze ibe nesantya esiphezulu sokujikeleza kwaye ifaneleke ekucutshungulweni kwemisonto enzulu edlulayo;

Ngenxa yendlela yokususa iitshiphusi zetephu yesikrufu, kuyacetyiswa ukuba kusetyenziswe umatshini othe nkqo kunye nokufaka imingxunya edlulayo;

Ngokubanzi, xa kuthelekiswa neempompo zeflute ezijikelezayo, ubomi beempompo ze-spiral point bunokwandiswa ubuncinane ngesihlandlo esinye.

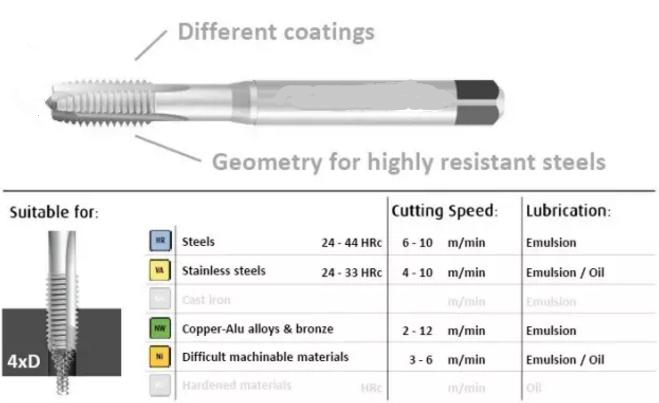

Ubulukhuni bomatshini: ≤32HRC; Isantya esicetyiswayo: malunga ne-8 ~ 12m/min; Indawo yokupholisa: ioyile okanye ioyile, ukupholisa i-emulsion;

*Isantya sokwenziwa kweempompo ezigqunywe ngumphezulu sinyuswa ngokuhambelanayo ngama-30%

Iiparameter zokusika iimpompo kunye nemilo yomngxuma Emva kovavanyo oluninzi lokusika, simisele iiparameter zempompo yesikhonkwane sokusebenza kwintsimbi engatyiwayo, intsimbi yekhabhoni ephantsi, ephakathi nephezulu, i-aluminium alloy, i-copper alloy, njl. I-tep isebenzisa inkqubo yokusila epheleleyo, kwaye umngxuma ucutshungulwa ngexesha elinye. Iintambo zicutshungulwa kwiimililo zemisonto ezingenisiweyo.

Ixesha lokuthumela: Juni-14-2022