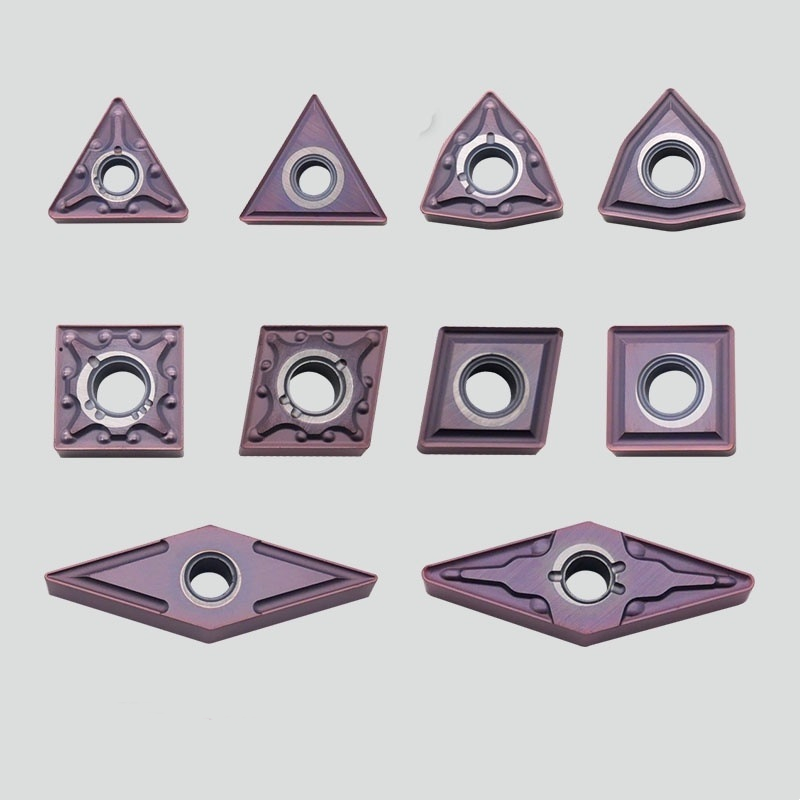

E etselitsoe ka ho hlaka bakeng sa lits'ebetso tse batlang ho fetola CNC, tsenali-insert tsa ho retelehela ka carbidebeha tekanyetso e ncha ea ho hanyetsa ho tsofala, taolo ea li-chip, le tlhahiso bakeng sa lithupelo tse sebetsanang le li-alloy tse sa hloekang tse phephetsang.

Ho sebetsa ka tšepe e sa ruseng ho tsebahala ka ho ba thata haholo. Tloaelo ea eona ea ho sebetsa ka thata, ho hlahisa mocheso o moholo, ho hlahisa li-chip tse thata, tse nang le likhoele, le ho baka ho senyeha ha lisebelisoa ho se ho ntse ho tšoenya bahlahisi ka nako e telele, e leng se lebisang liphetohong tse etsahalang khafetsa, ho fokotseng liphetho tsa bokaholimo, le ho fokotsa tlhahiso ka kakaretso. Li-insert tse ncha tsa MSK li sebetsana ka kotloloho le lintlha tsena tsa bohloko ka trifecta e rarahaneng ea moralo le saense ea thepa.

E entsoe bakeng sa Tshebetso e Phahameng ka Tšepe e sa Khaotseng:

Mechini e Sebetsang Haholo: Bohareng ba di-insert tsena ho na le substrate e tswetseng pele ya di-micro-grain carbide e entsweng bakeng sa ho thatafala ho chesang ho ikgethang le ho hanyetsa ho fetoha ha maemo tlasa dikgatello tse feteletseng le dithempereichara tse kopanang le tsona ha ho sehwa tshepe e sa ruseng. Ha e kopantswe le geometry ya sefahleho sa rake e boreledi haholo, e ntlafaditsweng le sekhutlo se setle sa rake, di-insert di fokotsa matla a ho seha haholo. Sena se dumella ditsi tsa ho reteleha tsa CNC ho sebetsa ka lebelo le hodimo la ho seha le sekgahla sa ho fepa ho feta kamoo ho neng ho ka kgoneha pele ka di-insert tse tlwaelehileng, e leng se eketsang sekgahla sa ho tlosa tshepe le dinako tsa potoloho ya ho seha.

E Hanela ho Tloha le ho Sebetsa: Nako e telele ke ea bohlokoa ka ho fetisisa. MSK e sebelisa seaparo sa sejoale-joale se nang le mekhahlelo e mengata sa Physical Vapor Deposition (PVD), joalo ka mofuta o khethehileng oa TiAlN (Aluminium Titanium Nitride). Seaparo sena se fana ka tšitiso e ikhethang khahlanong le ho tsofala ho hoholo, ho tsofala ha crater, le ho sotha ho tloaelehileng ha ho etsoa li-alloy tse khomarelang tse sa hloekang. Sephetho ke nako e telele haholo ea lisebelisoa, e fokotsang makhetlo a ho kenya indexing le liphetoho tsa lisebelisoa. Sena se fetolela ka kotloloho ho fokotsa litšenyehelo tsa lisebelisoa ka karolo, ho fokotsa nako ea ho se sebetse ha mochini, le keketseho ea ho bolela esale pele hore mokatong oa lebenkele o tla sebetsa hantle. Substrate e matla e boetse e eketsa khanyetso khahlanong le ho taboha le ho robeha ha li-micro-fractures, e netefatsa ts'ebetso e tsitsitseng esita le tlas'a ho robeha ho sitisoang ho tloaelehileng lits'ebetsong tse sa hloekang.

Ho Roba ha Chip e Boreledi: Ho thehoa ha chip e sa laoleheng ke kotsi e kholo ea polokeho 'me ho ka senya mosebetsi le sesebelisoa. Baenjiniere ba MSK ba entse ka hloko jiometri e sebetsang hantle ea chipbreaker e kopantsoeng holim'a karolo e ka holimo ea insert. jiometri ena e tataisa chip ka nepo, e etsa hore ho kobeha le ho robeha ho laoleheng ho be likaroloana tse bōpehileng joaloka "C" kapa "6" kapa "9" tse laolehang, tse bolokehileng ho pholletsa le mefuta e mengata ea liparamente tsa ho seha (lijo, botebo ba ho seha). Ho tlosoa ha chip e tsitsitseng le e boreleli ho thibela ho hohlana ha chip ho potoloha sesebelisoa kapa mosebetsi, ho sireletsa moeli oa ho seha ho li-chip tse sehang hape, ho ntlafatsa qetello ea bokaholimo, le ho ntlafatsa polokeho ea opereishene. Taolo ena e tšepahalang ea chip e bohlokoa bakeng sa ts'ebetso ea ho reteleha ha CNC e sa hlokomeloe kapa e timang.

E ntlafalitsoe bakeng sa Tlhahiso ea ho Fetola ha CNC: Li-insert tsena li etselitsoe ho eketsa bokhoni ba litsi tsa sejoale-joale tsa ho phetla tsa CNC. Tshebetso ea tsona e tsitsitseng e lumella baetsi ba mananeo ho sutumelletsa mechine ka kholiseho ho ea liparamenteng tsa bona tse ntle, ba tseba hore li-insert li ka sebetsana le litlhoko tsa tšepe e sa hloekang. Motsoako oa bokhoni ba lebelo le phahameng, bophelo bo bolelele ba lisebelisoa, le ho robeha ha chip ho tšepahalang ho fokotsa nako e sa seheng 'me ho netefatsa hore tlhahiso e sebetsa hantle le ka mokhoa o boreleli.

Ditshebediso tse reretsweng: Di-insert tsena tse ikgethang di loketse ho sebetsa ka mefuta e mengata ya di-austenitic (mohlala, 304, 316), di-duplex, le di-super duplex tse sa keneng ka hara diindasteri tsa bohlokwa ho kenyeletswa:

Oli le Khase (Li-valve, Lisebelisoa)

Lifofane (Likarolo tsa Hydraulic)

Tlhahiso ea Lisebelisoa tsa Bongaka (Li-implant, Lisebelisoa)

Lisebelisoa tsa ho Sireletsa Lik'hemik'hale

Mechini ea Lijo le Lino

Boenjiniere bo Akaretsang ba ho Sebetsa ka Botlalo

Mabapi le MSK

MSK (Tianjin) International Trading CO.,Ltd e thehiloe ka 2015, 'me khamphani e ntse e tsoela pele ho hola le ho ntlafala nakong ena. Khamphani e fetile setifikeiti sa Rheinland ISO 9001 ka 2016. E na le lisebelisoa tsa tlhahiso tse tsoetseng pele tsa machabeng tse kang setsi sa ho sila sa Jeremane sa SACCKE se nang le li-axis tse hlano tse phahameng, setsi sa tlhahlobo ea lisebelisoa tsa Jeremane sa li-axis tse tšeletseng, le sesebelisoa sa mochini sa Taiwan PALMARY. E ikemiselitse ho hlahisa lisebelisoa tsa CNC tsa maemo a holimo, tsa profeshenale le tse sebetsang hantle.

Nako ea poso: Phuptjane-23-2025