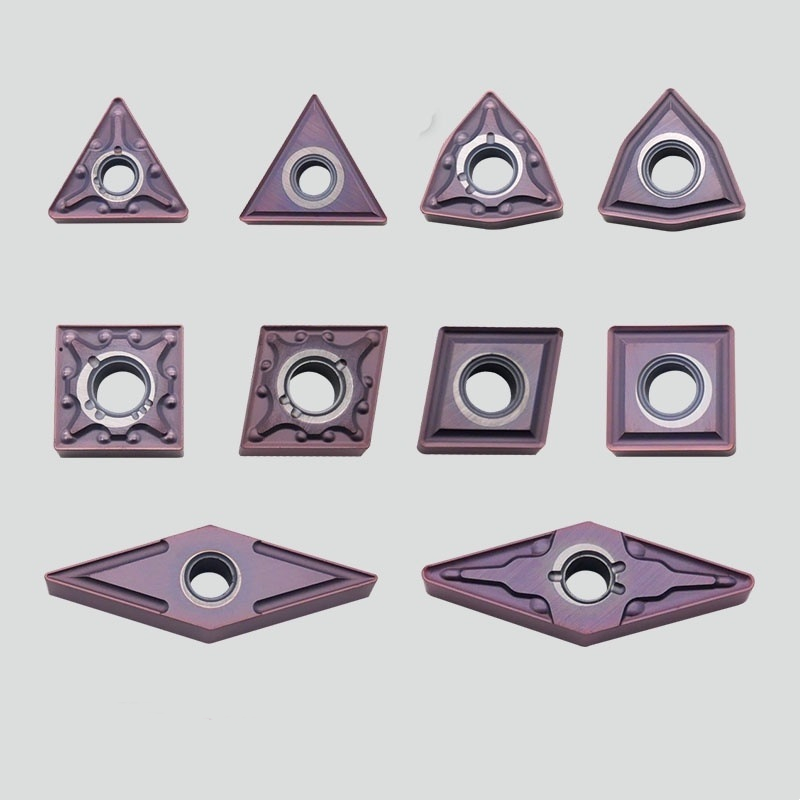

Yakagadzirirwa zvakananga kushandiswa kweCNC kushandura zvinhu, izvizvinhu zvinotenderedza kabhonigadza chiyero chitsva mukudzivirira kusakara, kudzora machipisi, uye kugona kushanda kwemaworkshops ekugadzirisa matambudziko esimbi dzisina ngura.

Kugadzira simbi isina ngura kwakaoma zvikuru. Katsika kayo kekushanda nesimba, kugadzira kupisa kwakanyanya, kugadzira machipisi akaomarara, uye kukonzera kusakara kwezvishandiso kwagara kuchinetsa vagadziri, zvichikonzera kuchinja-chinja kwekuisa, kukanganisa kugadzirwa kwechinhu, uye kudzikira kwekubudirira kwechinhu chose. Kugadzira simbi itsva dzeMSK kunobatsira zvakananga pakurwadziwa uku nekugadzira zvinhu zvitatu zvine hunyanzvi uye sainzi yezvinhu.

Yakagadzirwa kuti ishande zvakanaka muSimbi Isina Zvigadzirwa:

Kugadzira Machining Zvinoshanda Zvikuru: Pakati pezvinhu izvi pane substrate ye micro-grain carbide yakagadzirwa kuti ikwanise kupisa zvakanyanya uye kuramba kuchinjika pasi pekumanikidzwa kwakanyanya uye tembiricha dzinosangana nadzo pakucheka simbi isingatsvedzeri. Pamwe chete ne geometry yerake face yakapfava uye yakagadzirisika zvakanaka uye angle yakanaka yerake, zvinhu izvi zvinoderedza zvakanyanya simba rekucheka. Izvi zvinobvumira nzvimbo dzeCNC dzinotenderedza kuti dzishande nekukurumidza kwekucheka uye feed rates kupfuura zvaibvira kare nezvinoiswa zvemazuva ese, zvichiwedzera zvakanyanya mwero wekubvisa simbi uye nguva yekucheka.

Inodzivirira Kupfekwa Uye Inoshanda: Kugara kwenguva refu kwakakosha. MSK inoshandisa chifukidziro chemazuva ano cheMuviri weVapor (PVD) chakasiyana-siyana, senge TiAlN (Aluminum Titanium Nitride) yakasarudzika. Chifukidziro ichi chinopa chipingamupinyi chakakura kubva pakupfekwa, kupera kwecrater, uye kupararira kwemafuta anowanzo shandiswa pakugadzira alloys dzinonamira dzisina ngura. Mugumisiro wacho ndewekuti maturusi anogara kwenguva refu, zvichideredza kuwanda kwekuisa indexing uye shanduko dzematurusi. Izvi zvinoreva kudzikisa mitengo yekushandisa pachikamu chimwe nechimwe, kudzikisa nguva yekushanda kwemuchina, uye kuwedzera kugona kwekufungidzira pasi pechitoro. Chifukidziro chakasimba ichi chinowedzerawo kuramba kutsvedza uye kupwanyika, zvichiita kuti chishande zvakanaka kunyangwe paine kuchekwa kwakajairika mukushandiswa kwesimbi dzisina ngura.

Kupwanya Chip Zvakatsetseka: Kuumbwa kwechip chisina kudzorwa injodzi huru yekuchengetedza uye kunogona kukuvadza workpiece nemudziyo. Mainjiniya eMSK vakagadzira nehungwaru chimiro chechipbreaker chinoshanda zvikuru chakabatanidzwa pamusoro pechinhu chinoiswa. Geometry iyi inotungamira chip zvakanaka, zvichiita kuti kupeta nekupwanyika kudzorwa kuve zvidimbu zvakaumbwa "C" kana "6" kana "9" zvinogoneka, zvakachengeteka pamatanho akasiyana-siyana ekucheka (kudya, kudzika kwekucheka). Kubviswa kwechip kwakatsetseka, kwakasimba kunodzivirira kubatwa kwechip kwakatenderedza chishandiso kana workpiece, kunodzivirira mupendero wekucheka kubva pakuchekazve machip, kunovandudza kupedzwa kwenzvimbo, uye kunowedzera kuchengetedzeka kwemushandisi. Kudzora kwechip uku kwakavimbika kwakakosha kune mashandiro eCNC asina kutarisirwa kana kudzima magetsi.

Yakagadzirirwa Kubudirira kweCNC Turning: MaInsert aya akagadzirwa kuti awedzere kugona kwenzvimbo dzemazuva ano dzeCNC turning. Kushanda kwawo nguva dzose kunobvumira vagadziri vemapurogiramu kuti vasundire michina nechivimbo kumatanho avo akakodzera, vachiziva kuti maInsert acho anogona kubata zvinodiwa nesimbi isingatsvi. Kusanganiswa kwesimba rekumhanya, hupenyu hwematurusi hwakareba, uye kupwanyika kwemachipisi kwakavimbika kunoderedza nguva isingacheki uye kunoita kuti kugadzirwa kushande zvakanaka uye kunoshanda.

Mashandisirwo Azvo: Aya ma insert akakosha akanakira kugadzira simbi dzisina tsvina dzakasiyana-siyana (semuenzaniso, 304, 316), duplex, uye super duplex mumaindasitiri akakosha anosanganisira:

Oiri neGasi (Mavharuvhu, Zvishandiso)

Muchadenga (Zvikamu zveHydraulic)

Kugadzira Zvishandiso Zvekurapa (Zvigadzirwa, Zvishandiso)

Midziyo Yekugadzirisa Makemikari

Michina Yezvekudya Nezvinwiwa

Uinjiniya Hwakanaka Hwese

Nezve MSK

MSK (Tianjin) International Trading CO.,Ltd yakavambwa muna 2015, uye kambani iyi yakaramba ichikura uye ichibudirira munguva iyi. Kambani iyi yakapasa Rheinland ISO 9001 certification muna 2016. Ine michina yekugadzira yepamusoro-soro yepasi rose yakaita seGerman SACCKE high-end five-axis grinding center, German ZOLLER six-axis tool testing center, uye Taiwan PALMARY machine tool. Yakazvipira kugadzira maturusi eCNC emhando yepamusoro, ehunyanzvi uye anoshanda zvakanaka.

Nguva yekutumira: Chikumi-23-2025