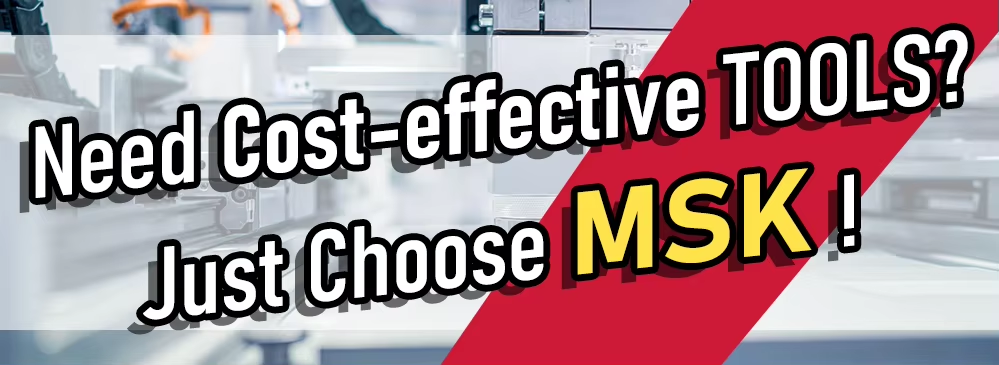

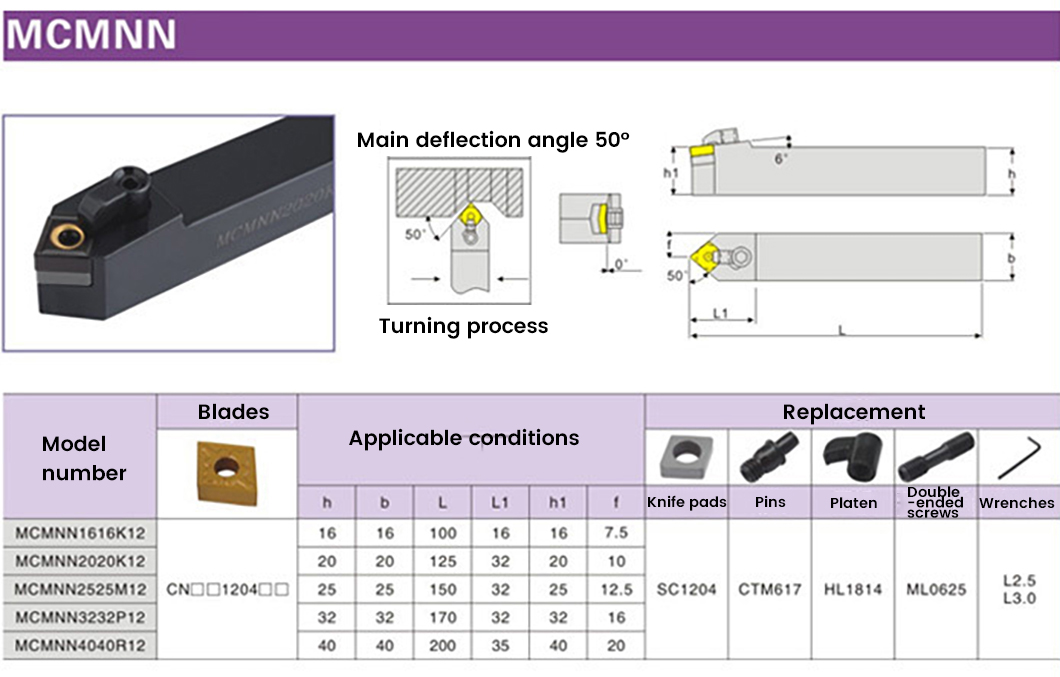

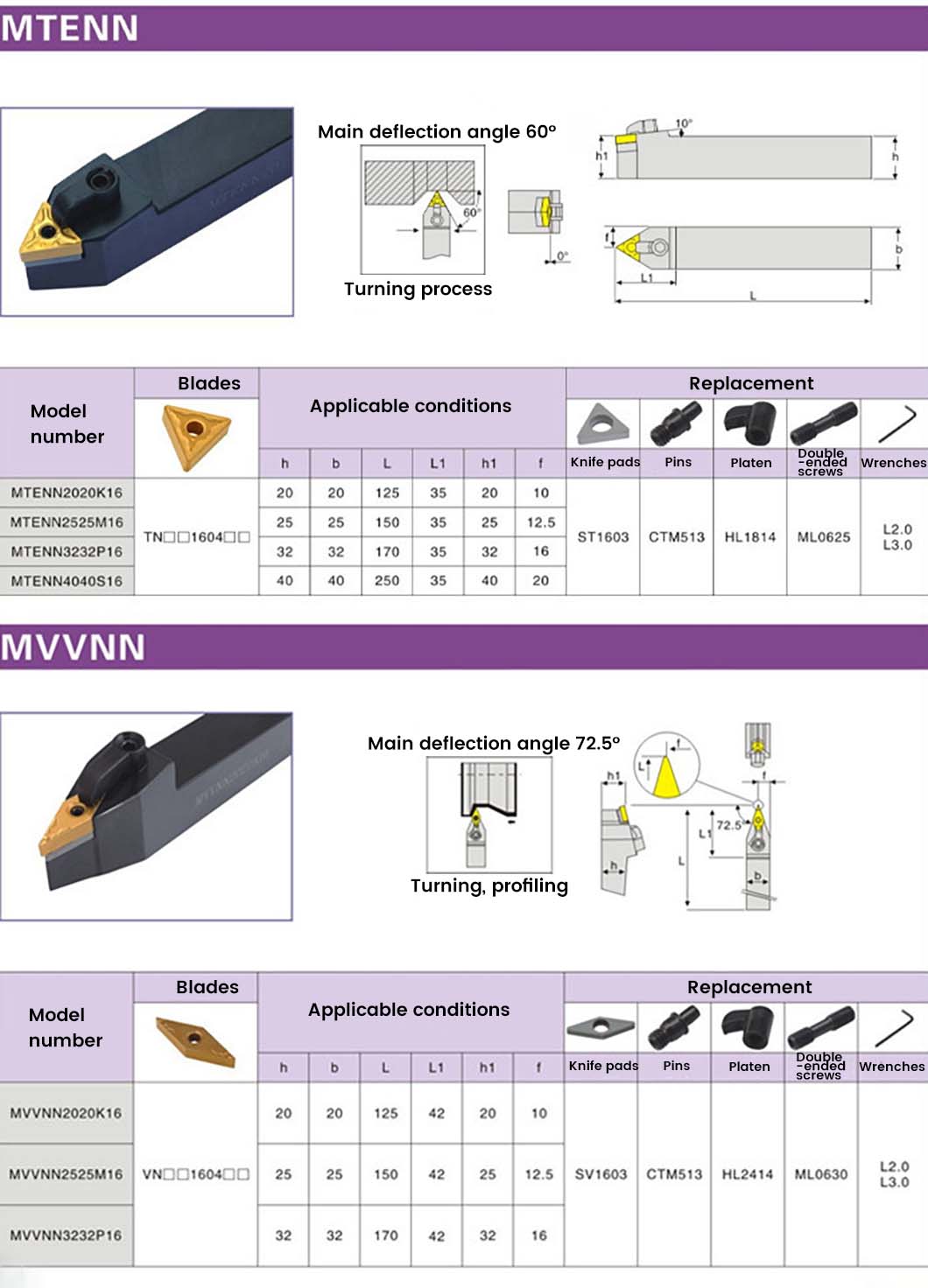

Precision CNC Lathe External Circle Tool Holder 16/20/25/32mm, Carbide Steel, Screw-Type

CNC Turning Tool Set Pressure Plate Intermediate Toolholder

Tight fit double lock

Precautions for use

Specification

Frequently Asked Questions

1. rear blade surface wear: (This is a common form of effectiveness)

Impact: gradual change in the size of the workpiece or surface finish degradation, cause: line speed is too high, to reach the tool life. Measures: adjust the processing parameters, such as reducing the line speed to use a higher wear resistance of the insert.

2. Chipping problem: (bad form of effectiveness)

Impact: sudden change in the size of the workpiece or surface finish, resulting in sparks surface burrs. Reason: parameter setting is not appropriate, blade material selection is not appropriate workpiece rigidity is not good, blade clamping instability. Measures: Check whether the parameter setting is reasonable, according to the workpiece material selection of the corresponding tool

3. Serious fracture: very bad form of effectiveness)

Impact: Suddenly and unpredictably occur, resulting in the shank material scrapped or workpiece bad and scrap. Reason: Processing parameters are set incorrectly, vibration knife workpiece or blade is not installed in place. Measures: Set reasonable processing parameters, should reduce the feed and reduce the chip selection corresponding to the processing blade to strengthen the rigidity of the workpiece and blade.

4. Accumulated chip tumor

Impact: inconsistent size of the workpiece, poor surface finish, the surface of the workpiece attached to the fluff or burrs.

Reason: cutting speed is too low, feed is too low blade / not sharp enough.

Measures: Increase the cutting speed and feed to use sharper inserts.

Why Choose Us

Factory Profile

About Us

FAQ

Q1: who are we?

A1: Founded in 2015, MSK (Tianjin) Cutting Technology CO.Ltd has grown continuously and passed Rheinland ISO 9001

authentication.With German SACCKE high-end five-axis grinding centers, German ZOLLER six-axis tool inspection center, Taiwan PALMARY machine and other international advanced manufacturing equipment, we are committed to producing high-end,professional and efficient CNC tool.

Q2: Are you trading company or manufacturer?

A2: We are the factory of carbide tools.

Q3: Can you send products to our Forwarder in China?

A3: Yes,if you have Forwarder in China,we will glad to send products to him/her.Q4: What terms of payment are acceptable?

A4: Normally we accept T/T.

Q5: Do you accept OEM orders?

A5: Yes, OEM and customization are available, and we also provide label printing service.

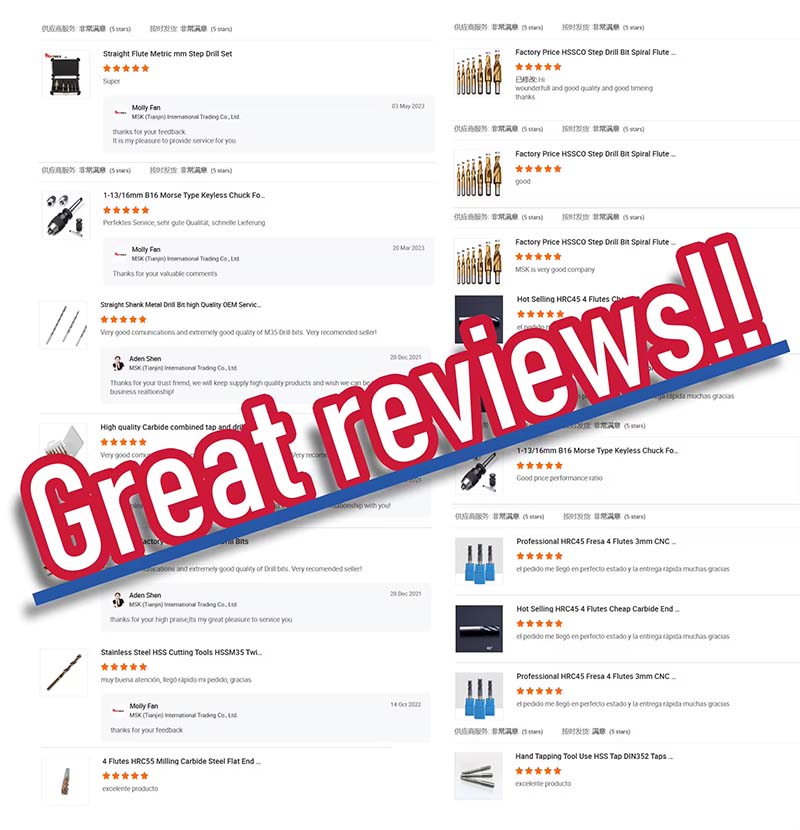

Q6: Why should you choose us?

A6:1) Cost control - purchasing high-quality products at an appropriate price.

2) Quick response - within 48 hours, professional personnel will provide you with a quote and address your concerns.

3) High quality - The company always proves with sincere intention that the products it provides are 100% high-quality.

4) After sales service and technical guidance - The company provides after-sales service and technical guidance according to customer requirements and needs.