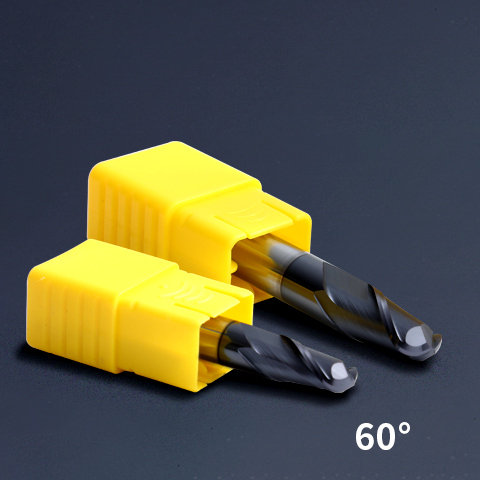

OEM/ODM Manufacturer 0.1 Mm End Mill - HRC60 CNC Tools carbide ball nose router bit – MSK

OEM/ODM Manufacturer 0.1 Mm End Mill - HRC60 CNC Tools carbide ball nose router bit – MSK Detail:

| Type | HRC60 CNC Tools carbide ball nose router bit | Material | Tungsten Steel |

| Workpiece Material | Copper, stainless steel, alloy steel, tool steel, quenched and tempered steel, carbon steel, cast iron, heat-treated hardened steel | Numerical Control | CNC |

| Transport Package | Box | Flute | 2 |

| Coating | AlTiSiN | Hardness | HRC60 |

Feature:

1.Use nano-tech, the hardness and thermal stability are up to 4000HV and 1200 degree, respectively.

2. Double-edge design improves rigidity and surface finish effectively. Cutting edge over the center reduces the cutting resistance. High capacity of junk slot benefits chip removal and increases machining efficiency. 2 flutes design is good for chip removal, easy for vertical feed processing, widely used in slot and hole processing.

Instructions for use

In order to get a better cutting surface and prolong tool life. Be sure to use high-precision, high-rigidity, and relatively balanced tool holders.

1. Before using this tool, please measure the tool deflection. When the tool deflection accuracy exceeds 0.01mm, please correct it before cutting

2. The shorter the length of the tool protruding from the chuck, the better. If the tool protruding is longer, please reduce the combat speed, feed speed or cutting amount by yourself

3. If abnormal vibration or noise occurs during cutting, please reduce the spindle speed and cutting amount until the situation is changed.

4. The steel material is cooled by spray or air jet as the applicable method to make the high aluminum titanium exert a good effect. It is recommended to use water-insoluble cutting fluid for stainless steel, titanium alloy or heat-resistant alloy.

5. The cutting method is affected by the workpiece, machine, and software. The above data is for reference. After the cutting condition is stable, increase the feed rate by 30%-50%.

Use:

Widely used in many fields

Aviation Manufacturing

Machine Production

Car manufacturer

Mold making

Electrical Manufacturing

Lathe processing

Product detail pictures:

Related Product Guide:

Our purpose is to fulfill our clients by offering golden company, great price and premium quality for OEM/ODM Manufacturer 0.1 Mm End Mill - HRC60 CNC Tools carbide ball nose router bit – MSK , The product will supply to all over the world, such as: Colombia, Slovak Republic, South Africa, Our company sticks to the principle of "high quality, reasonable price and timely delivery". We sincerely hope to establish good cooperative relationships with our new and old business partners from all parts of the world. We hope to work with you and serve you with our excellent goods and services. Welcome to join us!

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!