A collet is a locking device that holds a tool or workpiece and is usually used on drilling and milling machines and machining centers.

The collet material currently used in the industrial market is: 65Mn.

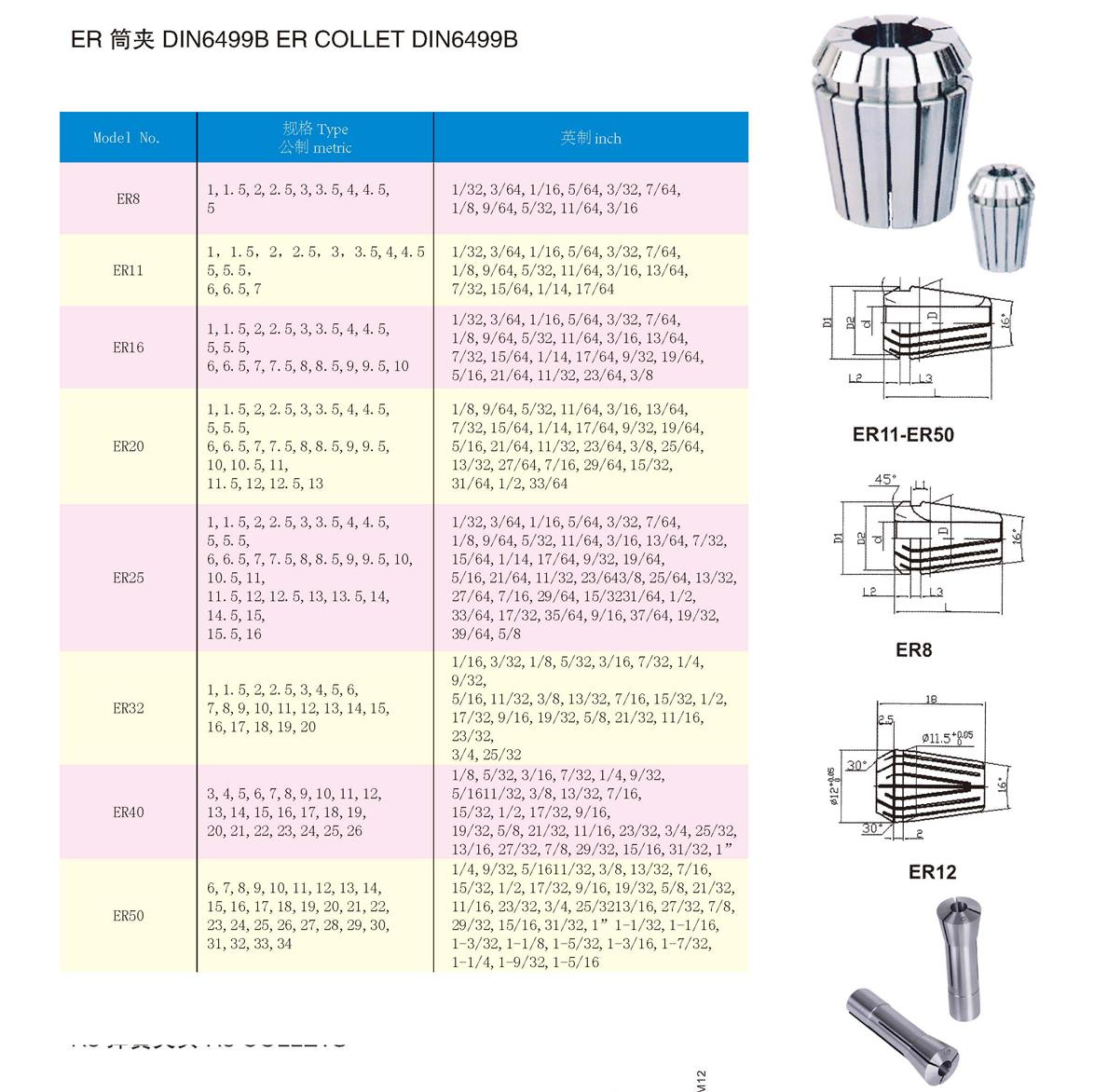

ER collet is a kind of collet, which has large tightening force, wide clamping range and good precision. It is generally used for supporting CNC tool holders and plays an important role in machine tools. The design and use of ER collets is a wide-ranging field. It needs to correspond to a variety of machine tool series, and includes products designed to reflect its different styles and features from machine tools. It is widely used. Boring, milling, drilling, tapping, grinding and engraving.

1. The ER collet is a very simple thing, but there are many factors that can affect its use. Generally speaking, the friction between what is clamped under the gas mine and the chuck is an important factor that affects whether the chuck is clamped. In general, the greater the friction, the tighter the clamp, and the opposite is the case when the friction is small.

2. The beginning is the problem of its axis adjustment. Only by adjusting the action points of the large axis and the small axis can a very large clamping force be displayed. Because the clamping force of the large axis is relatively large and the clamping force of the small axis is relatively large. When it is relatively small, it is very important to adjust the direction of the axis.

3. Before the body cone is installed on the spindle, first clean the chuck cone and the machine tool spindle, and tap the end face of the body with a rubber hammer or a wooden hammer to ensure tightness and firmness or tighten it with a connecting rod. According to the processing needs, select the corresponding sleeve to clean it, put it into the inner hole of the main body, push the sliding cap of the main body lightly, so that the sleeve is placed in the square hole in the main body, and then clamp the corresponding tool on the sleeve. use.

If the tapping function is used, remember to loosen the nut first. During processing, according to the needs of different torques of the tap, tighten the nut so that the tap does not slide. When putting the tap into the tap sleeve, pay attention to put the square shank into the square hole in the collet to increase the torque. Gently push the sliding cap to remove the sleeve (or replace) first. After use, clean the anti-rust, main body and collet.

MSK TOOLS offer good quality tools, collet chucks and collets, don’t hesitate to send us inquiries.

Post time: Sep-29-2022