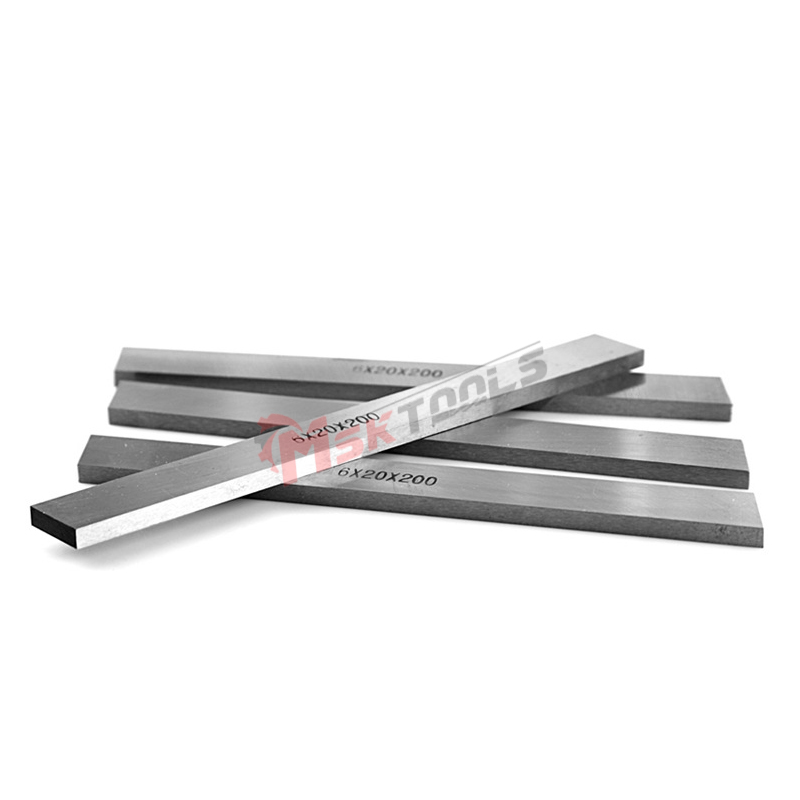

High Speed Steel Inserts: Versatile Cutting Tools for Precision and Efficiency

When it comes to cutting tough materials with precision and efficiency, nothing beats a High Speed Steel (HSS) blade. These blades are widely used in various industries due to their superior cutting performance and durability. In this blog post, we will explore the properties and applications of HSS inserts, including the popular HSS cutting inserts and HSS lathe tools.

High-speed steel blades are known for their ability to withstand the high temperatures generated during cutting, making them ideal for heavy-duty applications. Using high-speed steel as the main material ensures that the blade maintains its hardness and sharpness even at high temperatures. This results in faster cutting speeds, increased productivity and longer tool life.

One of the most common applications for HSS inserts is metal cutting. Whether shaping, separating, or removing excess material, high-speed steel blades excel at delivering clean, precise cuts. In particular, high-speed steel cutting blades are widely used in industries such as automotive, aerospace and manufacturing. Its ability to quickly cut through a variety of metals, including steel, aluminum and brass, makes it the tool of choice for many professionals.

Another well-known high-speed steel tool in the metalworking industry is the high-speed steel lathe tool. Lathe operations require cutting tools that can withstand high rotational speeds and continuous use. High-speed steel lathe tools are designed to meet these requirements, providing superior performance and precision. From facing and threading to chamfering and grooving, these tools deliver consistent results on a variety of materials including stainless steel, cast iron and titanium.

While HSS inserts are often associated with metalcutting, their versatility extends to other materials as well. High-speed steel blades are equally effective at cutting wood, plastic, and even some composite materials. As such, they find application in carpentry, construction and other industries that require precise cutting of different materials.

Proper maintenance and handling are essential to ensure the best results from HSS blades. Regular inspection and sharpening of the blade is necessary to maintain its cutting performance. Additionally, using the correct cutting parameters such as speed, feed rate and lubrication can significantly improve tool life and productivity.

In conclusion, HSS inserts, including the popular HSS cutting inserts and HSS turning tools, are the cutting tools of choice for precision and efficiency. With their ability to withstand high temperatures and cut cleanly, they have become an integral part of various industries. Whether it's metal, wood or plastic, the HSS blades are excellent at delivering the desired results. By utilizing proper maintenance and cutting parameters, professionals can maximize the performance and life of these versatile cutting tools. So the next time you need a reliable cutting tool, consider HSS inserts, which offer unrivaled cutting performance and durability.

Post time: Aug-29-2023