MC Multi-Power Super Vise

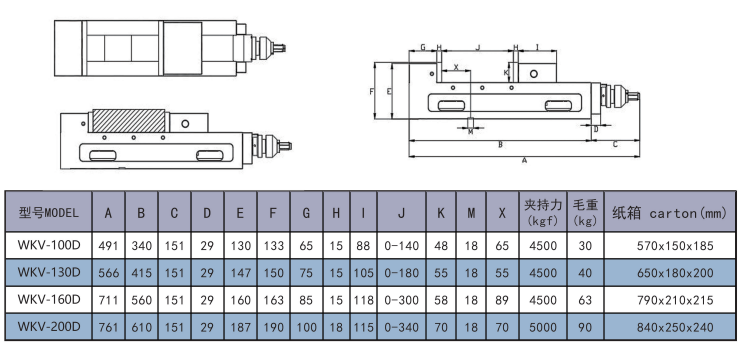

The MC Multi-Power Super Vise precision bench vise is processed and ground by multiple precision techniques and is suitable for precision machining operations on vertical and horizontal machining centers. The entire structure is cast from high-ductility ductile iron. The clamp body and jaws are hardened through heat treatment, featuring high precision, high wear resistance and strong clamping force. The unique patented mechanism design enables rapid pressurization and stable clamping up to 5,000 kilograms. The product is equipped with an anti-chip structure and an adjustable stop ring, which can not only effectively remove chips and extend service life, but also precisely preset and repeatedly apply a constant clamping force to ensure efficient and reliable processing.

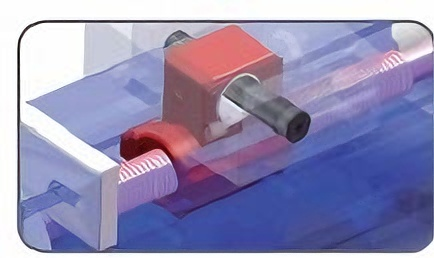

Hidden anti floating transmission mechanism

The downward force during clamping also acts,Therefore,the upward movement of the workpiece and movable body is

extremely small.The body and fixed jaw are constructed as a whole,Therefore,it can prevent the tilting of the clamp body.

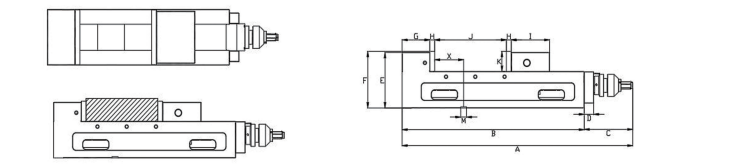

Clamping force adjustment ring

Adjusting stop ring:this simple and efective presetting device enables to preset each desired clamping force and it guarantees to repeat each clamping operation at the same clamping force.

The MC precision hydraulic vise is designed for vertical and horizontal machining centers and FMS systems, making it particularly suitable for high-precision light and heavy cutting operations. Manufactured from a single piece of high-tensile ductile iron, it incorporates a precision hydraulic force-multiplying mechanism, enabling rapid pressure increase and a powerful clamping force of up to 5000 kg.

The sliding surfaces of the vise body and the jaws are hardened to HRC42 or higher, ensuring long-term wear resistance and consistent precision. Equipped with an adjustable stop ring and chip-resistant design, it not only allows for preset and consistent clamping force but also effectively removes chips to extend service life, making it a reliable choice for precision and high-efficiency machining.

What customers say about us

FAQ

1. Q: Which machine tools is this vise suitable for?

A: This product is designed specifically for vertical and horizontal machining centers and FMS (Flexible Manufacturing Systems), and is especially suitable for high-precision, high-efficiency heavy cutting operations.

2. Q: What is the core clamping force of the vise? How is stability ensured during machining?

A: It uses a patented hydraulic force-multiplying mechanism, which can achieve rapid pressure increase, with a maximum clamping force of 5000 kg. The unique integrated design and concealed anti-floating pressure transmission mechanism effectively suppress the workpiece from floating against the moving jaws, greatly reducing tilting and ensuring superior stability during heavy cutting.

3. Q: What are the advantages of the product in terms of durability and precision?

A: The vise body is made of high-strength ductile iron in one piece. Key sliding surfaces and jaws are hardened to HRC42 or higher, providing excellent resistance to deformation, high wear resistance, and long-term precision retention.

4. Q: How is the clamping force controlled and ensured to be consistent each time?

A: The product is equipped with a simple adjustable stop ring (pressure regulating ring) preset device, allowing the operator to pre-set the required clamping force. This design ensures a consistently stable clamping force in every repeated clamping operation.

5. Q: What convenient design features does the vise have for maintenance and cleaning?

A: This product has a special chip-proof structure that effectively prevents chips from falling into the vise's interior. The internal structure also facilitates chip removal, reducing cleaning difficulty and helping to extend the equipment's lifespan.

The MC Precision Hydraulic Vise is a high-performance clamping tool designed to meet the demands of modern high-precision, high-efficiency machining. It perfectly combines strong rigidity, precise control, and convenient operation, making it a reliable solution for light and heavy cutting, especially heavy cutting and precision machining, in vertical and horizontal machining centers and FMS flexible manufacturing systems.

Design and Components: The vise is integrally cast from high-tensile-strength ductile iron (FCD600), integrating the body and fixed jaws to create unparalleled structural rigidity, fundamentally preventing tilting and deformation during clamping. All sliding contact surfaces and jaws are hardened to HRC42 or higher, ensuring excellent wear resistance and a long precision lifespan. Its core lies in the patented precision hydraulic force multiplier mechanism, which integrates a concealed anti-floating transmission mechanism, built-in chip prevention and removal design, and an adjustable stop ring (pressure regulating ring), among other ingenious components.

Functions: The core function of this product is to achieve strong, stable, and repeatable clamping. Its hydraulic mechanism can quickly generate clamping forces up to 5000 kg, sufficient to handle heavy cutting challenges. The unique anti-lift design effectively suppresses upward displacement of the workpiece and moving jaws while applying downward clamping force, ensuring machining stability. The adjustable stop ring allows the operator to precisely pre-set the required clamping force and ensures that this force is consistently repeated in every operation, protecting precision workpieces from over-clamping damage.

Applications The MC precision hydraulic vise is widely used in machining scenarios requiring high rigidity and high repeatability, especially suitable for:

Machining high-strength alloy parts in the automotive and aerospace industries.

Machining precision mold cores and inserts in the mold industry.

Achieving fast, reliable, and standardized workpiece clamping on FMS systems or automated production lines.

Any precision machining task with stringent requirements for clamping force consistency and machining stability.

Precision Machining In precision machining, even minute deformations or vibrations of the fixture directly affect the dimensional and geometric tolerances of the finished product. The integrated design and anti-lifting mechanism of this vise minimize elastic deformation and tool deflection within the clamping system itself, providing robust support for the cutting tool. With repeatable preset clamping forces, it perfectly handles the precision machining of thin-walled parts, easily deformable workpieces, or workpieces requiring repeated positioning in multiple processes.

Challenges and Considerations

In practical applications, the main challenges are balancing the enormous clamping force with the protection of precision workpieces, dealing with vibrations and chip buildup from heavy cutting, and ensuring absolute consistency in every clamping operation within an automated environment. The MC vise directly addresses these challenges through its adjustable stop ring's precise pressure control, integral hardening and chip-resistant design, and the stable force output provided by its patented hydraulic mechanism, offering process engineers a reliable and controllable clamping solution.

In summary, the MC precision hydraulic vise, with its one-piece ultra-high rigidity structure, highly efficient and reliable patented hydraulic system, and user-friendly precision control functions, successfully integrates the powerful force required for heavy cutting with the extreme stability required for precision machining. It is not only a powerful tool for improving machine tool processing efficiency and range, but also a key process equipment for ensuring consistent machining quality and achieving lean production.