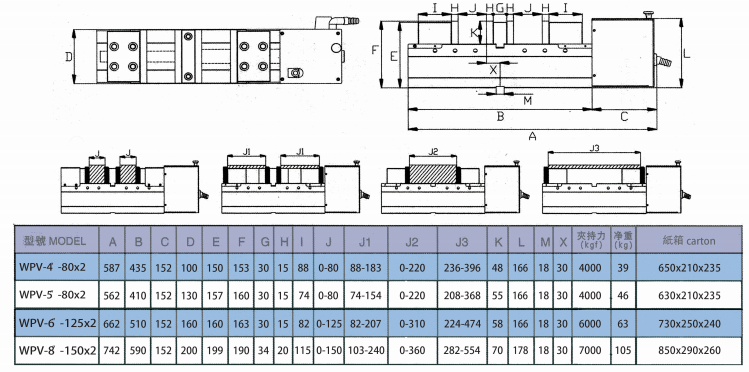

MC Super Hi-Pressure Double Vise

This vise is made of high-tensile spheroidal graphite cast iron (FCD600), making it strong, durable, and resistant to deformation. Its pneumatic-hydraulic system allows for stepless pressure adjustment from 0-6000kg, providing rapid response and automatic pressure stabilization and holding to ensure machining safety. It also supports signal interface with CNC systems, easily integrating into automated production lines and meeting the efficient clamping needs of all scenarios, from light machining to heavy cutting.

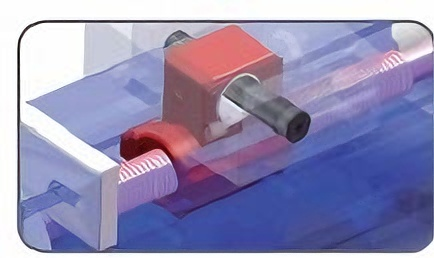

The internal floating downward pressure transmission can generate downward locking force and eliminate it Tiger

mouth board floating and working tilt

Adopting self-developed reciprocating technology Type air compressor motor,

Continuously pushing the oil circuit withair pressure Method to achieve automation.

This pneumatic hydraulic vise features a body constructed from high-strength spheroidal graphite cast iron (FCD600), boasting excellent tensile strength and resistance to deformation, ensuring long-term stability and durability. Its clamping force can be precisely adjusted within a 0-6000kg range via a pressure regulator, enabling rapid response with an opening/closing speed of only 1.5 seconds. It also features automatic pressure maintenance and stabilization to guarantee machining safety.

The vise offers a safe clamping distance of up to 6mm and automatically matches the highest air pressure source, ensuring stable operation even during light machining of copper and aluminum or heavy cutting of cast iron. It supports signal interface with CNC systems for automatic clamping control, allowing for easy integration into automated production lines and significantly improving clamping efficiency and production intelligence.

What customers say about us

FAQ

1. What is special about the material of this vise's body? How does it ensure high precision and durability?

A: The vise body is made of high-tensile-strength spheroidal graphitized cast iron (FCD600), with a tensile strength of up to 60 kgs/mm² (approximately 80,000 psi). This material possesses extremely high strength and resistance to deformation. Simultaneously, the slides on both sides of the vise undergo a hardening heat treatment (HRC42), ensuring high precision, high wear resistance, and high tensile strength, thus maintaining stable performance even under harsh conditions such as heavy cutting.

2. How is the clamping force of the vise adjusted? Can it adapt to different machining needs?

A: The clamping force of this product can be freely adjusted within the range of 0-6000 kg using a pressure regulator. When performing light machining of copper and aluminum products or heavy cutting of cast iron blanks, the user can set the pressure as needed. The system has automatic pressure holding and stabilization functions, ensuring stable clamping force even with fluctuations in the pneumatic power source pressure, safely and reliably adapting to various machining conditions.

3. How does the product achieve automated integration and operation? What is the opening and closing speed?

A: This vise is designed for automated production. It can interface with a CNC system to achieve automatic clamping and loosening, completing fully automated clamping. It can also be operated manually via a switch, electric valve, or machine tool controller. Its opening and closing speed is only 1.5 seconds, and the safe clamping distance is up to 6mm, greatly improving production efficiency while ensuring operational safety.

4. What unique design features prevent workpiece floating or tilting?

A: The vise uses a built-in floating downward pressure transmission mechanism. This mechanism generates a locking force during clamping, effectively eliminating the floating of the vise jaws and the tilting of the workpiece, ensuring that the workpiece is firmly and flatly fixed during processing, thereby improving processing accuracy.

5. What is the core technology of the drive system? How does it work?

A: This product uses a self-developed reciprocating pneumatic motor as its core drive technology. Its working principle is to use air pressure to continuously drive the oil circuit, combining the high response speed of pneumatics with the smoothness and power of hydraulics. This method not only achieves fast and powerful clamping action, but also ensures the stability and reliability of the system operation, which is the key to achieving automated and efficient production.

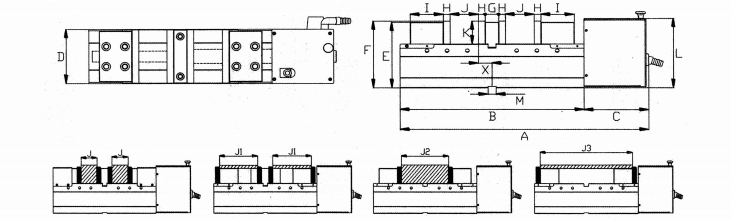

This series of pneumatic hydraulic vises utilizes a one-piece molded high-strength ductile iron (FCD600) vise body, designed for rigidity and durability, and resistant to deformation. Its core advantages lie in its integration of high clamping force (adjustable from 0-6000kg), rapid opening and closing (only 1.5 seconds), and intelligent control, aiming to provide a highly efficient, stable, and safe automated clamping solution for modern precision machining.

Design and Composition:

Rugged Body: The vise body is made of high-tensile-strength ductile iron (FCD600), possessing excellent mechanical properties and stability.

Core Drive: An internally developed reciprocating pneumatic motor continuously drives the internal hydraulic circuit via air pressure, achieving smooth and powerful power output.

Precision Structure: The side slide rails are heat-treated and hardened (HRC42) to ensure high precision and high wear resistance. A unique internal floating downward pressure transmission mechanism generates a locking force during clamping, effectively preventing the vise from floating and the workpiece from tilting.

Intelligent Interface: Equipped with a standard control interface, allowing seamless integration with external signal systems.

Features

Wide-Range Adjustable Clamping Force:** The clamping force can be freely and precisely set from 0 to 6000 kg via a pressure regulator, adapting to various machining needs, from heavy cutting of lightweight aluminum and copper to cast iron blanks.

Rapid Response and Safety: Opening and closing action is rapid, requiring only 1.5 seconds; a 6mm safety clamping distance is provided to prevent operational accidents.

Automatic Pressure Stabilization and Maintenance:The system automatically finds and maintains the highest stable air pressure source, ensuring continuous and constant clamping force even during air pressure fluctuations, preventing workpiece loosening.

Automation Integration: Supports direct control of clamping and releasing via manual switches, solenoid valves, or machine tool controllers, easily integrating into automated production units or unmanned production lines.

Applications:This vise is ideal for modern machining environments that demand efficiency and precision, especially suitable for:

CNC Machining Centers: Enables rapid automatic workpiece clamping, significantly reducing auxiliary time.

Batch Parts Production: Stable automatic clamping ensures continuous and consistent machining quality.

Flexible Manufacturing System (FMS): Easily integrated into complex automated production lines via standard signal interfaces.

Precision Machining: Its design fully considers the requirements of high-precision machining:

High-rigidity clamping body and hardened slide rails ensure positioning accuracy under heavy cutting loads and long-term geometric stability.

Floating pressure and anti-tilt design fundamentally reduce machining errors caused by clamping deformation, making it particularly suitable for precision workpieces with high requirements for flatness and perpendicularity.

Challenges and Considerations: Air Source Quality: To ensure optimal performance and lifespan, a stable and clean compressed air source is required.

System Integration: When planning a fully automated production line, the interlocking logic between the vise control signals and the machine tool or central control system must be considered in advance.

Workpiece Adaptability: For highly specialized or easily deformable workpieces, specialized fixtures or jaws may be required.

In summary, this pneumatic hydraulic vise, through its innovative built-in floating downward transmission and reciprocating pneumatic motor drive design, successfully integrates powerful clamping force, rapid cycle speed, intelligent pressure holding and stabilization functions, and convenient automation integration capabilities. It not only solves the pain points of workpiece floating and tilting in traditional clamping but also, through its reliable performance, becomes a key contributor to improving CNC machine tool utilization, achieving efficient and precise machining, and promoting the upgrading of production automation.