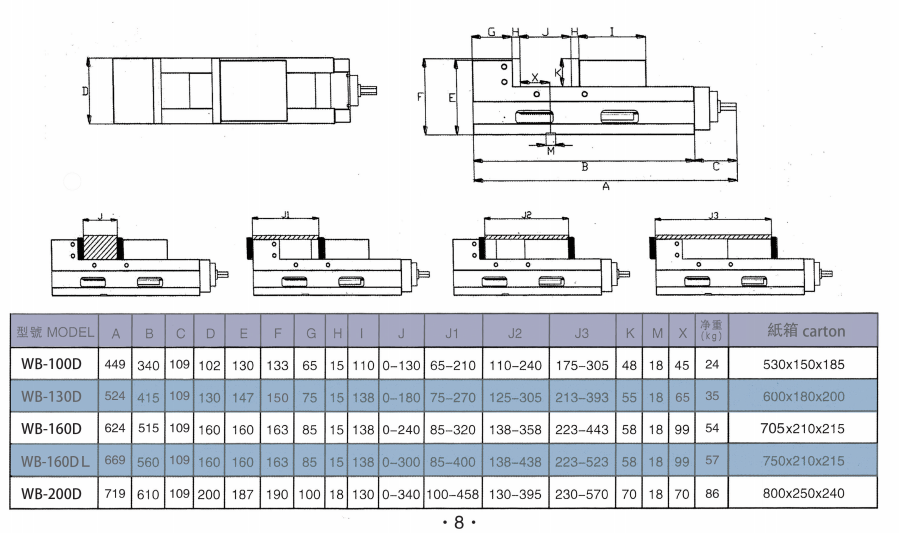

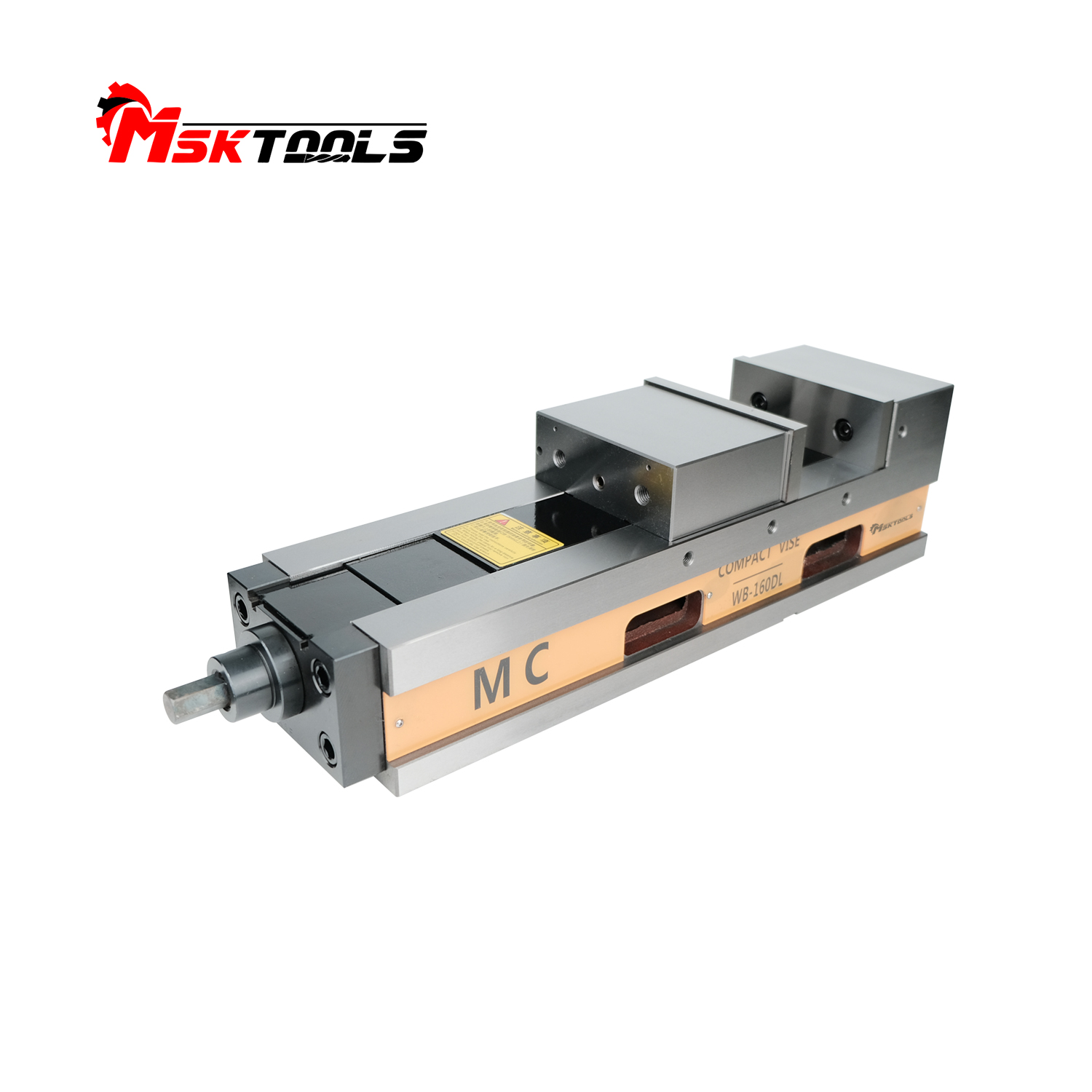

MC Preicision Machine Vise (WB)

The MC Precision Machine Vise is a fixed-angle precision vise made of high-strength ductile iron (FCD600). The body and sliding surface are hardened to HRC42° to ensure high rigidity, high precision, and excellent wear resistance. It is equipped with adjustable screws for the moving block and multiple anti-scraping designs, which can effectively maintain long-term processing accuracy and extend service life. Four clamping opening options are provided, optimized for light cutting and fine cutting in both vertical and horizontal comprehensive machining centers.

Hidden anti floating transmission mechanism

The downward force during clamping also acts,Therefore,the upward movement of the workpiece and movable body is

extremely small.The body and fixed jaw are constructed as a whole,Therefore,it can prevent the tilting of the clamp body.

This type of angle-fixed/Keppel-type precision vise is specially designed for light cutting and precision cutting in vertical or horizontal comprehensive machining centers. It is manufactured by a single-piece process using high tensile strength spherical graphite cast iron (FCD600) and undergoes sliding surface hardening treatment with an HRC42° hardness, ensuring extremely high rigidity, wear resistance and accuracy retention.

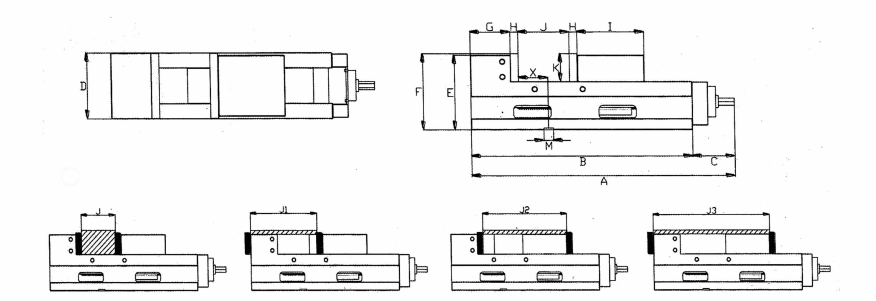

The product features a precise anti-scraping structure, which effectively prevents iron filings from entering the internal screw. It is equipped with movable blocks for adjusting the screws, allowing for immediate calibration of the optimal clamping accuracy. Additionally, it offers four different clamping opening options to meet various processing requirements.

What customers say about us

FAQ

1.Q: What types of machines and processing methods is this precision vise mainly suitable for?

A: It is specifically designed for vertical or horizontal multi-purpose machining centers, and is suitable for light cutting and precision cutting processing. It can effectively meet the requirements of high-precision processing.

2. Q: What are the advantages of the material and structure of the pliers, and how is precision and lifespan guaranteed?

A: The body of the pliers is made of high-strength spherical graphite cast iron (FCD600) in a single piece. The key sliding surfaces and jaws undergo HRC42° hardening treatment. This combination provides extremely high tensile strength, wear resistance, and rigidity, effectively resisting deformation, thereby ensuring long-term stable high precision and a long service life.

3. Q: How does the product handle the problem of iron filings generated during processing?

A: This vise adopts a special anti-iron-filament design, which can effectively prevent the iron filings produced during processing from entering the internal transmission screw and mechanism, avoiding the degradation of accuracy, jamming or damage caused by the accumulation of iron filings, simplifying maintenance and extending the service life.

4. Q: How exactly does the "anti-floating" design work?

A: The vise is equipped with a built-in anti-floating transmission mechanism. When clamping the workpiece, this mechanism generates a downward force, effectively suppressing the upward floating tendency of the workpiece and the movable jaw. Additionally, the body and the fixed jaw are constructed as an integrated unit, further preventing the jaw from tilting under force, ensuring the stability and accuracy of the clamping.

5. Q: What are the features of the product in terms of adaptability and precision adjustment?

A: Firstly, this vise offers four different clamping opening sizes for selection, providing greater adaptability. Secondly, it is equipped with an adjustable screw for the movable block, allowing users to conveniently fine-tune and calibrate the clamping accuracy of the vise at any time to restore or maintain the optimal working condition.

This product is a type of angle-fixed/Keinbide precision vise, designed specifically for vertical or horizontal comprehensive machining centers as a professional clamping tool. It aims to achieve high precision and stability, and is particularly suitable for light cutting and precision cutting operations.

Design and Composition

The main body of the vise is integrally cast from high tensile strength spherical graphite cast iron (FCD600, tensile strength 60 kgf/mm²). The sliding contact surface and the jaws have undergone heat treatment, achieving a hardness of HRC42°, ensuring the wear resistance and rigidity of the core components. The overall structure integrates a fixed body, a movable jaw, a precision screw, and a specially designed internal anti-floating transmission mechanism.

Function

Strong and stable clamping: The integrated body and fixed jaw design, combined with the anti-floating mechanism, generates a downward force during clamping, effectively preventing the workpiece and the movable jaw from floating up and preventing the clamp body from overturning.

Accuracy retention and fine-tuning: Equipped with adjustable screw blocks, allowing users to calibrate and restore the optimal clamping accuracy of the vise at any time.

Long-lasting protection: With a special anti-scraping design, it can prevent iron filings from the processing from entering the internal transmission screws and mechanisms, ensuring smooth operation and long service life.

Application program

This vise is an ideal fixture for the field of precision mechanical processing. It is widely used in mold manufacturing, precision part production, jig fabrication, etc., in situations that require high repeatability positioning accuracy and excellent rigidity. It is particularly suitable for performing milling, drilling and other processes on machining centers.

Precision mechanical processing

To meet the extreme stability requirements of precision machining, this vise not only has a sturdy material and proper heat treatment, but also features anti-floating and anti-scraping designs specifically addressing the common problems of "tool deviation" and "precision wear" during the machining process. These designs provide a solid clamping foundation for continuously achieving high-quality machined surfaces.

Challenges and Considerations

In high-speed and high-precision machining, even minor deformations, vibrations, or iron filings from the fixture itself can become bottlenecks affecting the quality of the finished product. This vise tackles these challenges systematically by enhancing the rigidity of the body, optimizing the force transmission path (to prevent floating), and sealing the key moving components (to prevent iron filings).

In summary, this precision vise is equipped with an integrated high-strength cast iron body, a hardened surface with an HRC42° hardness, an internal anti-floating mechanism, adjustable precision design, and comprehensive anti-scraping protection. It forms a complete set of precision clamping solutions. It combines rigidity, precision, and durability, and is a key equipment for enhancing the production efficiency and processing quality of machining centers.