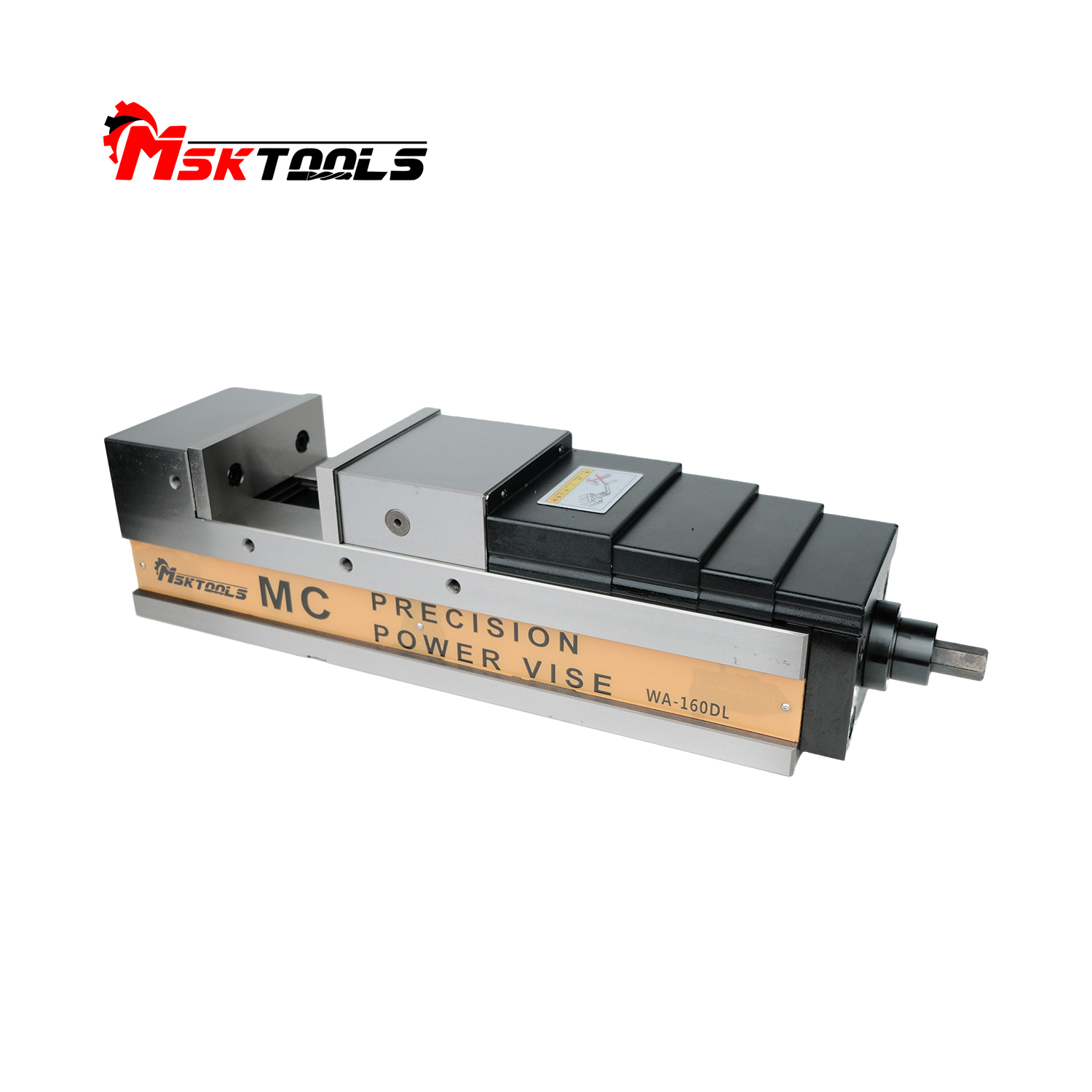

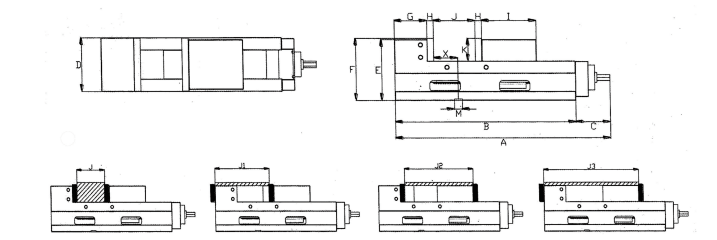

MC Preicision Machine Vise

The MC Precision Machine Vise is designed for vertical and horizontal machining centers. Made of high-strength ductile cast iron, it offers excellent resistance to deformation and a long service life. It features an adjustable moving jaw and a chip-resistant structure, ensuring stable and efficient performance for both light and precision machining operations.

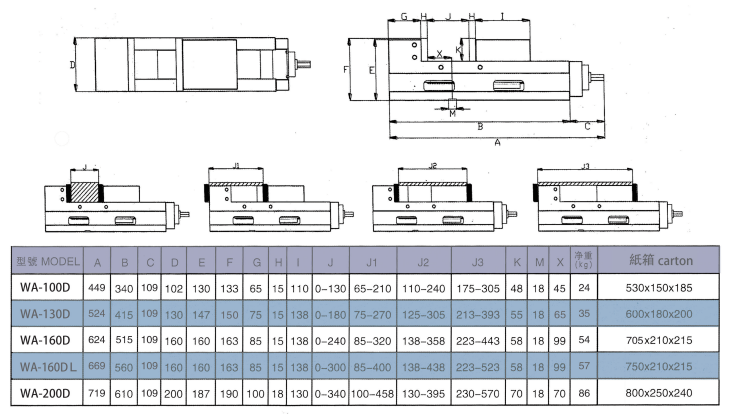

Hidden anti floating transmission mechanism

The downward force during clamping also acts,Therefore,the upward movement of the workpece and movable body is

extremely small.The body and fixed jaw are constructed as a whole,Therefore,it can prevent the tilting of the clamp body.

Angle-locking/Kempf-style precision vises are designed specifically for vertical and horizontal machining centers, meeting the demands of both light and precision machining. The vise body is made from a single piece of high-tensile strength ductile iron, with hardened sliding surfaces to ensure high precision and wear resistance.

It features four selectable clamping openings and a chip-proof design to effectively prevent metal chips from entering, extending its service life. The movable jaw is equipped with a precision adjustment screw for easy calibration, combining powerful clamping with convenient operation.

What customers say about us

FAQ

1.What equipment is this precision vise suitable for? What are its core application scenarios?

This product is designed for vertical and horizontal machining centers and is suitable for light and precision machining applications requiring high accuracy. It is an ideal clamping device for precision parts processing.

2.What are the advantages of the vise's material and structure, and how are accuracy and durability ensured?

The vise body is made of integrally formed high-strength ductile cast iron (FCD600), and the sliding surfaces are hardened to HRC42°, providing both high tensile strength and wear resistance. The fixed jaw is integrated with the body, effectively preventing the vise body from tilting and ensuring high accuracy and stability during long-term use.

3.What special designs does the product have to prevent workpiece lifting and chip intrusion?

The vise has a built-in anti-lifting transmission mechanism that generates a downward force during clamping, greatly reducing the lifting of the workpiece and the movable jaw. At the same time, the fully enclosed chip-proof design effectively prevents machining chips from entering the transmission screw and internal mechanisms, facilitating cleaning and extending service life.

4.What clamping options does the vise offer, and how flexible is it?

The product offers four different clamping opening sizes for users to choose from, adapting to various workpiece specifications. In addition, the movable jaw is equipped with adjustable screws, allowing users to fine-tune it at any time to restore and maintain the vise's optimal clamping accuracy.

5.What reinforcement treatments have been applied to the movable jaw and key components?

The movable jaw is also heat-treated to HRC42° hardness, ensuring that it has comparable wear resistance and deformation resistance to the main body, thus providing uniform, strong, and long-lasting clamping force across the entire clamping surface.

Angle-Locking/Kempf-Style Precision Vises are high-performance clamping tools specifically designed for vertical or horizontal machining centers, dedicated to achieving high-precision, high-stability light cutting and precision machining.

Design and Composition

This product features an integrated structural design, with the main body and fixed jaw cast as a single unit. The core is made of high-strength ductile cast iron (FCD600), and the key sliding surfaces and jaws are heat-treated to HRC42°, possessing excellent tensile strength, wear resistance, and rigidity. Its transmission system incorporates a unique anti-lifting mechanism, ensuring absolute clamping stability.

Functionality

The core function of this vise lies in its powerful anti-tilting and anti-workpiece lifting capabilities. The built-in anti-lifting transmission mechanism generates a downward force during clamping, greatly suppressing the lifting of the workpiece and the movable jaw. Combined with the integrated body design, it effectively prevents the vise from tilting during machining. Simultaneously, the four-position adjustable clamping opening and movable block fine-tuning screw provide users with flexible clamping solutions and precision calibration capabilities.

Applications

This product is perfectly suited for CNC machining centers, milling machines, and other precision machine tools. It is an ideal choice for mold processing, precision parts manufacturing, and jig and fixture production, where extremely high repeatability and machining stability are required.

Precision Machining

To ensure long-term high precision, each guide rail of the vise undergoes precision machining and polishing. Combined with robust materials and a chip-resistant design, it effectively resists deformation and wear caused by cutting forces, guaranteeing dimensional consistency during prolonged machining. It is a reliable partner for users pursuing micron-level accuracy.

Challenges and Considerations

Under demanding conditions such as high-speed and intermittent cutting, chip ingress and insufficient clamping rigidity are common challenges. This vise addresses these issues through a fully enclosed chip-resistant design, preventing chips from entering the screw and internal mechanisms, solving cleaning problems and extending service life. Its robust integrated structure and anti-lifting design directly address vibration and tool deflection problems during machining, ensuring the smoothness of the machined surface. Summary

In conclusion, the angle-locking/Kempf-type precision vise, through overall optimization of materials, structure, and detailed functions, successfully integrates high rigidity, high precision, high durability, and ease of operation. It provides a solid and reliable workpiece clamping solution for modern precision machining, and is a key piece of equipment for improving processing quality and efficiency.